Inducer with high cavitation resistance

An inducer and performance technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as it is difficult to greatly increase the C value, and achieve improved resistance Cavitation performance, reduced torsion, effect of low NPSH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

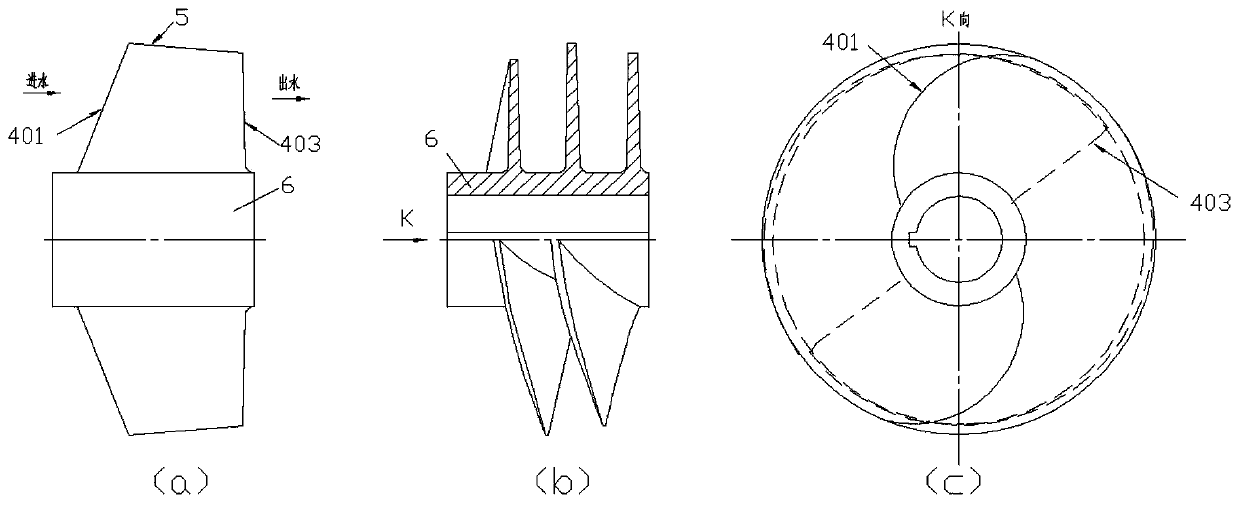

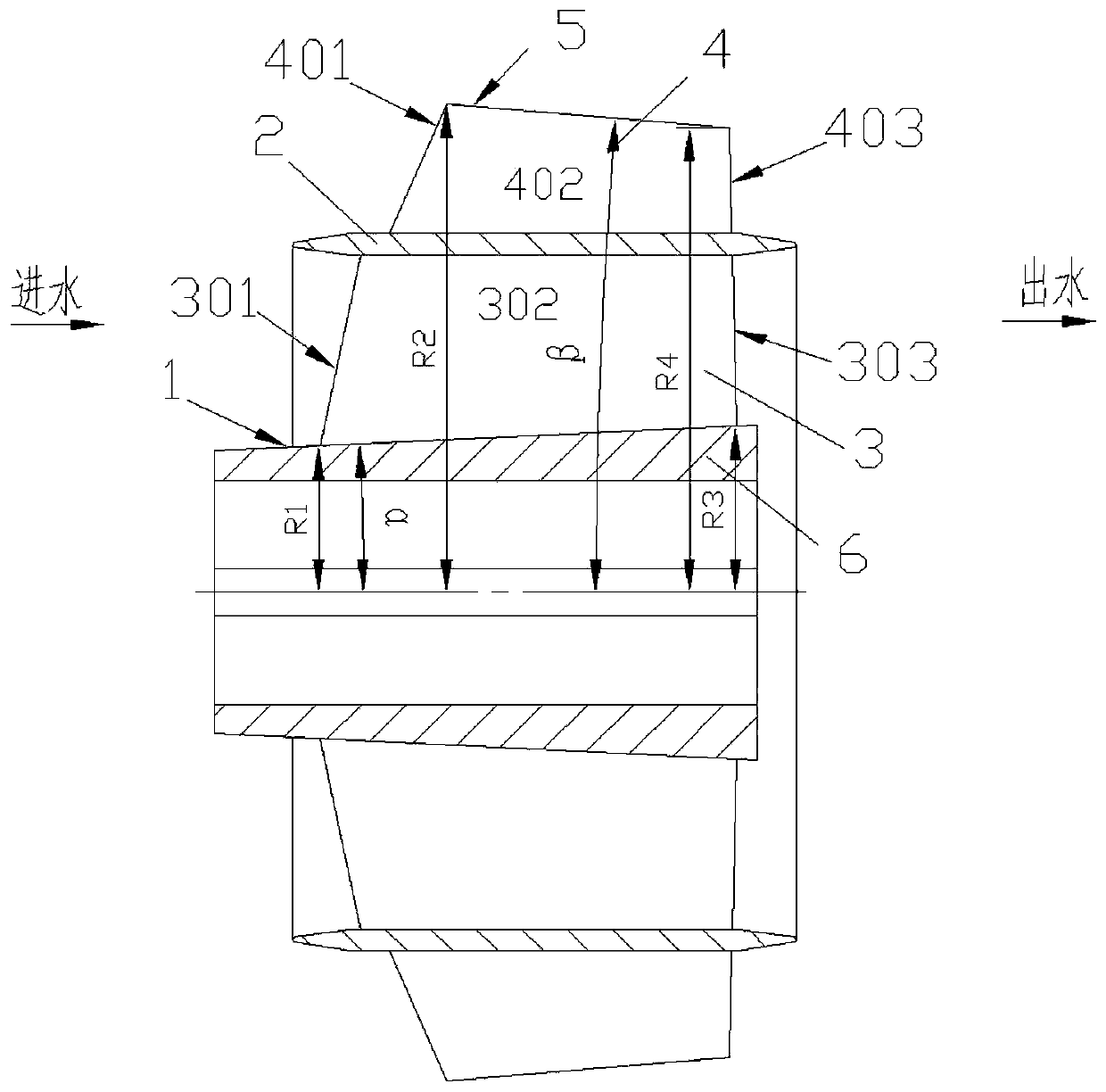

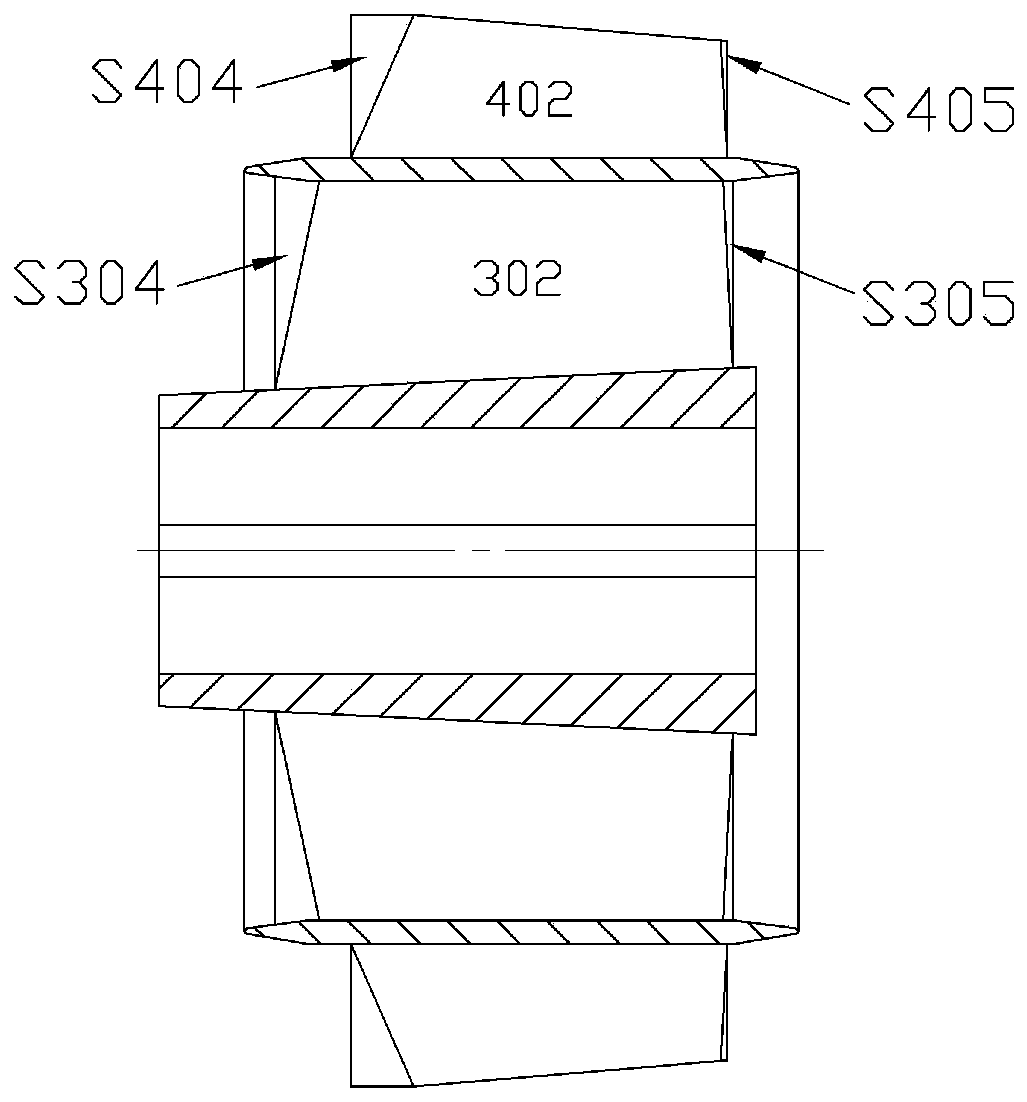

[0042] Embodiment 1 is the inducer of the 2-layer axial flow channel, such as figure 2 , image 3 and Figure 5As shown, in the inducer with high anti-cavitation performance of the present invention, the inducer hub 6 is the central area formed by the hub axial streamline 1 rotating 360° around the inducer axis center line, the inducer The outer side of the wheel hub 6 is provided with an axial surface flow channel A 3 and an axial surface flow channel B 4 which are not connected to each other, and the axial surface flow channel A 3 and the axial surface flow channel B 4 are separated by a flow channel dividing plate A 2 . The axial surface flow channel A3 is the inner axial surface flow channel, the axial surface flow channel B4 is the outer axial surface flow channel, the outer axial surface flow channel is located outside the inducer, and the inner axial surface flow channel is located on the outer axial surface Between the runner and the hub. The included angle α betwe...

Embodiment 2

[0055] Embodiment 2 is the inducer of 3 layers of mutually disconnected axial flow passages, such as Figure 6 As shown, the outer side of the hub 6 of the inducer is provided with an axial surface flow channel A 3, an axial surface flow channel B 4 and an axial surface flow channel C 8, and the axial surface flow channel A 3 and the axial surface flow channel C 8 pass through The channel dividing plate B 9 is isolated, and the axial channel B 4 and the axial channel C 8 are isolated by the channel dividing plate A 2 . The axial surface flow channel A 3 and the axial surface flow channel C 8 are both inner axial surface flow channels, the axial surface flow channel B 4 is the outer axial surface flow channel, the outer axial surface flow channel is located outside the inducer, and the inner shaft surface The surface flow channel is located between the outer axial surface flow channel and the hub. The blade 3 is arranged between the streamline side 1 of the axial surface of th...

Embodiment 3

[0056] Example 3 as Figure 7 As shown, on the basis of Example 1, the outer rim cover plate 7 is added to the outer flow line 5 of the axial flow channel B 4 to prevent leakage of the tip of the blade and further improve the anti-cavitation performance.

[0057] In the actual operation process, the inducer pressurizes the propellant to generate a certain head to increase the inlet pressure, avoid cavitation, and improve cavitation performance. However, during the high-speed operation of the inducer, its operating conditions often change, especially when the internal partial pressure drops below the saturated vapor pressure and cavitation occurs, which will lead to strong cavitation inside the inducer, causing performance Decline, the vibration of the system structure is strengthened, thus affecting the reliability of the entire device system and the service life of the inducer.

[0058] Taking the cavitation process on the blade A 302 as an example, under the condition of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com