High-voltage cable laying system and method

A technology for laying high-voltage cables and lines, which is applied in the field of high-voltage cable laying systems. It can solve problems such as large difference in force, easy breakage of high-voltage cables, and damage to high-voltage cables, so as to reduce power and volume, and the laying process is stable. Smooth and smooth laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

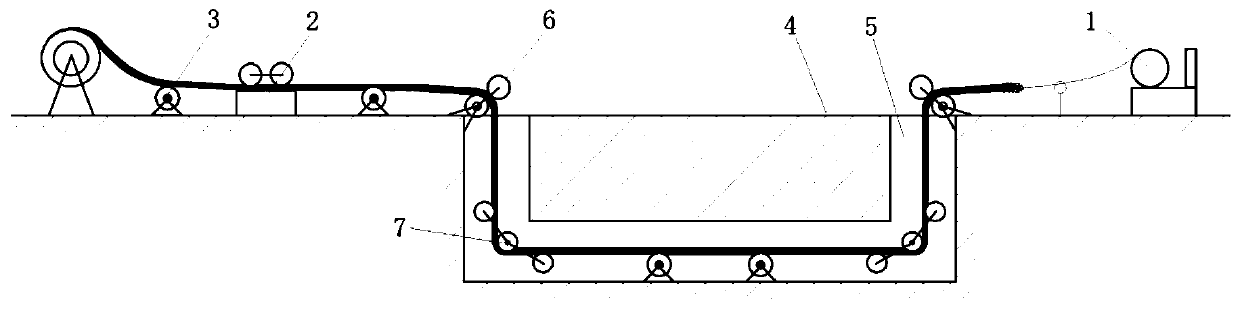

[0028] Such as figure 1 As shown, a high-voltage cable laying system includes: a high-voltage cable tractor 1, a high-voltage cable conveyor 2 and a high-voltage cable drum 3 arranged along the laying line, and a generator for powering the high-voltage cable tractor 1 and the high-voltage cable conveyor 2 And the control device; the motor of the high-voltage cable conveyor 2 is equipped with a PWM governor electrically connected to the control device. Arrange a high-voltage cable conveyor 2 every 50-80m on the high-voltage cable laying line, and arrange a high-voltage cable drum 3 every 5-10m. Within this range, it can be adjusted according to the specific construction environment. The power of the high-voltage cable conveyor 2 is 400W.

[0029] A first servo motor is installed on the high-voltage cable drum 3 as a supplementary power; the first servo motor is electrically connected to the control device through the second PWM governor.

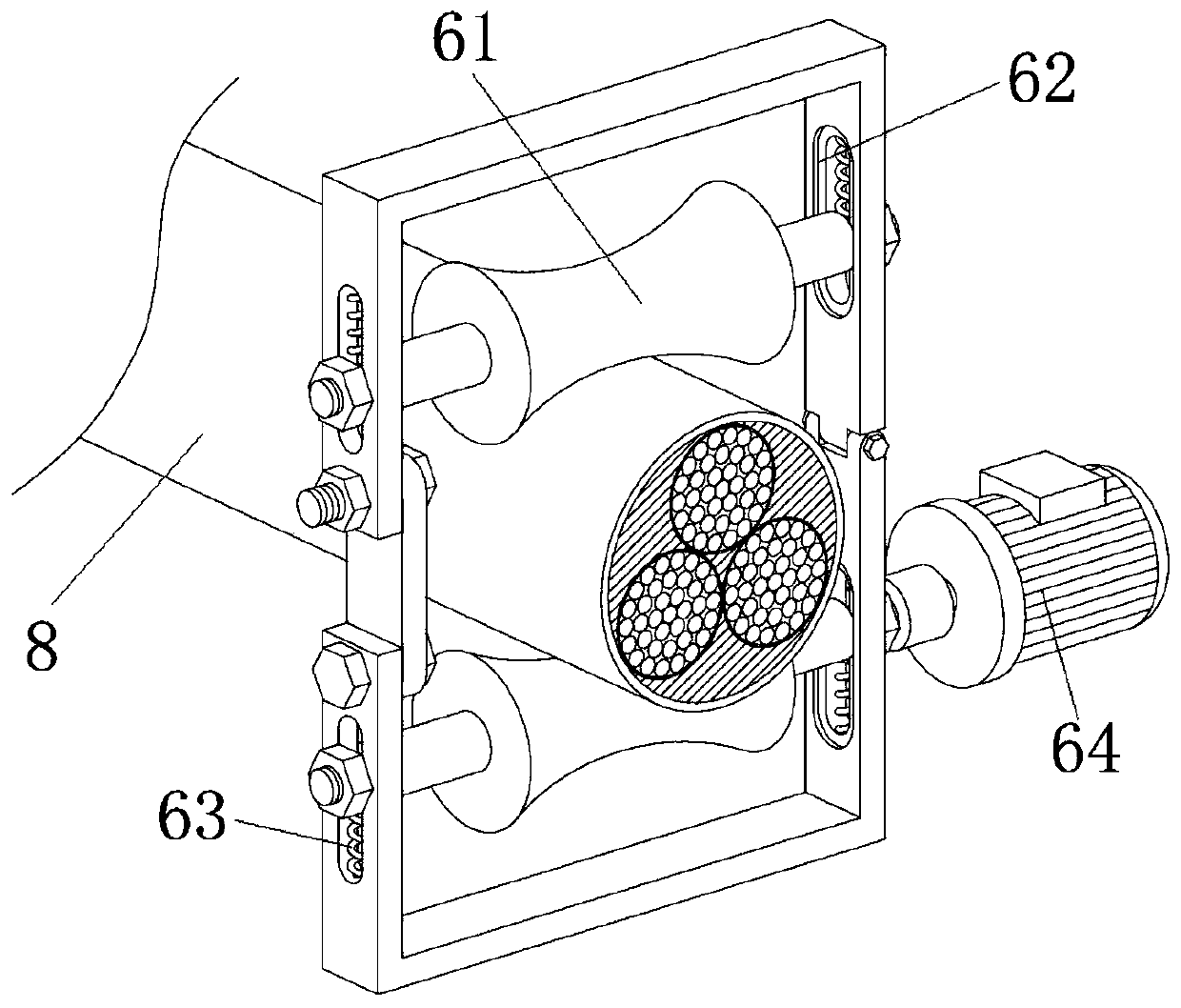

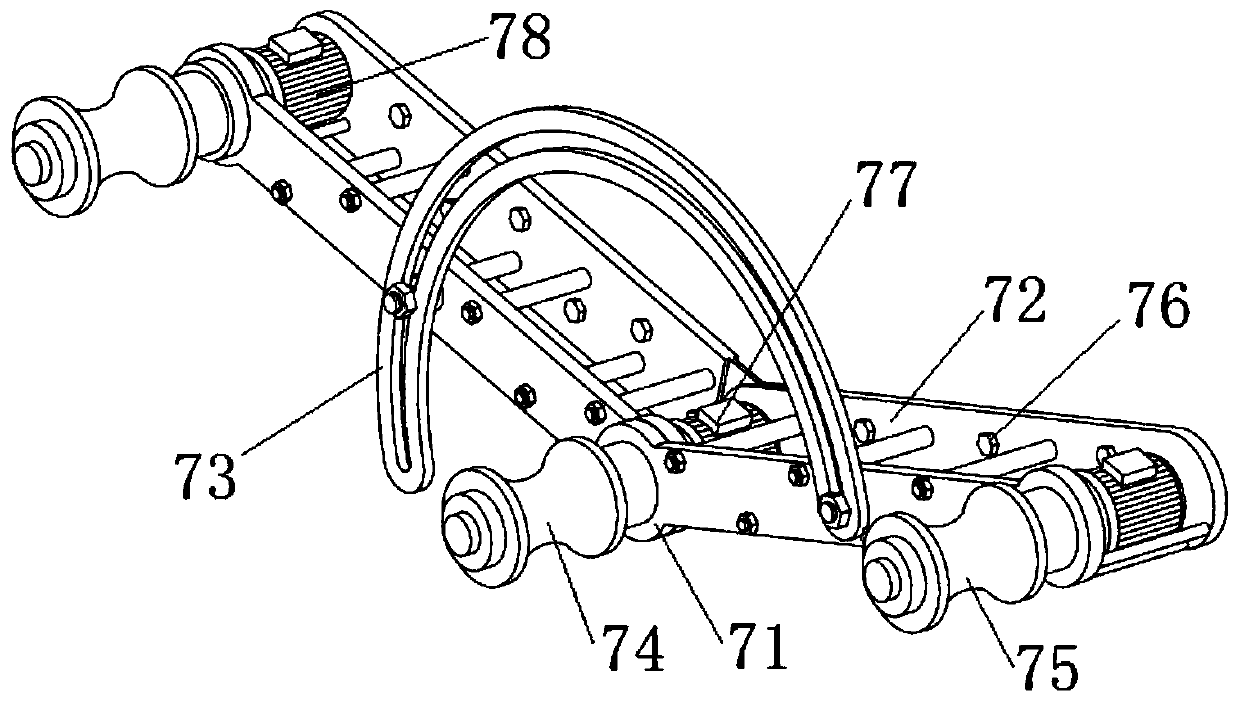

[0030] Such as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com