A cast-in-place composite construction method for a thick concrete roof structure system

A technology for a concrete roof and a construction method, which is applied to the dome roof structure, arch structure, building components, etc., can solve the problems that the cast-in-place concrete pouring process is difficult to meet the requirements, the height is high, and the construction plan is infeasible, and the steel bar is achieved. The effect of simple binding, simplified support system and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

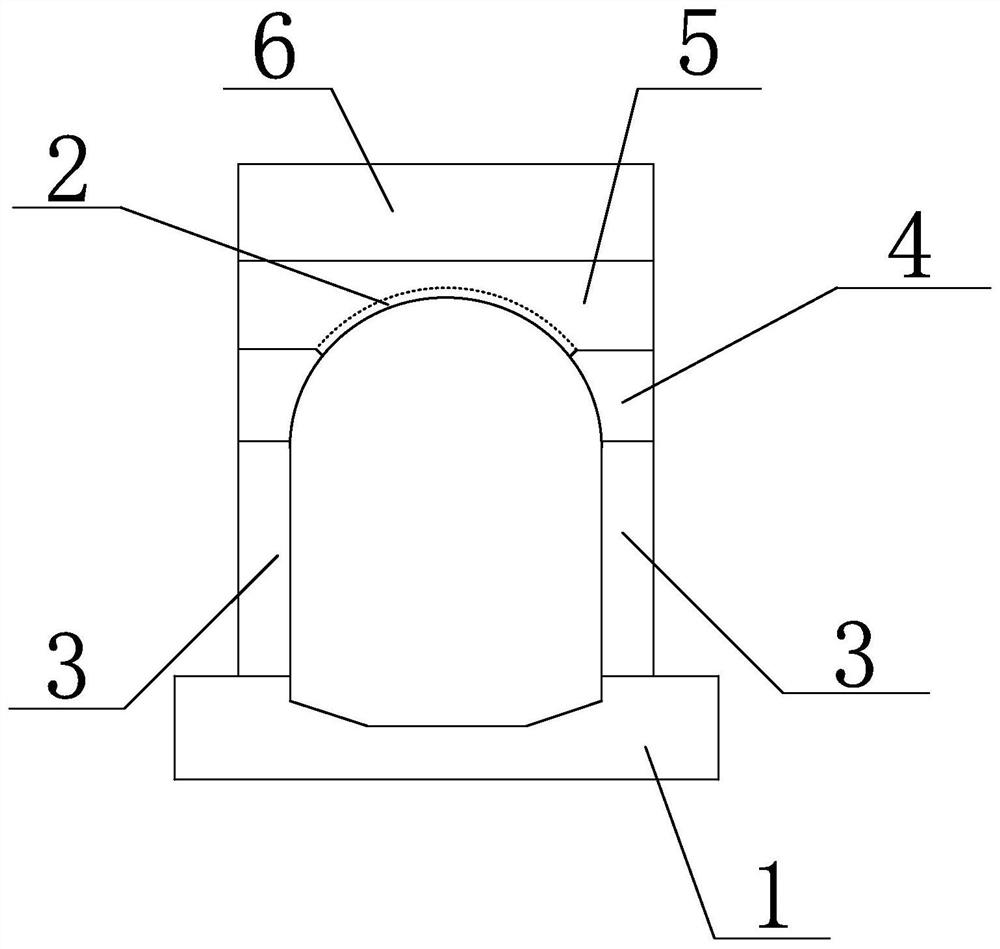

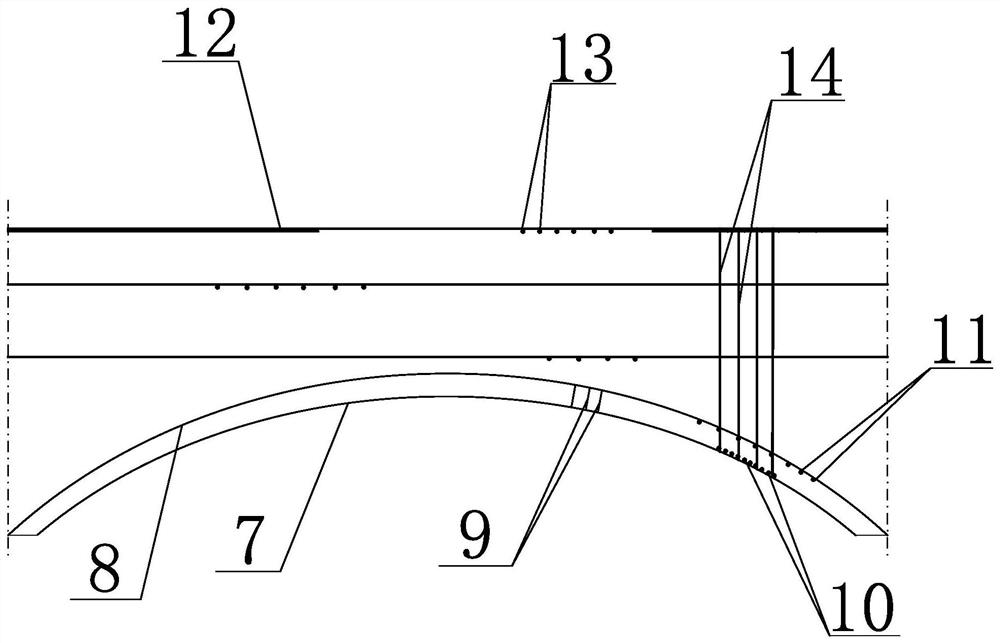

[0026] Such as figure 1 As shown, a kind of cast-in-place superimposed construction method of the heavy concrete roof structural system of the present invention comprises the following steps: 1) adopt concrete to carry out the pouring of base plate 1; After the installation of the steel reinforcement cage is completed, concrete is poured from the bottom to the required height of the side wall 3, and then the pouring is stopped, and the pouring of the side wall 3 is completed; formwork, install arch reinforcement along the surface of the arch formwork, pour concrete, the pouring height is H1, and complete the first node 4 pouring, wherein H1Sag height of the arch formwork, the bottom surface of the hidden arch layer 5 is arched, and the top surface is flat; 5) After the second pouring of the hidden arch layer 5 is completed and the strength is obtained, the hidden arch layer and the dark arch ring are used as supports For the force-bearing system, install flat top layer reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com