An automatic stamping system

An automatic, stamping head technology, applied in the direction of safety equipment, feeding devices, manufacturing tools, etc., can solve the problems of low stamping efficiency, high production cost, injury, etc., to achieve improved stamping efficiency, low production cost, and increased danger Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

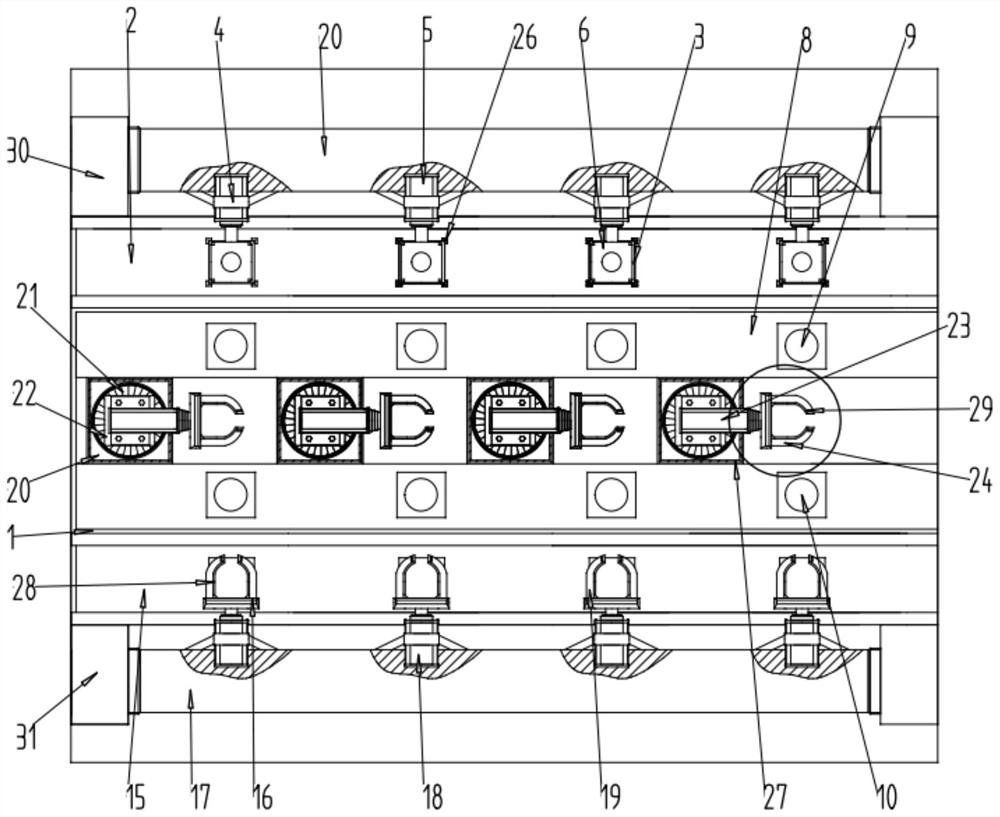

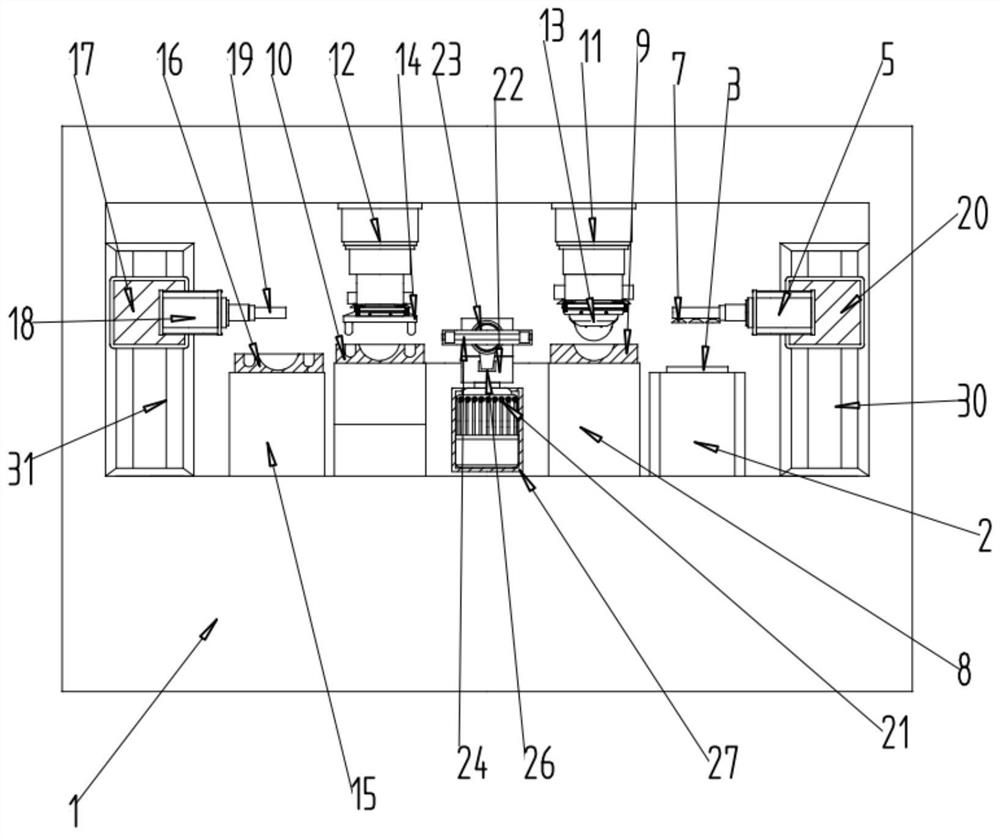

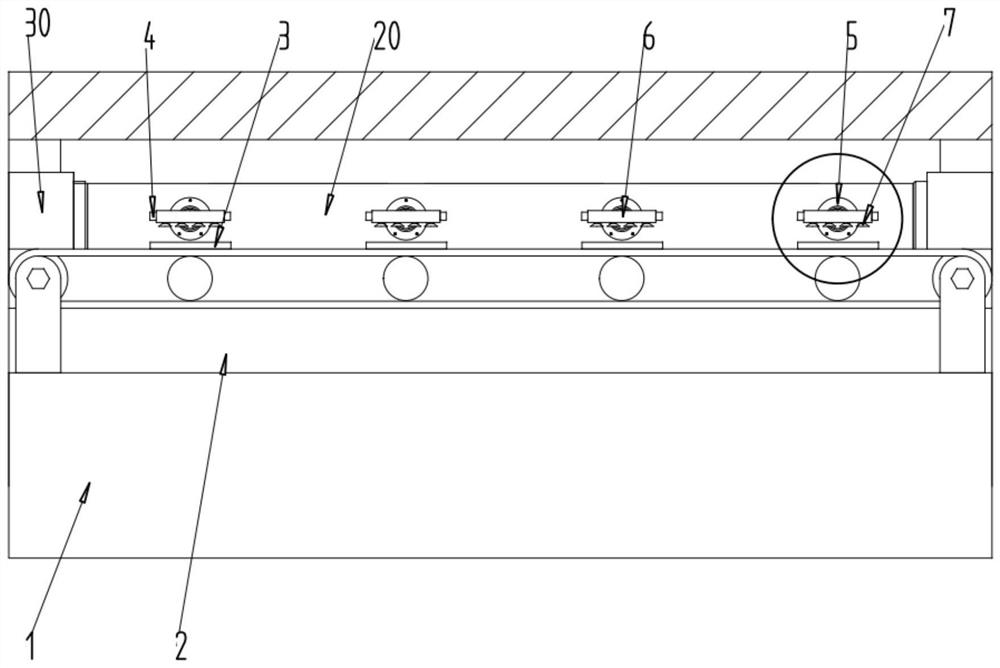

[0031] Embodiment: an automatic stamping system, comprising a body 1, on which a feeding structure, a stamping structure and a discharging structure are installed;

[0032] Please refer to the attached Figure 1-7 , in the specific implementation process, the feeding structure includes: the first conveyor 2, several fixed seats 3, two first linear module translation platforms 30, the first carrying plate 20, several first cylinders 5, Several connecting plates 6 and several vacuum suction cups 7; the connection relationship is as follows:

[0033] The first conveyor 2 is placed on the machine body 1, several fixed seats 3 are respectively placed on the first conveyor 2, two first linear module translation platforms 30 are respectively placed at both ends of the machine body 1, and the first bearing plate The two ends of 20 are respectively connected to the moving ends of the two first linear module translation stages 30, several first cylinders 5 are respectively arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com