A seasoning without adding synthetic flavoring agent and its preparation method

A seasoning and umami agent technology, which is applied in the field of preparation of seasoning without adding synthetic umami agents, can solve the problems of fishy smell and bitterness treatment, and achieve the effect of reasonable proportioning, easy realization and pleasant fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

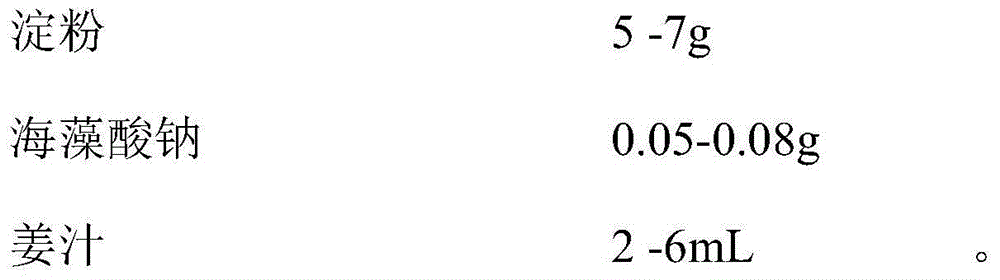

[0029] A seasoning without added synthetic umami comprising the following components:

[0030]

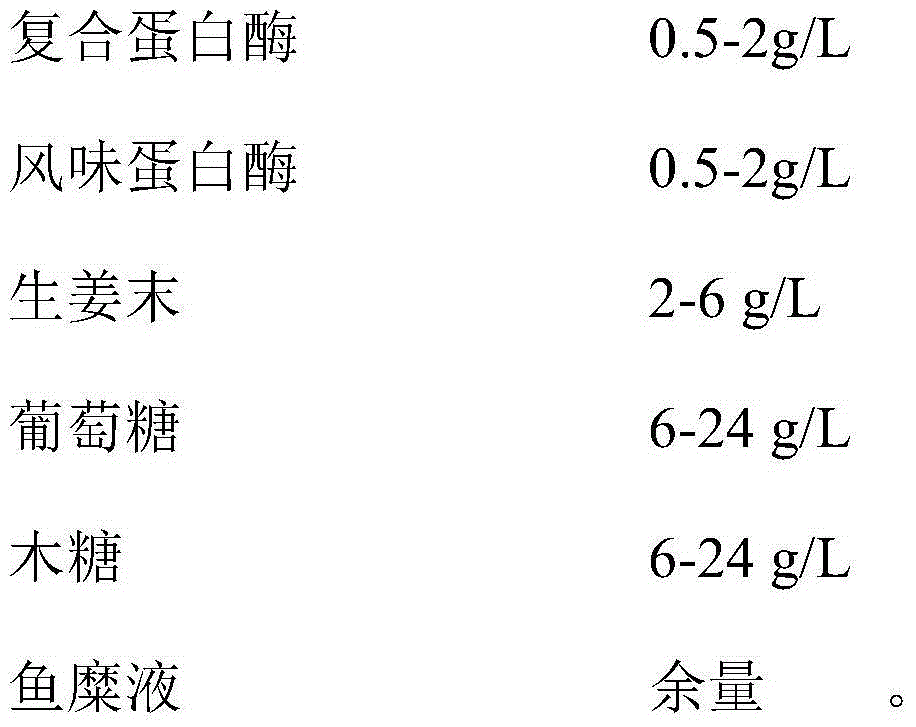

[0031] The enzymolysis solution described in the present invention is made of the following components:

[0032]

[0033]

[0034] The surimi liquid is prepared by mixing crushed tilapia bones and water at a solid-to-liquid ratio of 1:1.

Embodiment 2

[0036] A seasoning without added synthetic umami comprising the following components:

[0037]

[0038] The enzymolysis solution described in the present invention is made of the following components:

[0039]

[0040] The surimi liquid is prepared by mixing crushed fish slag and water at a solid-to-liquid ratio of 1:3.

Embodiment 3

[0042] A seasoning without added synthetic umami comprising the following components:

[0043]

[0044] The enzymolysis solution described in the present invention is made of the following components:

[0045]

[0046] The surimi liquid is prepared by mixing broken visceral crucian carp and small marine miscellaneous fish with water at a solid-to-liquid ratio of 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com