Clam umami peptide and preparation method and application thereof

A technology of umami peptides and clams, applied in the fields of application, food ingredients as taste improvers, multi-step food processing, etc., can solve the unfavorable development and utilization of umami peptides of clams, different taste sensations, and insufficient research on the structure of taste peptide components Sufficient and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A clam umami peptide, the preparation method of which polypeptide comprises the following steps:

[0051] (1) Preparation of freeze-dried clam boiled liquid powder: shell fresh clams and wash the clam meat, drain the water and weigh, add deionized water at a ratio of 1:3 (w / v) to liquid Homogenize, heat and cook, keep the temperature for 20 minutes after the center temperature reaches 95°C, filter through the filter cloth after the temperature drops to room temperature after the end of heating, centrifuge the filtrate at 5000r / min for 20min at 4°C, take the supernatant, freeze-dry to obtain clams Freeze-dried powder of boiled liquid.

[0052] (2) Ultrafiltration separation: redissolve the freeze-dried powder of clam boiled liquid in ultrapure water, prepare a solution with a concentration of 10mg / mL, and use an ultrafiltration membrane with a molecular weight cut-off of 3000Da to conduct ultrafiltration separation at 4°C , collect the filtrate, and freeze-dry to obtain...

Embodiment 2

[0056] (1) Preparation of freeze-dried clam boiled liquid powder: shell fresh clams and wash the clam meat, drain the water and weigh, add deionized water at a ratio of 1:3 (w / v) to liquid Homogenize, heat and boil, keep for 30 minutes after the center temperature reaches 100°C, filter through filter cloth after the temperature drops to room temperature at the end of heating, centrifuge the filtrate at 5000r / min for 30min at 4°C, take the supernatant, freeze-dry to obtain clams Freeze-dried powder of boiled liquid.

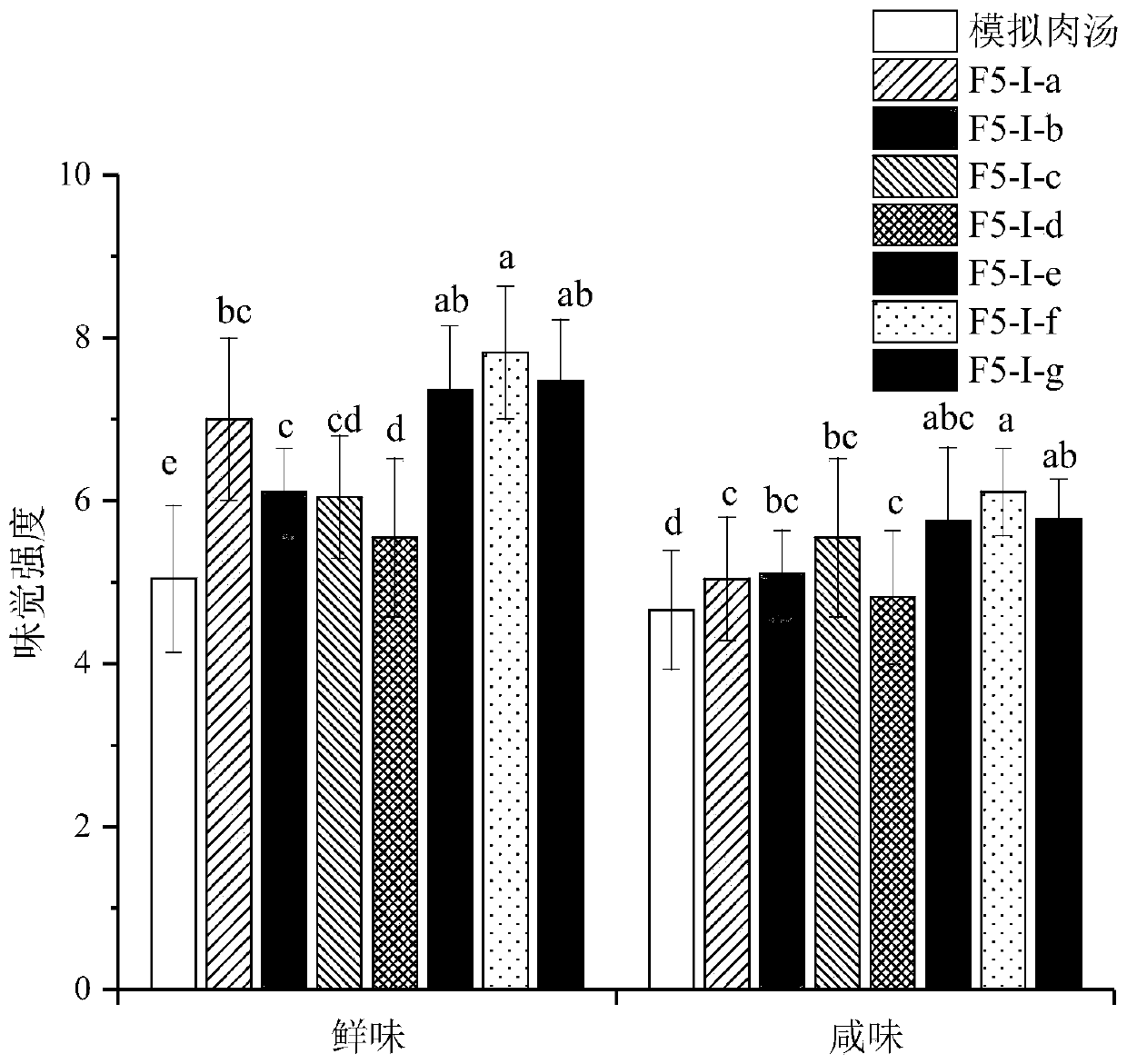

[0057] (2) ultrafiltration separation: with embodiment 1.

[0058] (3) Purification by gel chromatography: reconstitute the lyophilized ultrafiltrate powder with ultrapure water, prepare a solution with a concentration of 10 mg / mL, put it on a Sephadex G-15 gel chromatography column, and elute with ultrapure water , the elution conditions were: sample volume 2mL, flow rate 1mL / min, ultraviolet detection wavelength 220nm, the fifth peak component F5 was collected,...

Embodiment 3

[0061] (1) Preparation of freeze-dried clam boiled liquid powder: shell fresh clams and wash the clam meat, drain the water and weigh, add deionized water at a ratio of 1:3 (w / v) to liquid Homogenize, heat and cook, keep the temperature for 25 minutes after the center temperature reaches 95°C, filter through filter cloth after the temperature drops to room temperature after heating, centrifuge the filtrate at 5000r / min for 25min at 4°C, take the supernatant, freeze-dry to obtain clams Freeze-dried powder of boiled liquid.

[0062] (2) ultrafiltration separation: with embodiment 1.

[0063] (3) Purification by gel chromatography: same as in Example 2.

[0064] (4) Purification by RP-HPLC: Same as in Example 1, to obtain freeze-dried clam umami peptide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com