Friction nano-generator

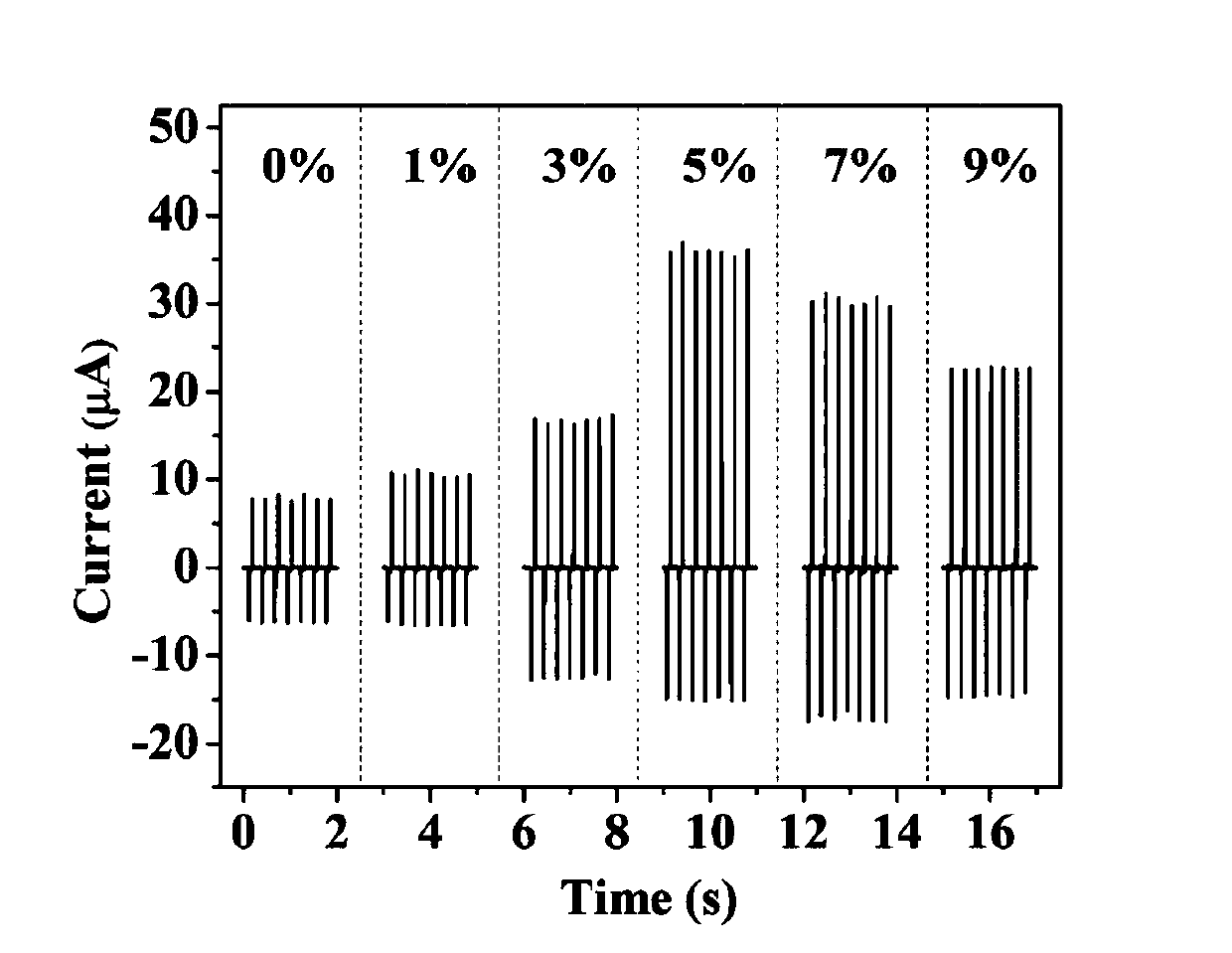

A nanogenerator, friction layer technology, applied in the direction of triboelectric generator, can solve the problems of charge transfer, dissipation, affecting TENG, etc., to achieve the effect of improving output performance and widening the scope of practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

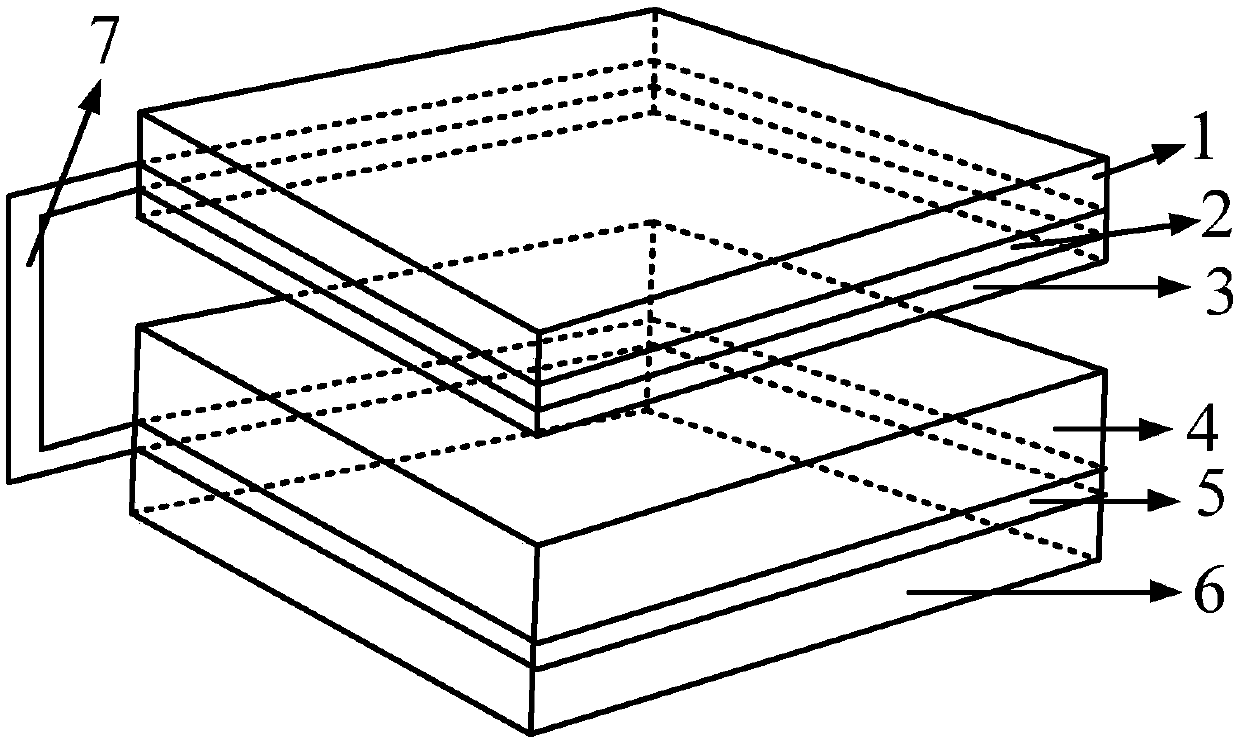

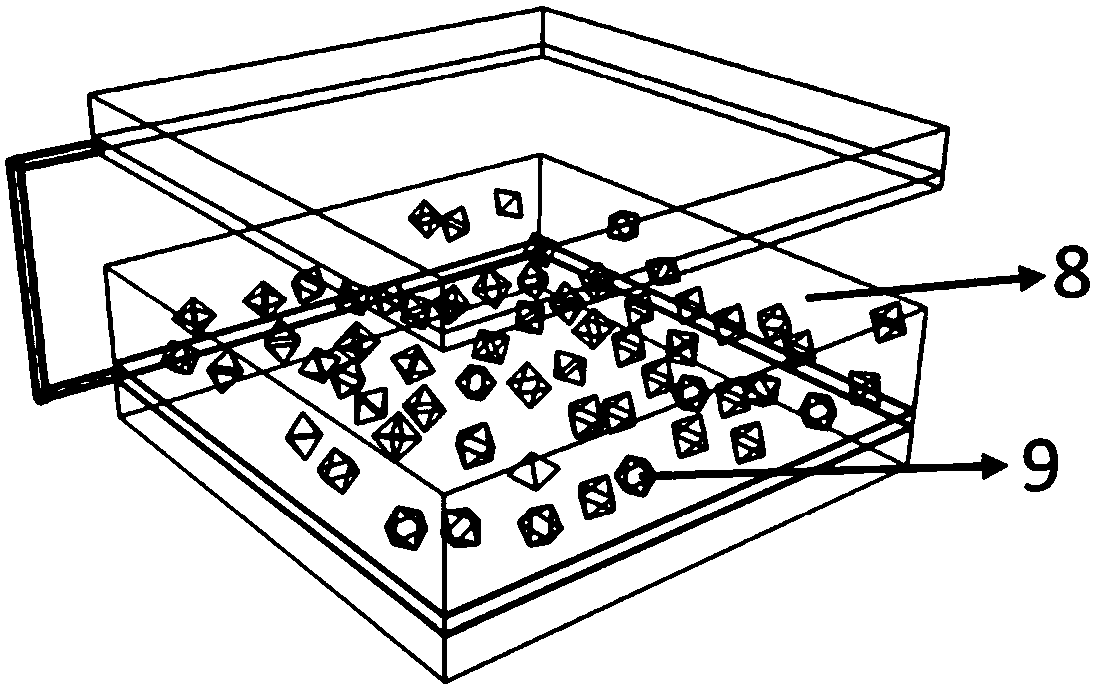

[0039] TENG is a nanogenerator based on triboelectrification and electrostatic induction coupling. Its basic principle is: when an external force is applied, two friction materials rub against each other, charge transfer occurs, and triboelectric charges are generated; after the deformation force is released, the two surfaces automatically Separated, due to the inclusion of an air layer in the middle, the charges on the two surfaces cannot be completely neutralized, thus forming a potential difference; in order to balance the potential difference, the opposite electric charge is induced on the electrode plate, and the external circuit will form an instantaneous current; when the external force is applied again, The potenti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com