Power battery temperature prediction model based on liquid cooling heat dissipation mode and modeling method

A liquid-cooled heat dissipation, predictive model technology, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as the limitation of use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

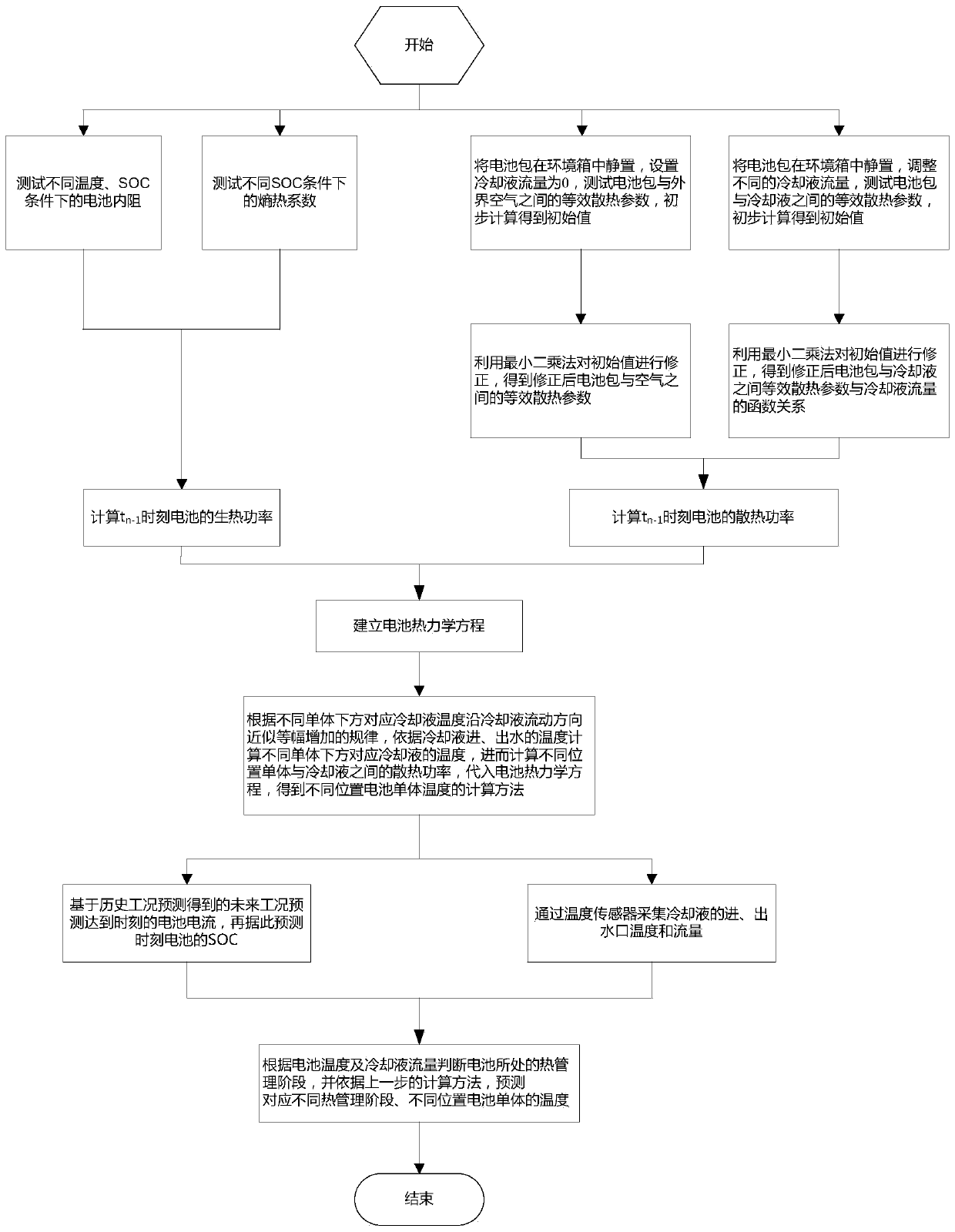

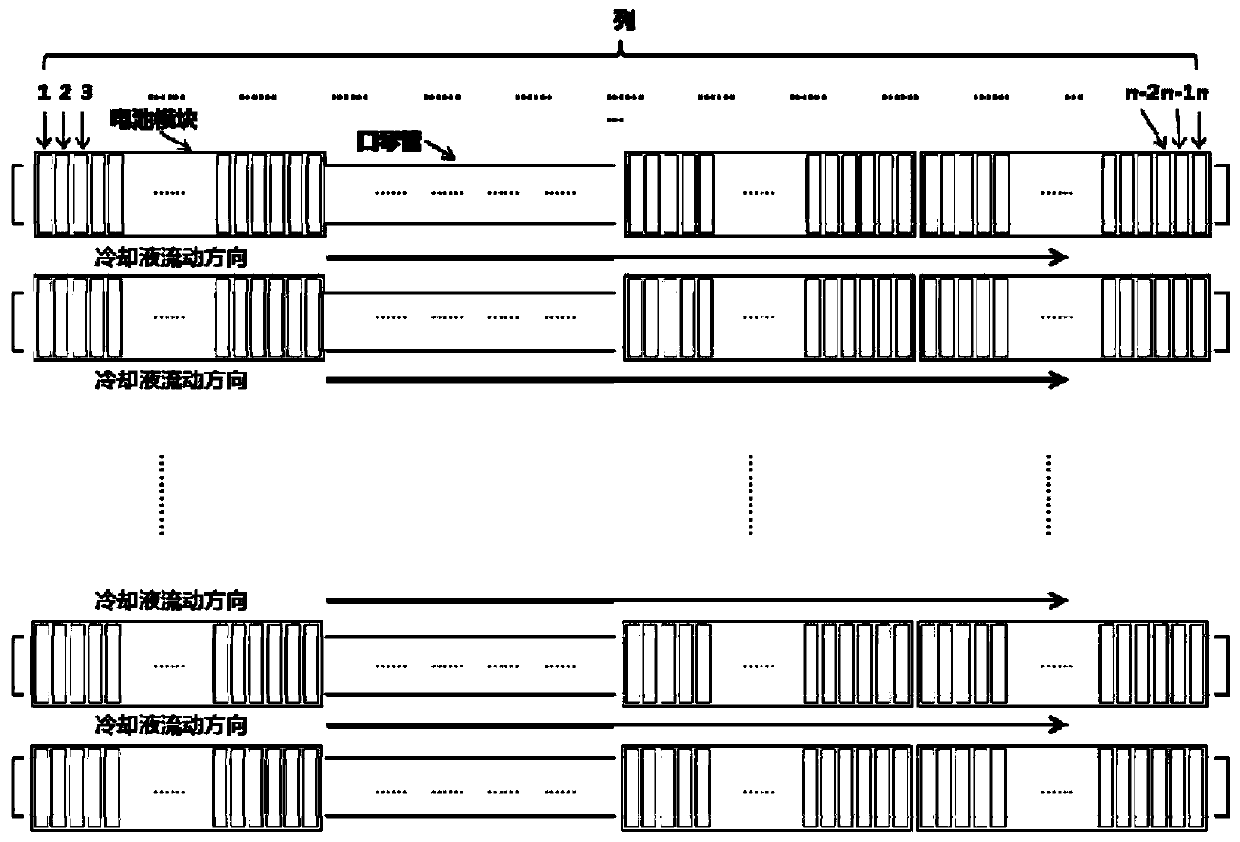

[0151] The present invention provides a power battery temperature prediction model and modeling method based on liquid cooling and heat dissipation. The modeling process is as follows:

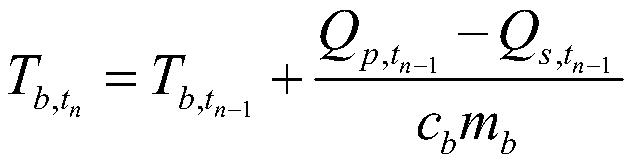

[0152] (1) Establish the thermodynamic equation of the battery:

[0153]

[0154] Among them, c b is the specific heat capacity of the battery, m b is the weight of the battery, and respectively t n and t n-1 the temperature of the coolant at all times, and respectively t n-1 The heat generation power and the total heat dissipation power at any time.

[0155] (2) According to the Bernadi heat generation rate model, the heat generation rate Q of the battery p Can be expressed as follows:

[0156] Q p =I 2 R+IT b k rev

[0157] Among them: R is the internal resistance of the battery; k rev is the entropy heat coefficient of the battery, calculated with the following formula.

[0158]

[0159] Among them, U OCV is the open circuit voltage of the battery.

[0160] Subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com