Quick and labor-saving opening and closing handle mechanism for pressure-resistant hatch cover

A technology for pressure-resistant hatches and hatch covers, which is applied in the field of hatch cover opening and closing, which can solve the problems of slow opening of pressure-resistant hatch covers, high labor intensity of personnel, and delay of escape time, so as to reduce operating force and labor intensity of personnel, Inexpensive to manufacture, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

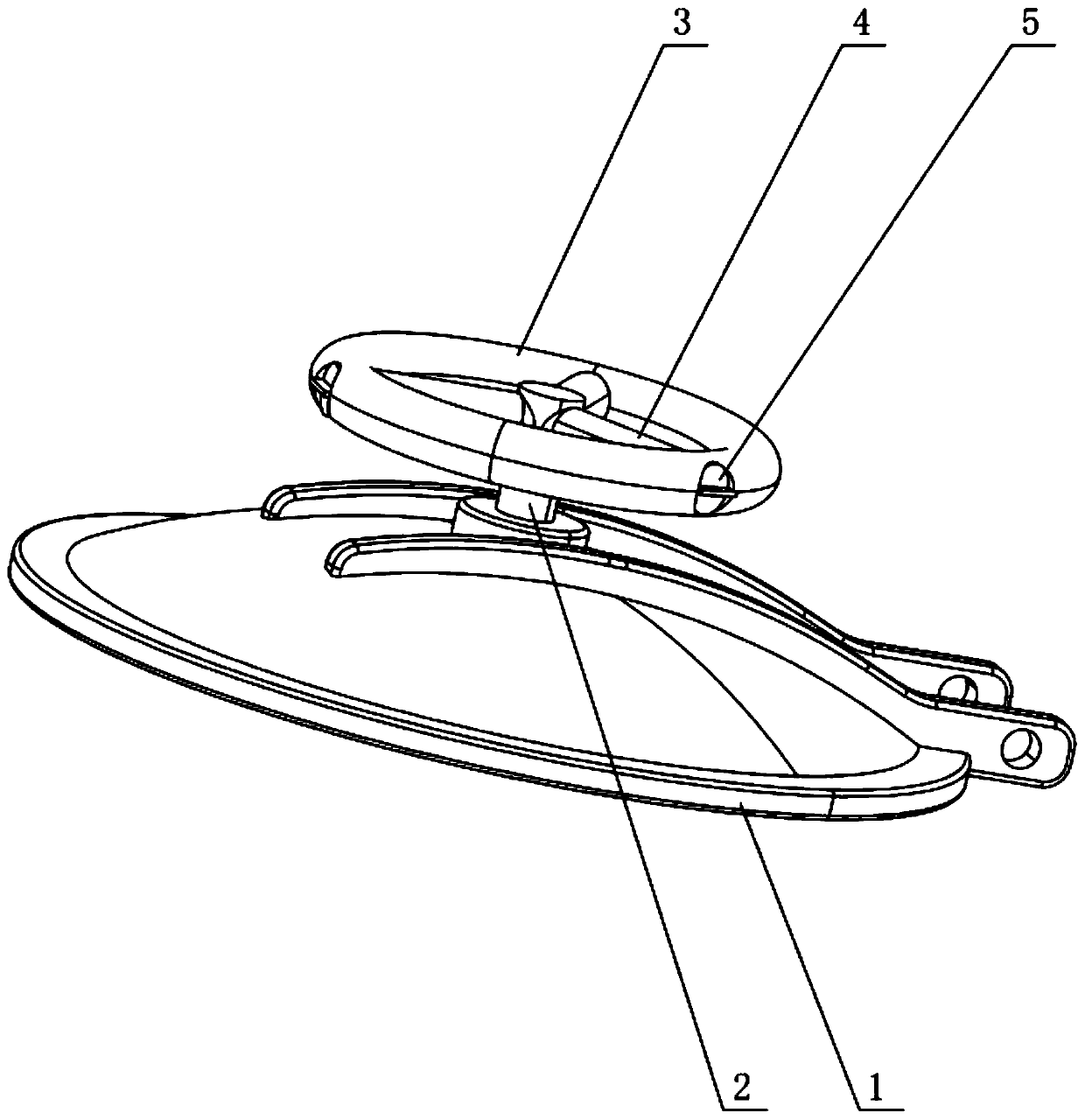

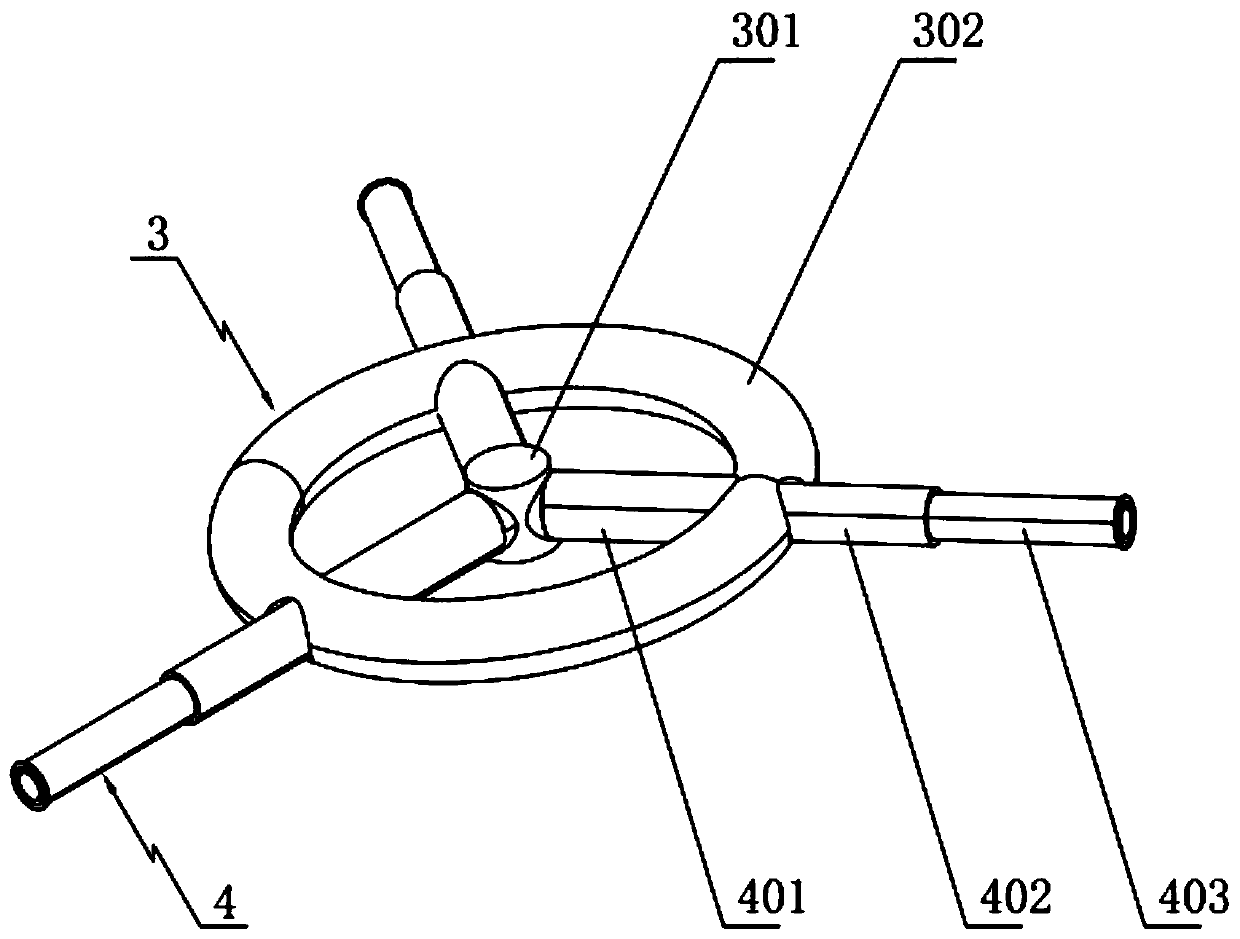

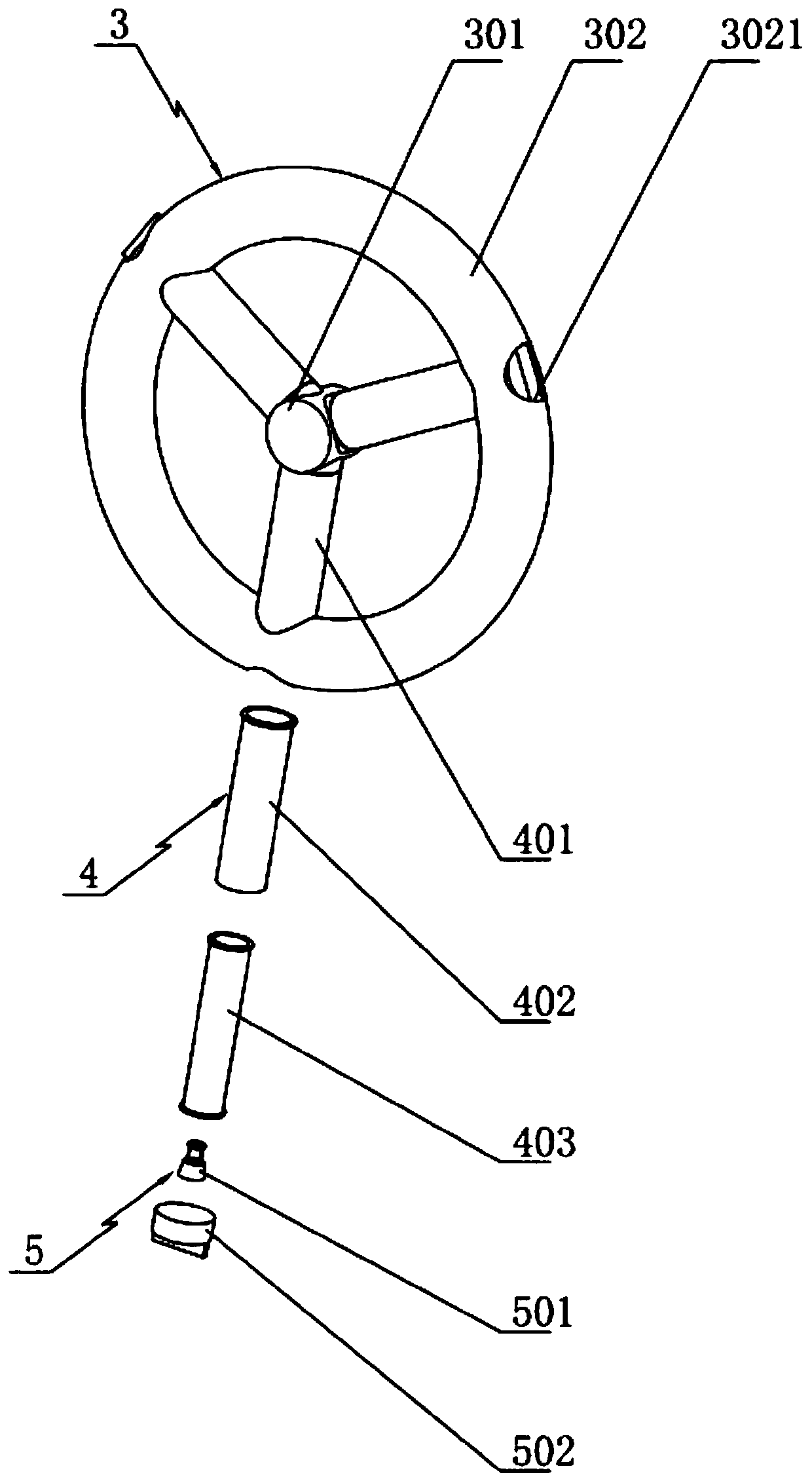

[0035] like Figure 1~3 As shown, the present invention includes a pressure-resistant hatch cover 1, a connecting shaft 2 is installed vertically in the middle of the pressure-resistant hatch cover 1, and a handwheel 3 is installed on the top of the connecting shaft 2, and the handwheel 3 includes a handwheel body 301 and a handwheel ring 302 , the handwheel body 301 is a columnar structure coordinating with the top of the connecting shaft 2, several telescopic assemblies 4 extending outward and passing through the handwheel ring 302 are evenly distributed along the circumference of the handwheel body 301, each telescopic assembly 4 is installed with a control telescopic assembly 4 Extended or shortened snap assembly 5.

[0036] like Figure 4~6 As shown, the structure of a single telescopic assembly 4 is: a tail rod 401 comprising a tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com