Combined energy absorption structure

An energy-absorbing structure and combined technology, applied in vehicle safety arrangements, railway car body parts, bumpers, etc., can solve the problem of reducing energy absorption of filling structures, and achieve increased deformation form and force stability, and stable buffer force. , the effect of increasing the average compressive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

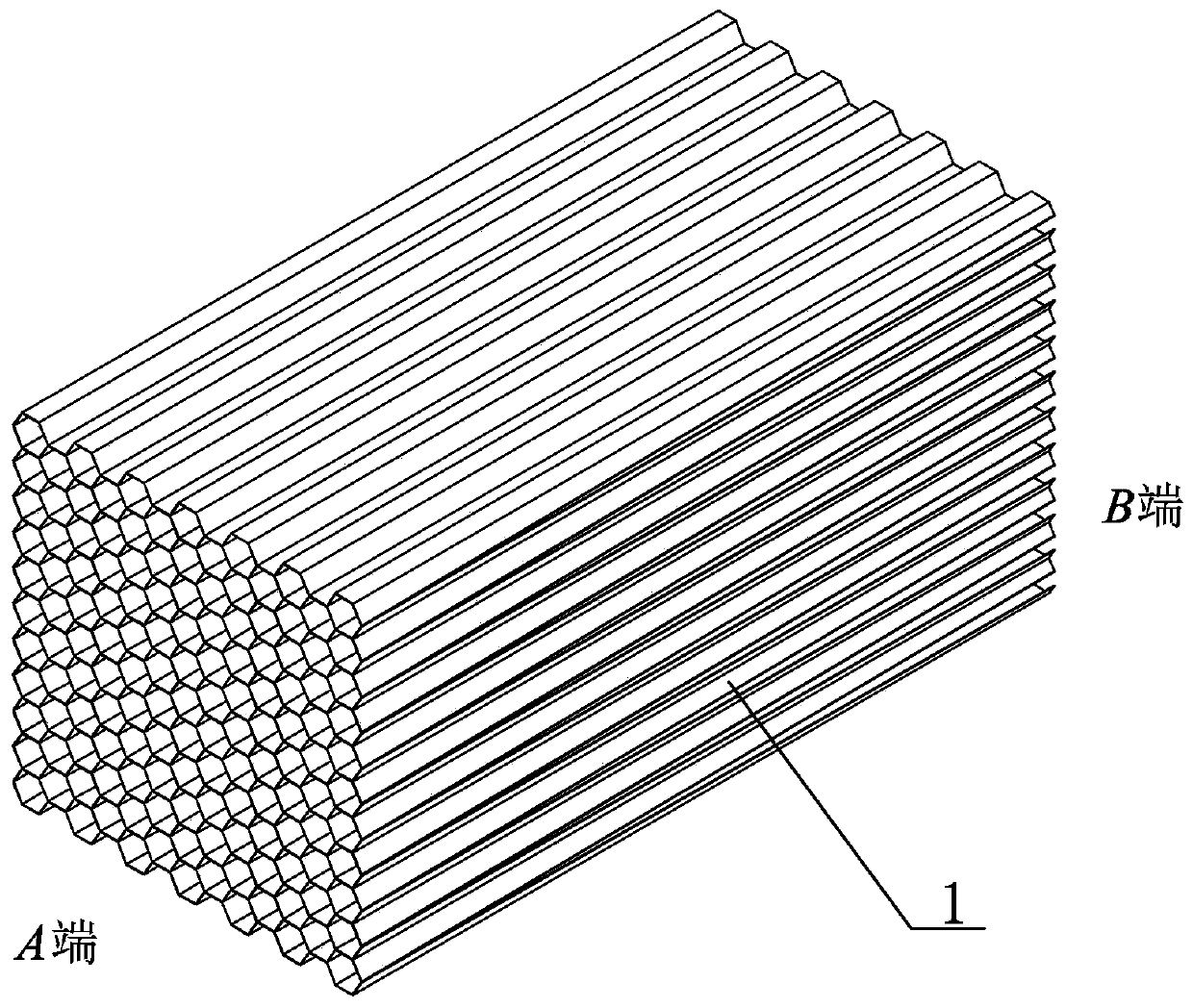

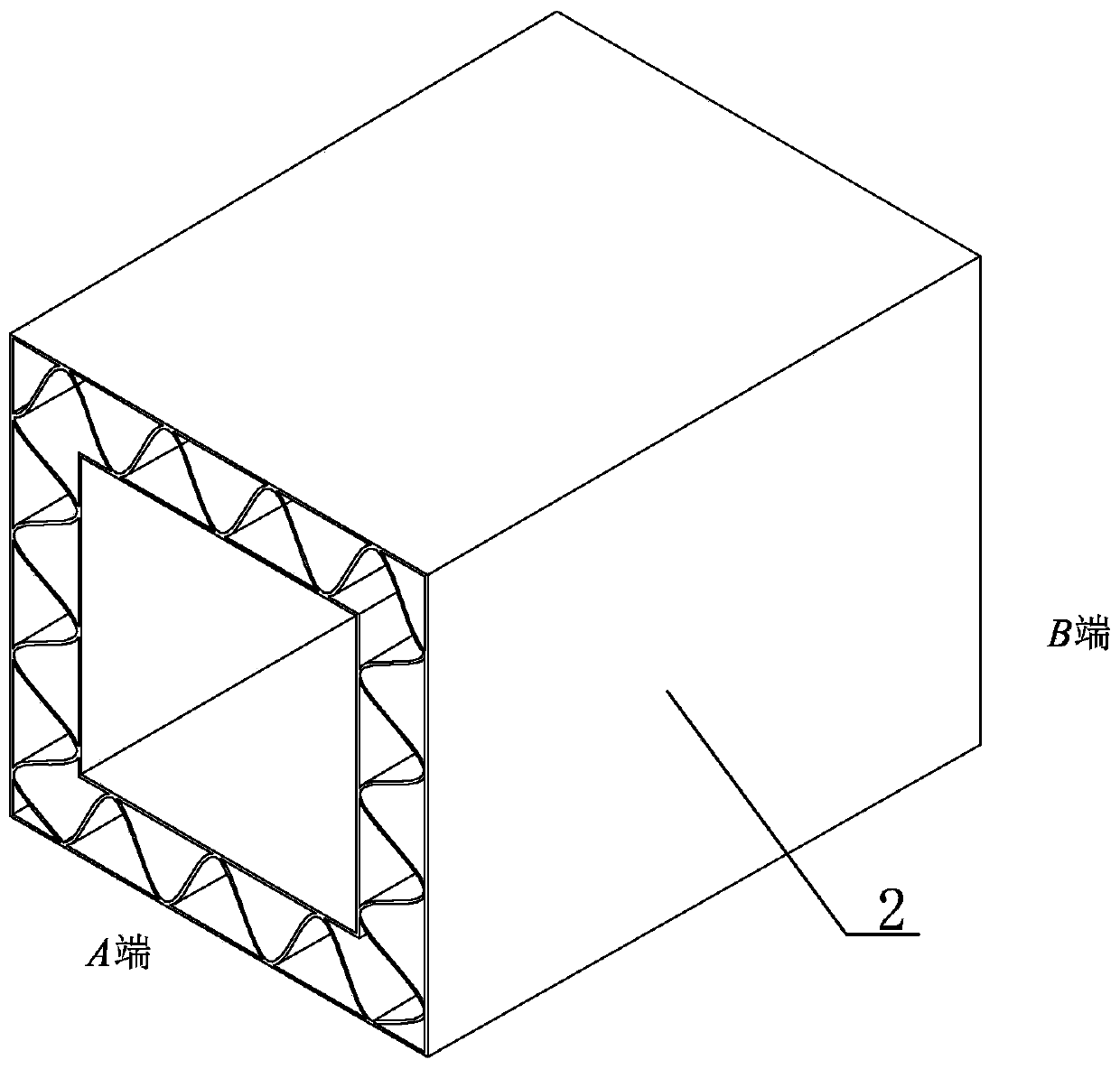

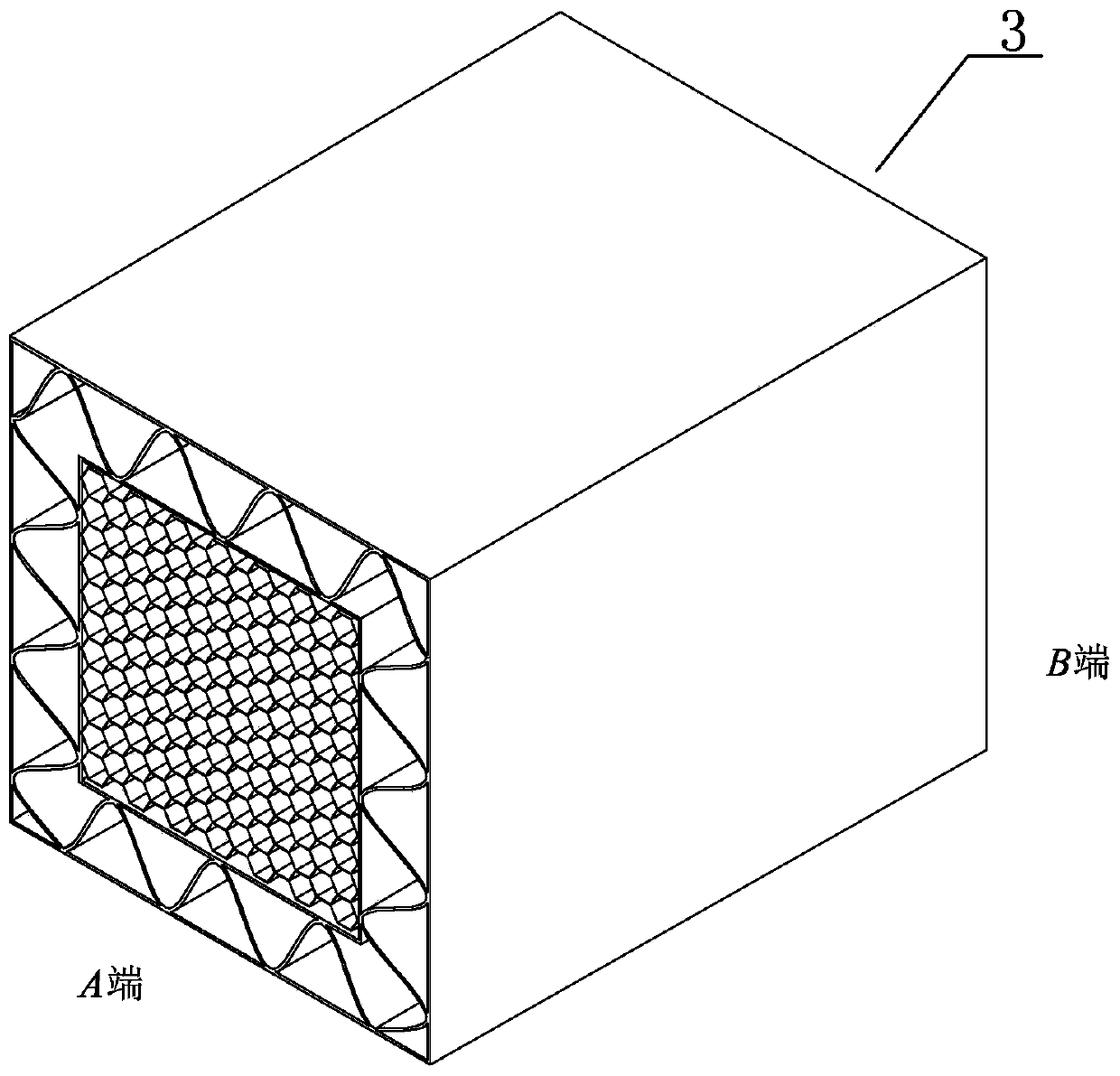

[0031] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a combined energy-absorbing structure of this embodiment includes a buffer energy-absorbing block 1 and a porous thin-walled tube 2, the buffer energy-absorbing block 1 is a variable thickness energy-absorbing block, and the porous thin-walled tube 2 is a variable-thickness thin The wall pipe, the buffer energy-absorbing block 1 is filled into the porous thin-wall pipe 2 to form the energy-absorbing structure 3 .

[0032] The present invention adopts a porous thin-walled tube with variable thickness, and simultaneously fills the porous buffer and energy-absorbing material into the porous thin-walled tube with variable thickness;

[0033] The invention is not limited to the field of rail train energy absorption, but also can be used in other fields with buffer systems such as automobiles and aerospace.

specific Embodiment approach 2

[0034] Specific implementation mode two: combination Figure 1 to Figure 4 To describe this embodiment, the energy-absorbing block 1 of this embodiment is a honeycomb block, a foam block or a rubber block. Such a design has a wide range of applications. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0035] Specific implementation mode three: combination Figure 1 to Figure 4 The present embodiment will be described. The strength of the energy-absorbing block 1 of the present embodiment is equal strength or variable strength. Such a design can cooperate with the inner thin-walled tube 4, the outer thin-walled tube 5 and the stiffened plate 6 to adjust the buffering force of the combined structure to meet different application scenarios, such as: if the buffering force gradually increases, the buffering force is constant The buffer energy-absorbing system whose value and buffer force gradually decrease. . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com