Atomic layer deposition process control method for corrosive and hazardous gaseous precursors

An atomic layer deposition and process control technology, applied in gaseous chemical plating, coating, metal material coating process, etc., to reduce safety hazards, prolong contact reaction time, and reduce cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

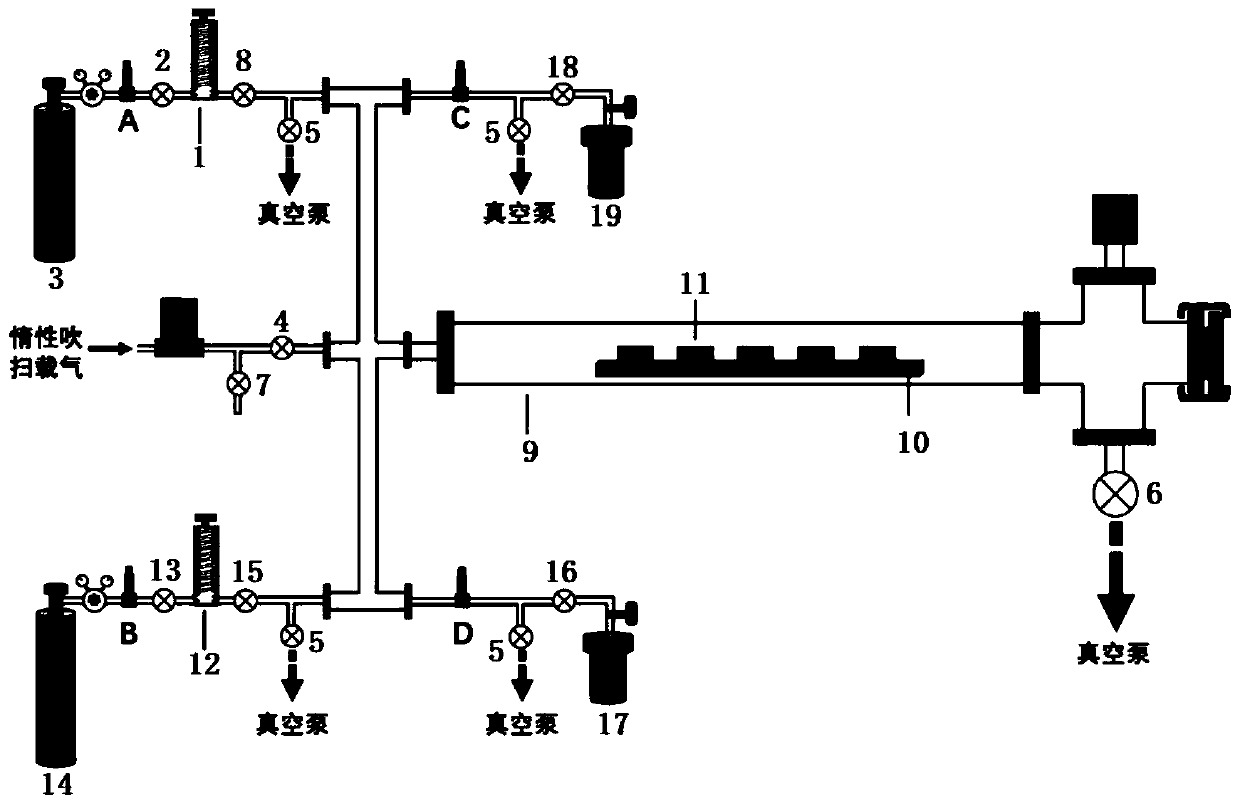

Method used

Image

Examples

Embodiment 1

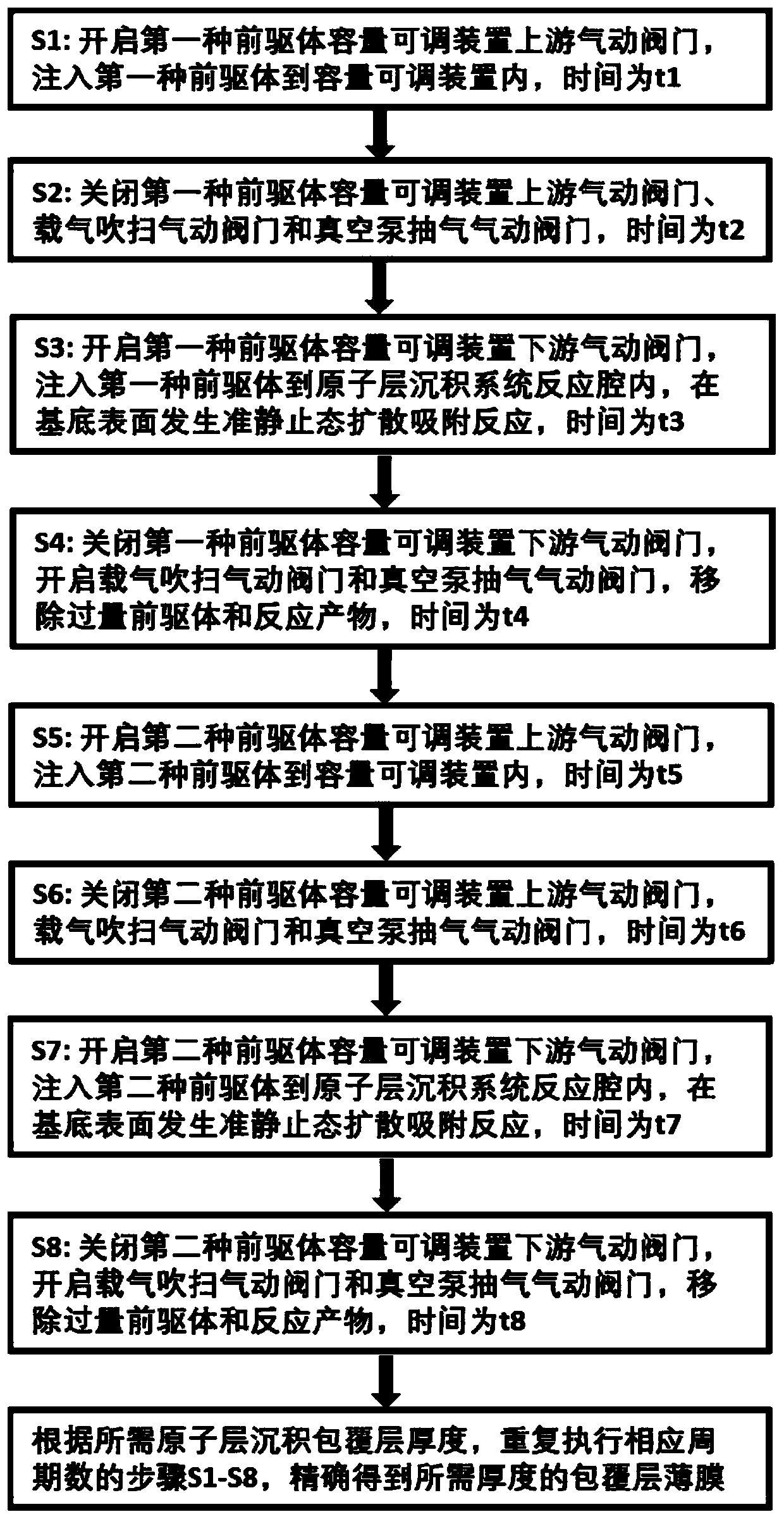

[0046] This example proposes a process control method for atomic layer deposition of corrosive and dangerous gaseous precursors. The prepared film is W, and the two corrosive and dangerous gaseous precursors used are Si respectively. 2 h 6 and WF 6 , the substrate material is a silicon wafer, and the atomic layer deposition temperature is 220°C. Such as image 3 As shown, the method specifically includes the following steps:

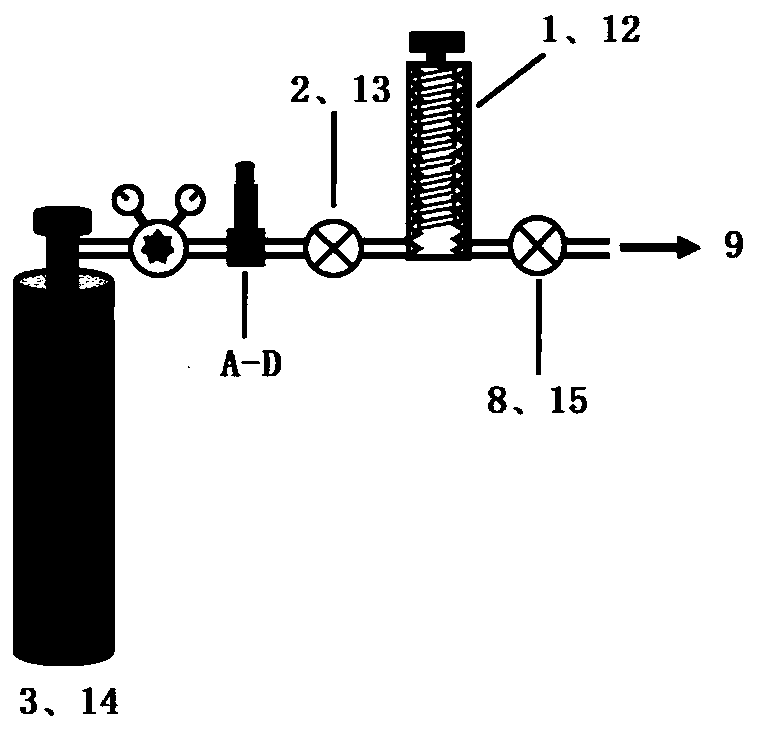

[0047] Step S1: Open the upstream pneumatic valve 2 of the first-type gaseous precursor capacity-adjustable device 1, and inject the first-type gaseous precursor from the first-type precursor storage 3 into the first-type gaseous precursor capacity-adjustable device 1 Si 2 h 6 , the time is t1=2s. Among them, the capacity-adjustable device is a pipeline device that can be precisely regulated for the space volume of a small amount of precursor temporarily stored, and the space volume range of the capacity-adjustable device is 10 -1 cm 3 ~10 3 cm ...

Embodiment 2

[0058] This example proposes a process control method for atomic layer deposition using corrosive and dangerous gaseous precursors to prepare doped films. The prepared doped films are W / Al 2 o 3 , the two corrosive and dangerous gaseous precursors used are WF 6 and Si 2 h 6 , and the other two doping precursors are trimethylaluminum TMA and H 2 O, the base material is a silicon wafer, and the atomic layer deposition temperature is 200°C. Such as Image 6 As shown, the method specifically includes the following steps:

[0059] Step S1: Open the pneumatic valve 16 for injecting the first doped precursor, close the pipeline vacuum pump pumping pneumatic valve 5 in the atomic layer deposition system, and inject the first doped precursor into the ALD reaction chamber 9 from the reservoir 17 of the first doped precursor. A dopant precursor TMA undergoes flow dynamic diffusion adsorption reaction on the surface of the substrate 11 for 5 s.

[0060] Step S2: Close the pneumatic...

Embodiment 3

[0076] This embodiment provides a method for controlling the atomic layer deposition process of a corrosive and dangerous gaseous precursor. The prepared film is GaN, and the two corrosive and dangerous gaseous precursors used are respectively Ga(CH 3 ) 3 and NH 3 , the substrate material is molecular sieve MCM-41, and the atomic layer deposition temperature is 400°C. The method specifically includes the following steps:

[0077] Step S1: Open the upstream pneumatic valve 2 of the first-type gaseous precursor capacity-adjustable device 1, and inject the first-type gaseous precursor from the first-type precursor storage 3 into the first-type gaseous precursor capacity-adjustable device 1 Ga(CH 3 ) 3 , the time is 8s.

[0078] Step S2: Close the upstream pneumatic valve 2 of the first gaseous precursor capacity adjustable device 1, close the pipeline carrier gas purge pneumatic valve 4, pipeline vacuum pump pneumatic valve 5 in the atomic layer deposition system, and ALD rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com