Strings for changing the direction of fluid flow

A pipe string and fluid technology, applied in the field of pipe strings that change the flow direction of the fluid, can solve the problems of large leakage, easy to occur complex situations, adverse effects, etc., and achieve the effect of solving lost circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

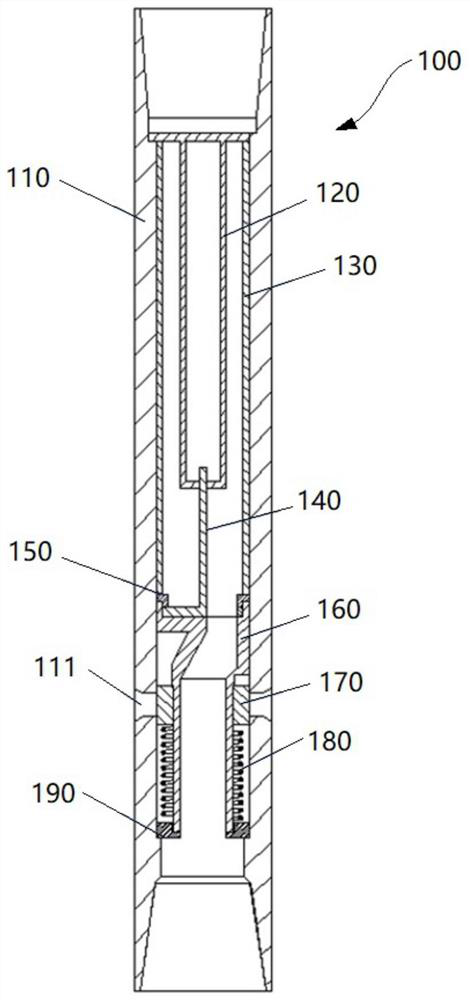

[0028] figure 1 A cross-sectional view of a tubing string 100 according to an embodiment of the invention is schematically shown. Such as figure 1 As shown, the tubing string 100 includes a generally cylindrical outer barrel 110 capable of communicating with upstream and downstream tubing strings such that the tubing string 100 forms part of an overall drilling tool.

[0029] A reversing cylinder 160 is sheathed in the pipe string 100 , and the reversing cylinder 160 forms two channels separated from each other, namely, a first flow channel and a second flow channel. The first flow passage communicates from the upper end of the reversing cylinder 160 to the lower end of the reversing cylinder 160, leading to the downstream pipe string. The second flow channel leads from the upper end of the reversing cylinder 160 to the annular space outside the pipe string 100 (ie, outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com