Manufacturing method of 10Z copper foil hollow FPC

A production method and technology of copper foil, which is applied in the direction of multilayer circuit manufacturing, printed circuit manufacturing, and electrical connection formation of printed components, can solve problems such as uneven copper thickness in holes, signal cracking, and via breakage, so as to reduce rough surface Effects of roughness, reliable rejection, uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

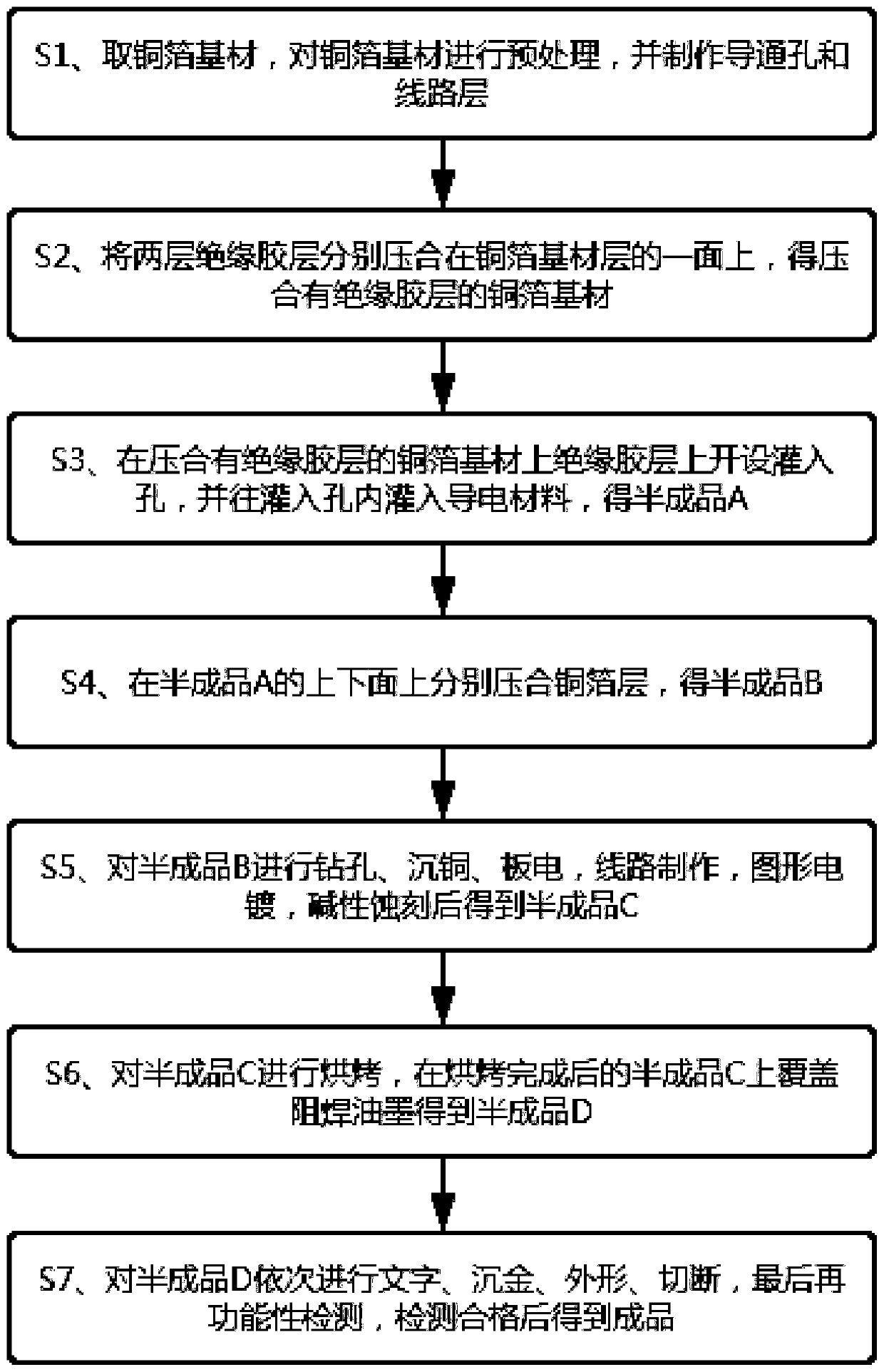

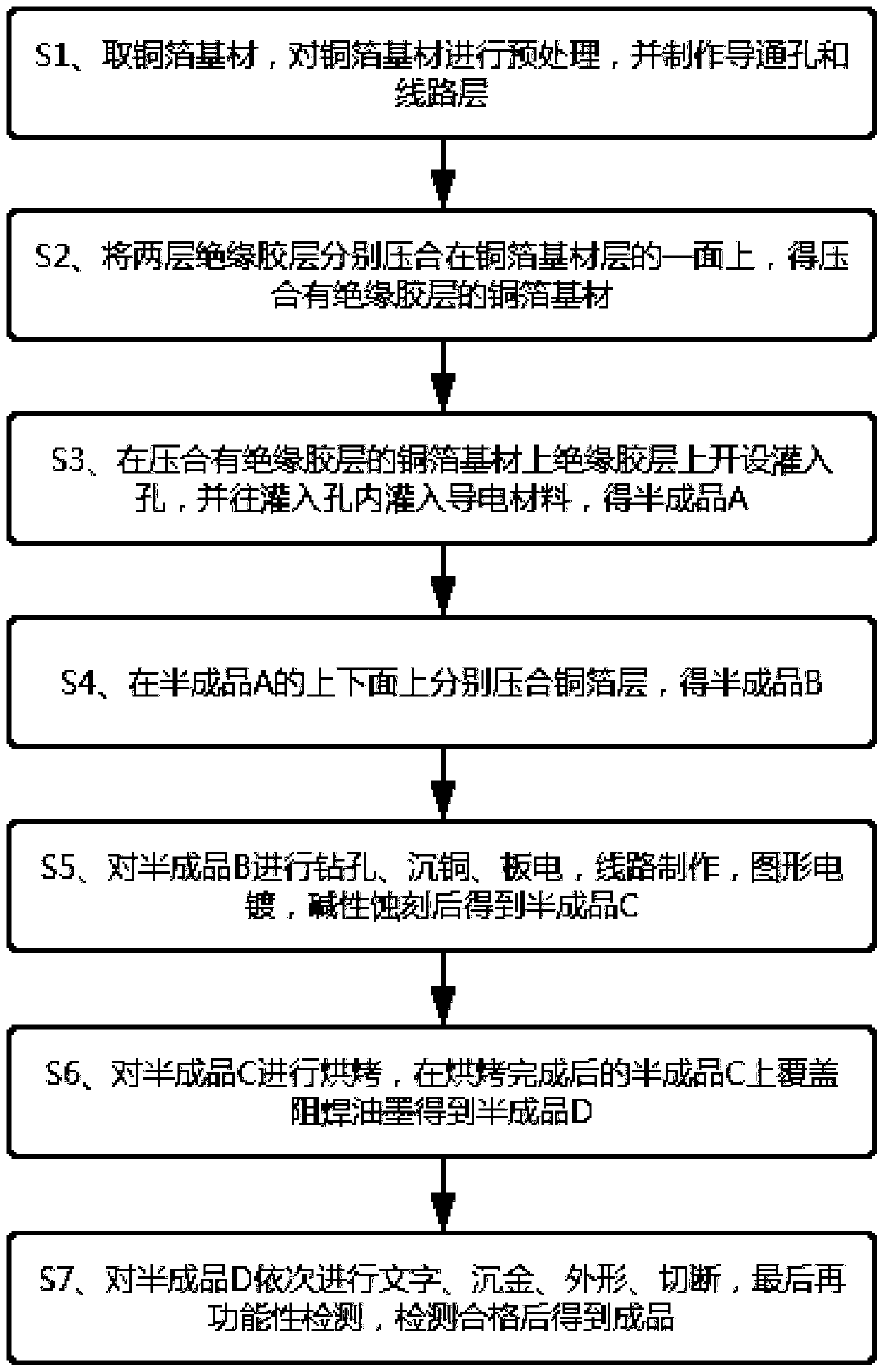

[0039] see figure 1 , a 10Z copper foil hollow FPC manufacturing method, comprising the following steps:

[0040] S1. Take the copper foil substrate, pretreat the copper foil substrate, and make via holes and circuit layers;

[0041] The copper foil substrate is a double-sided flexible copper foil substrate, and the pretreatment step of the copper foil substrate includes removing oxides, grease and impurities on the metal surface of the copper foil substrate.

[0042] The specific steps of making the through hole are: opening a via hole on the copper foil base material, attaching a masking film on the entire outer surface of the copper foil base material, the masking film is used to prevent the copper foil base material from being electroplated or etched, and the The masking film is windowed corresponding to the via holes to obtain the substrate to be electroplated, and then the substrate to be electroplated is immersed in the electroplating solution for a preset time to comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com