Sweating device for poria cocos processing

A poria cocos and cylinder technology, which is applied in the field of sweating devices for poria cocos processing, can solve the problems of troublesome sweating operation, time-consuming and labor-intensive operations, and achieve the effects of saving pick-and-place time, high flexibility of use, and reducing water vapor residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

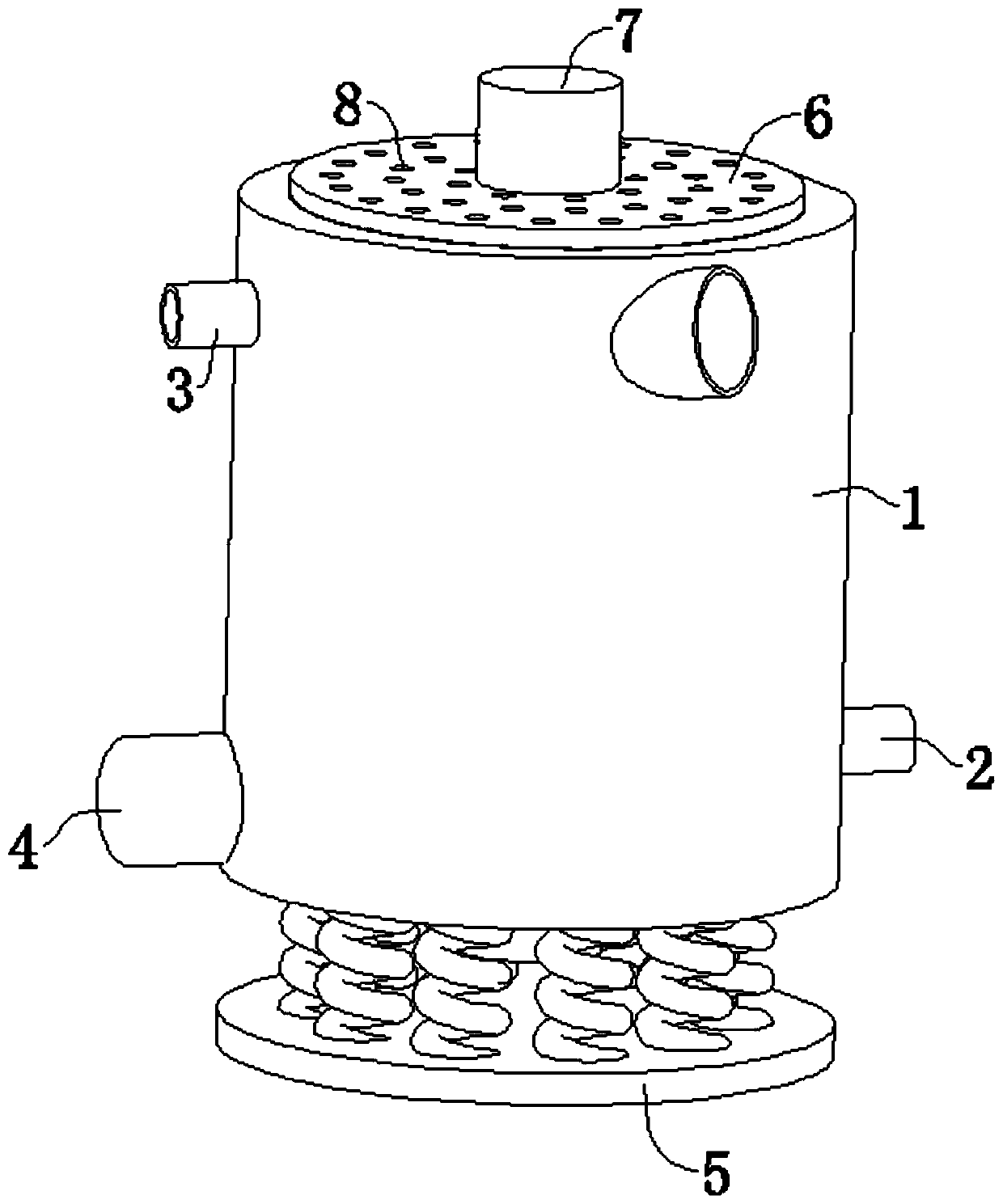

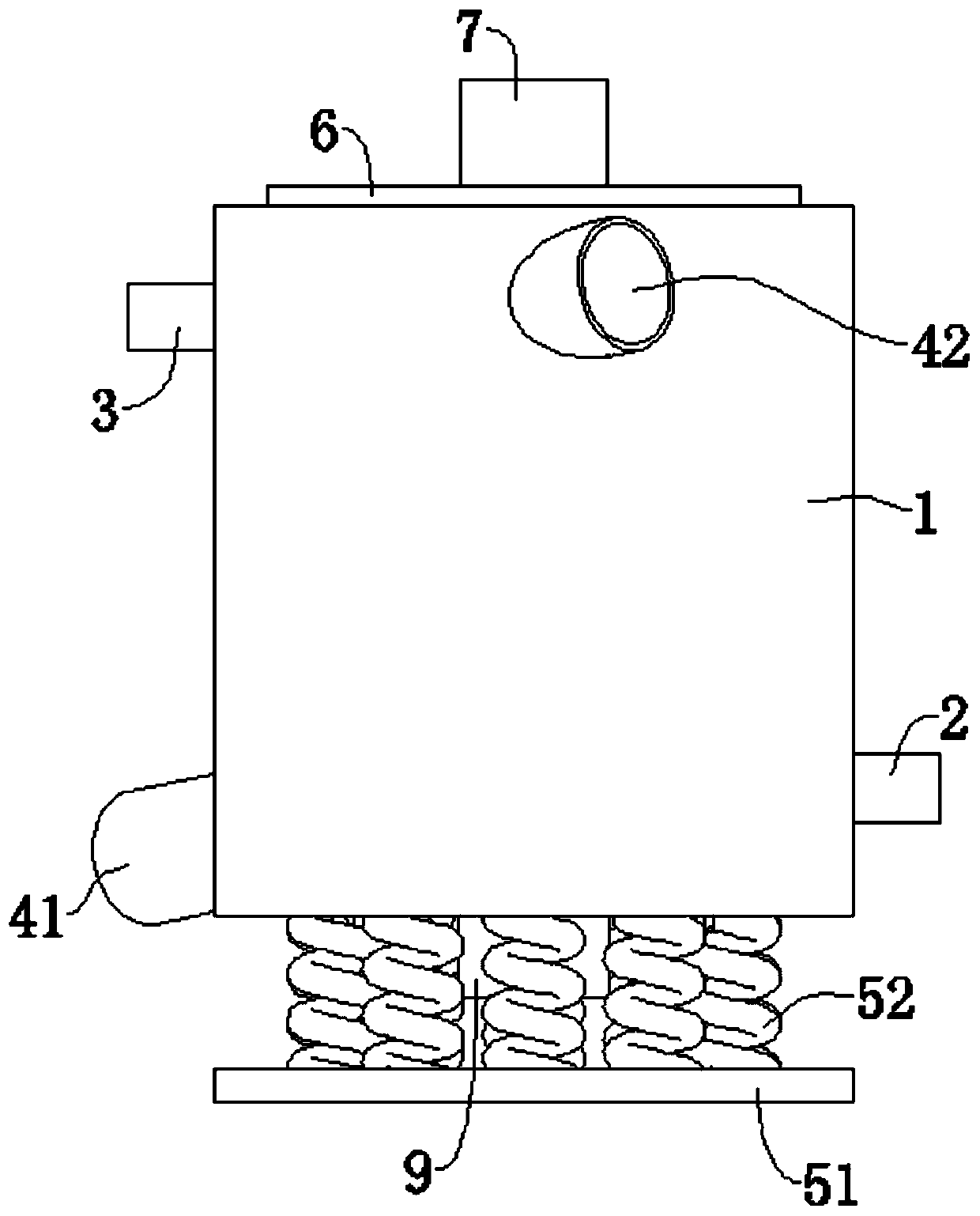

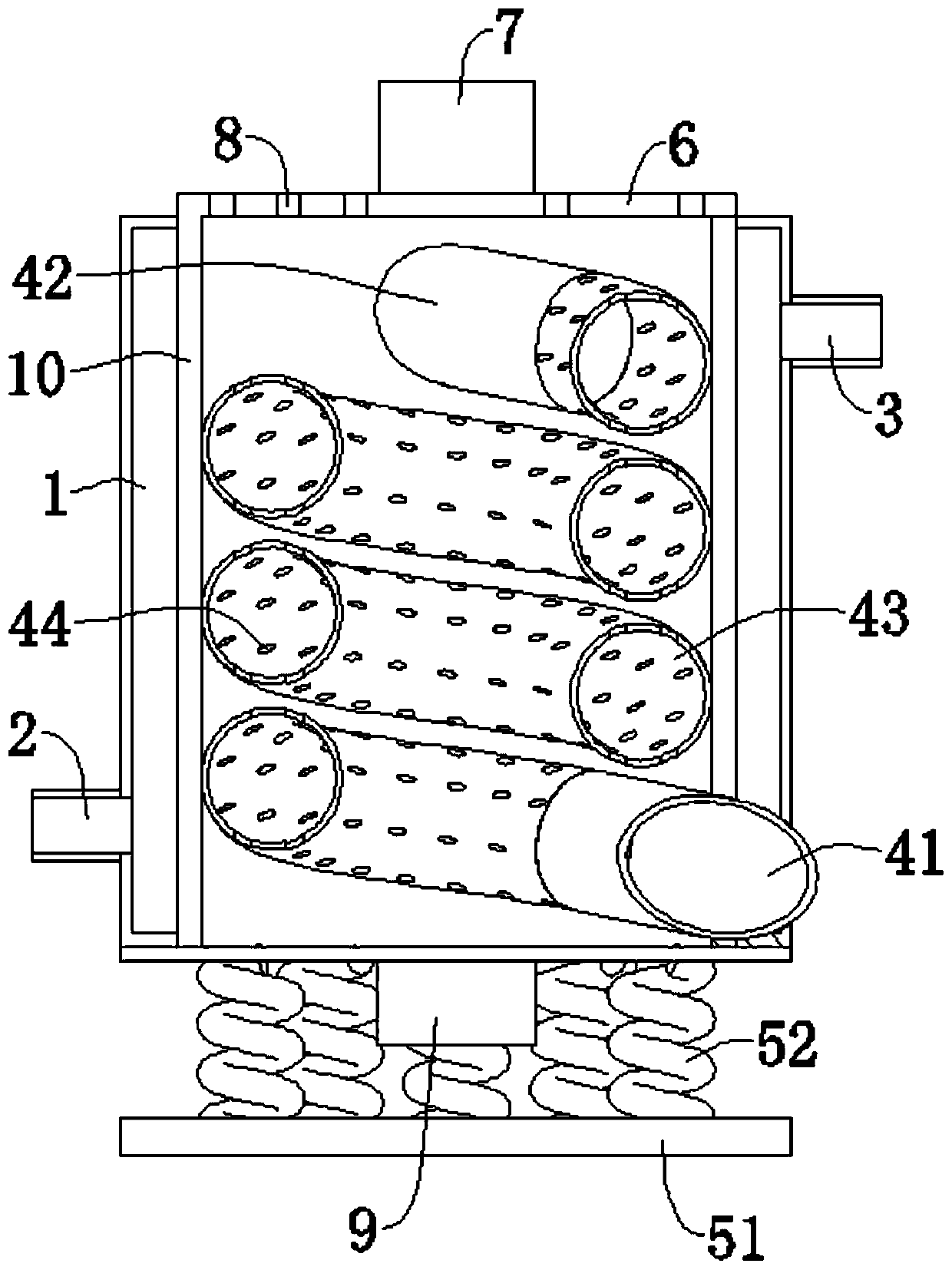

[0030] Embodiment: a kind of Poria cocos processing uses sweating device, as Figure 1-4 As shown, it includes a cylinder 10, a spiral tube 4, a vibrator 9 and a shock-absorbing base 5. The cylinder body 10 is a vertical cylinder body and the upper end cover is provided with a cover body 6 , and a plurality of circular cooling holes 8 are opened on the cover body 6 , and the plurality of circular cooling holes 8 are evenly distributed on the cover body 6 . The spiral tube 4 is located in the cylinder body 10 and is spirally arranged from top to bottom. The spiral tube 4 is fixed on the inner wall of the cylinder body 10. The inner diameter of the spiral tube 4 should satisfy that multiple tuckahoes can roll freely in the spiral tube 4 at the same time. In order to stably support the spiral tube 4 in the cylinder body 1 , the inner wall of the cylinder body 1 can be provided with a spiral cap, and the spiral tube 4 is supported on the spiral cap to improve the overall strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com