Liquid crystal composition and liquid crystal display element

A technology for liquid crystal display elements and liquid crystal compositions, applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of easy change of tilt angle, not easy to change, slow polymerization, etc., and achieve high tilt stability and fast polymerization speed. , the effect of high VHR

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0225] In Example 1 (E-01) to Example 4 (E-04), RM was 0, which was a sufficiently small value below the lower limit of detection. In addition, it was confirmed that Tilt of these was a sufficiently large value, IS was a sufficiently small value, and VHR was a sufficiently high value. From the above, it was confirmed that these Examples solved the problems of the present invention. On the other hand, it was confirmed that the IS of Comparative Example 1 (C-01) was 135, which was very large, and that the RM of Comparative Example 2 (C-02) was 11, which was a large value. From the above, it was confirmed that these comparative examples cannot solve the problems of the present invention.

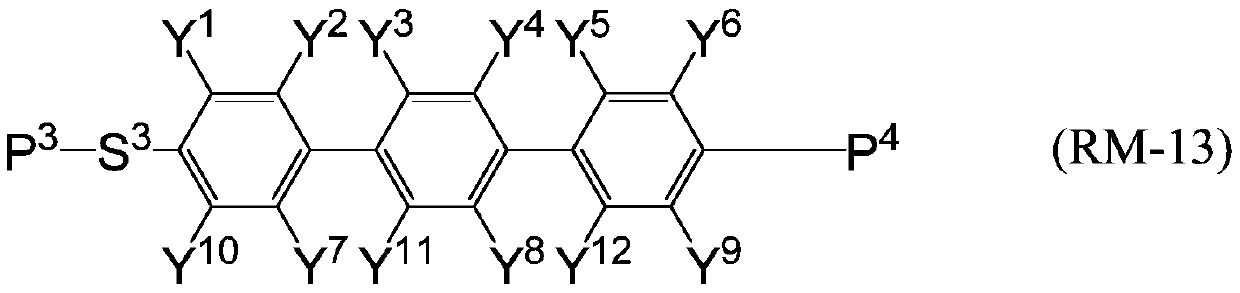

[0226] [chem 25]

[0227]

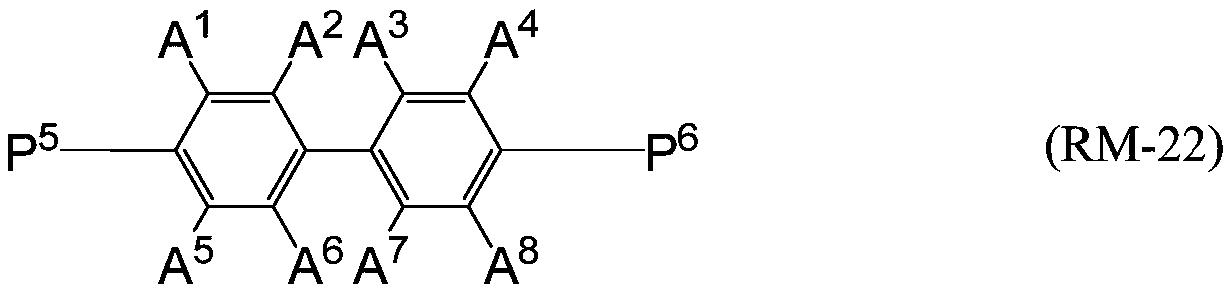

[0228] Prepared by replacing the polymeric compound represented by the formula (RM-22O2) contained in Example 1 (E-01) to Example 4 (E-04) with the polymeric compound represented by the formula (RM-22O1) It was confirmed that the problem of the present invention ...

Embodiment 5

[0240] In Example 5 (E-05) to Example 10 (E-10), RM was 0, which was a sufficiently small value below the detection lower limit. In addition, it was confirmed that Tilt of these was a sufficiently large value, IS was a sufficiently small value, and VHR was a sufficiently high value. From the above, it was confirmed that these Examples solved the problems of the present invention.

[0241] In the examples of the present invention, it was confirmed that the problem of the present invention was solved when about 1% of a compound suitable for PI-free having an OH group as a polar group was added to form a liquid crystal display element from a substrate without an alignment film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com