A floating non-ferrous metal hot roll and processing method

A technology of non-ferrous metals and processing methods, which is applied in the direction of metal processing equipment, metal rolling, metal rolling, etc., can solve the problems of low operation cycle, high roll damage rate, and enterprise cost burden, so as to improve the service life, Effect of increasing strength and reducing floatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

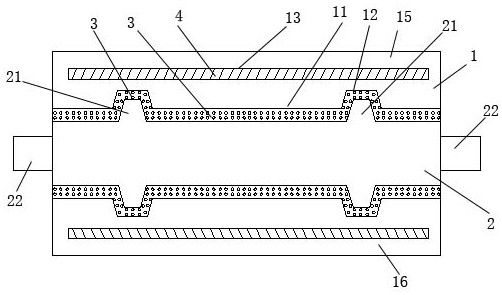

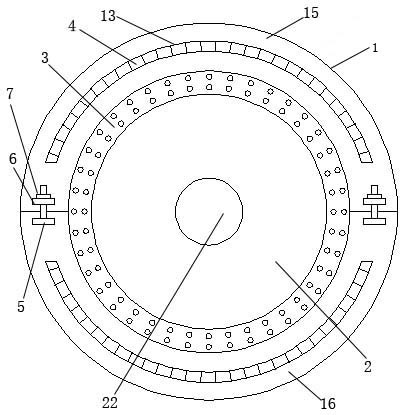

[0024] Such as figure 1 and 2 As shown, a floating non-ferrous metal hot rolling roll includes an outer shell 1 , an inner core 2 , and a floating interlayer 3 . The outer shell 1 has a cylindrical structure; the outer shell 1 is provided with a circular socket cavity 11; the inner core 2 has a cylindrical structure; two ends of the inner core 2 are provided with connecting shafts 22; the upper and lower sides of the circular sleeve cavity 11 of the outer shell 1 are respectively provided with limiting grooves 12; the upper and lower sides of the inner core 2 are respectively provided with positioning teeth 21; the outer shell 1 passes through the circle The socket cavity 11 is socketed on the outside of the inner core 2; the inner core 2 and the outer shell 1 are coaxially arranged; the positioning teeth 21 of the inner core 2 are inserted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com