Packaging structure for washing machine

A packaging structure, washing machine technology, applied in the directions of packaging, packaging food, machine containers, etc., can solve the problems of damage to the overall shape of the washing machine, injury to the body or personnel, washing machine falling off, etc., to reduce indentation damage, shorten installation time, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

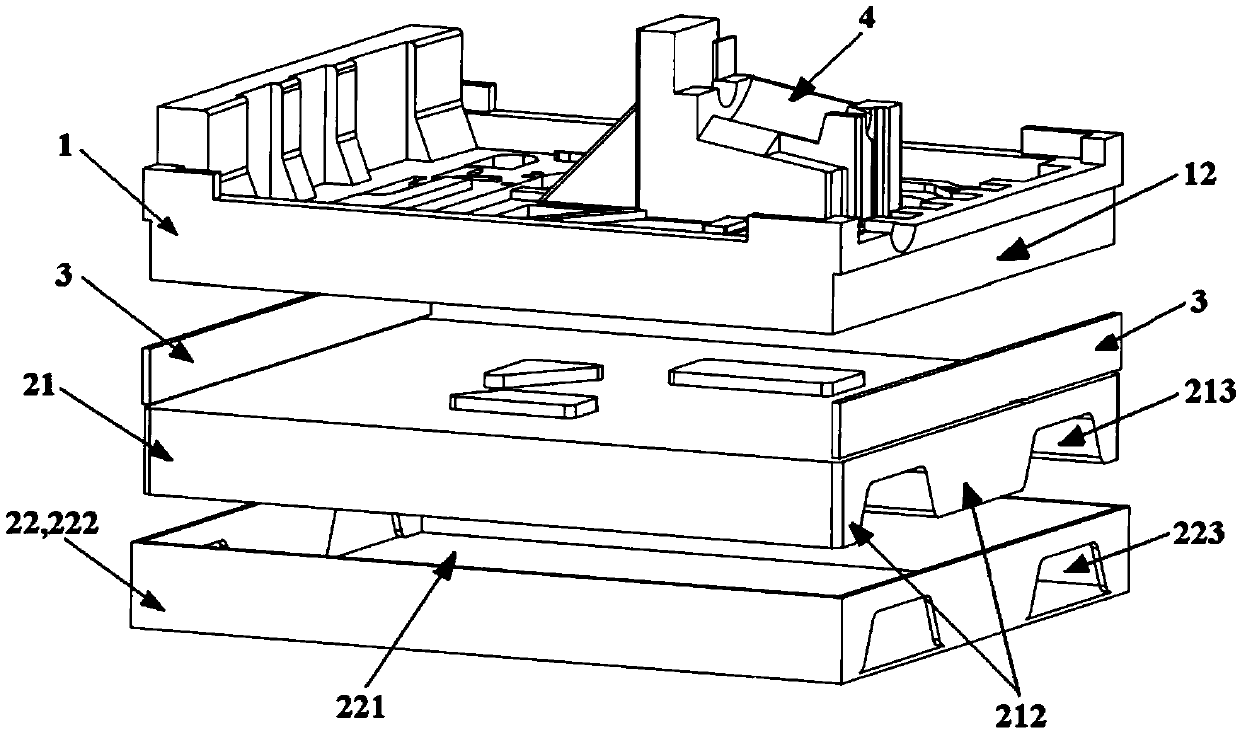

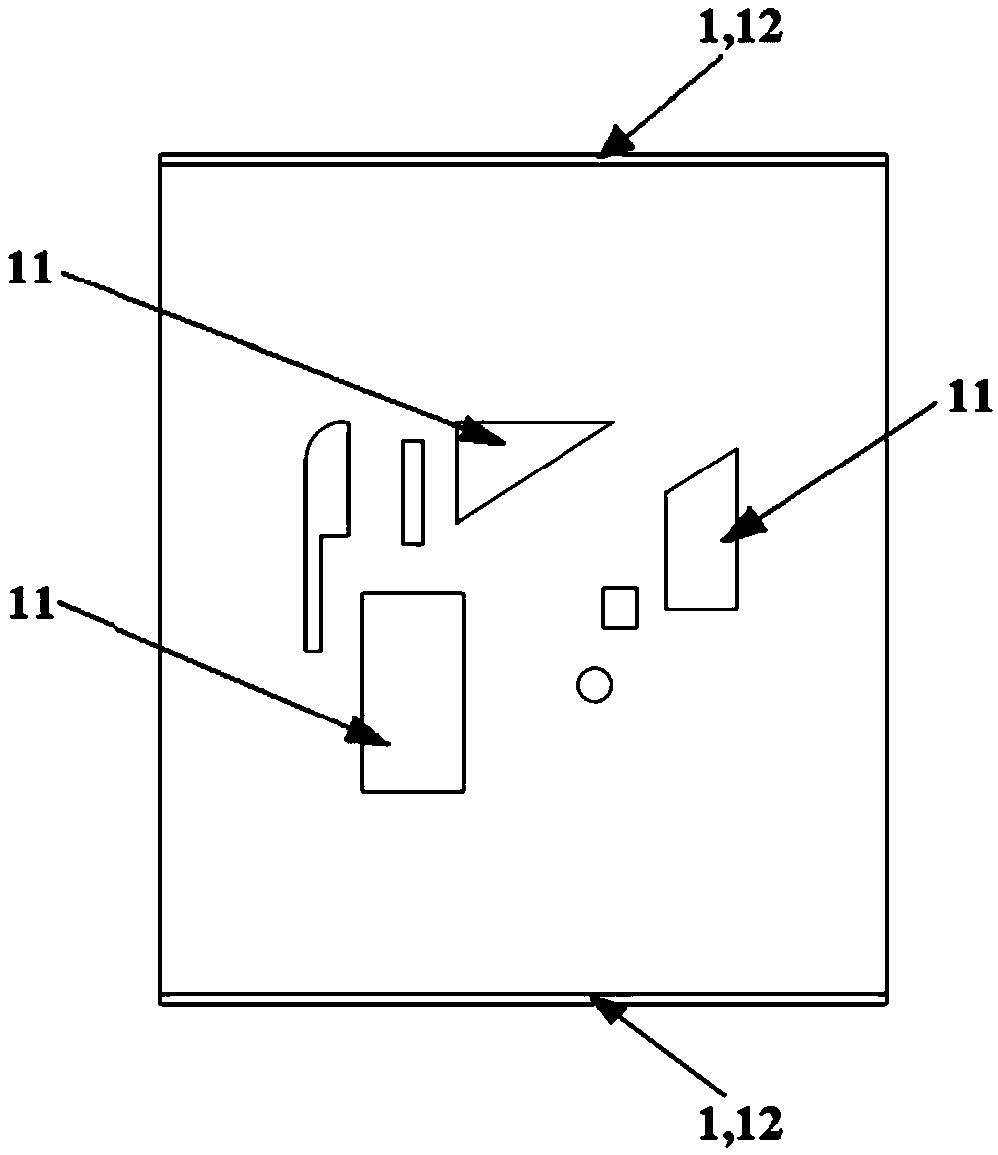

[0042] In this example, if Figure 1~4 As shown, a packaging structure for a washing machine is provided. The packaging structure includes a packaging base 1 located on the upper layer and a packaging base 2 located on the lower layer. The top surface of the packaging base 2 is provided with several bosses 211, so that The boss 211 corresponds to the groove 11 provided on the bottom surface of the packaging base 1, so that the packaging base 1 matched with the bottom of the washing machine and the packaging base 2 for forklift handling are inserted and arranged.

[0043] In this embodiment, the packaging structure adopted has a multi-layer composite structure, the upper layer directly contacts with the bottom of the washing machine is the packaging bottom liner 1 made of soft material, the soft material can be foamed plastics or similar materials, and The packaging base 2 that is arranged close to the bottom surface of the packaging base 1 adopts a combination of soft and hard...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is:

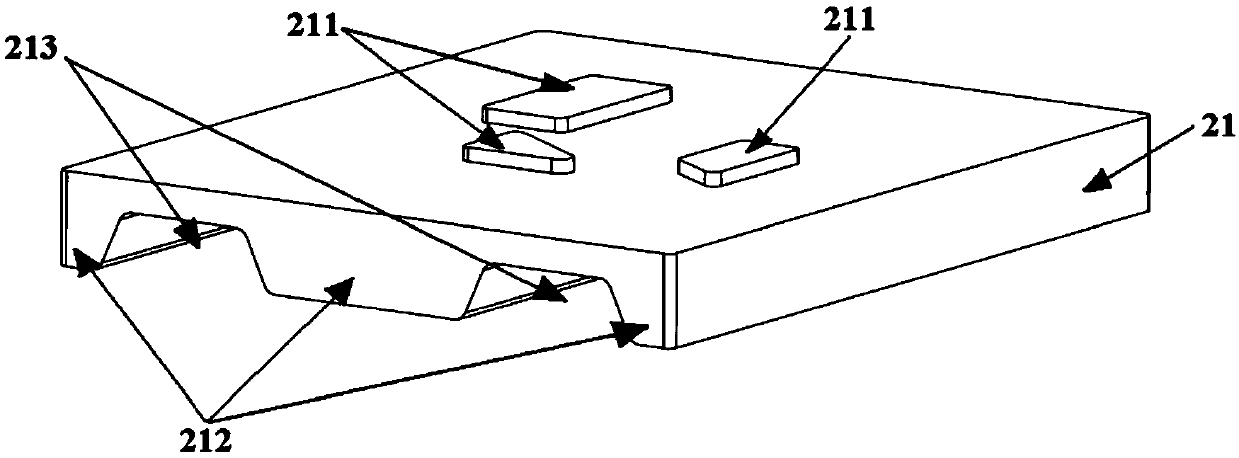

[0061] In this embodiment, the bottom surface of the packaging base 2 is integrally formed with several feet 212, and the adjacent feet 212 are equidistantly arranged, so that the gap between the feet 212 forms a forklift groove 213; the center of the bottom surface of the packaging base 2 is provided with a The feet 212 are provided with three feet 212 evenly along each side of the packaging base 2 , and the adjacent two sides share the feet 212 at the corners, so that the fork can be inserted from each side of the packaging base 2 .

[0062] In this embodiment, the bottom surface of the packaging base 2 is provided with several feet 212, and the bottom feet 212 extend downward from the bottom surface of the packaging base 2, so that a forklift for the fork of a forklift is formed between each foot 212. Groove 213, according to actual use demand, select the forklift groove 213 design that can stretch into pa...

Embodiment 3

[0067] The difference between this embodiment and embodiment 2 is:

[0068] In this embodiment, the depth of the partial depression on the top surface of the packaging base 1 is equal to the thickness of the packaging base 1, so that the depression penetrates the packaging base 1 to form a through hole, and the boss 211 provided on the packaging base 2 passes through the through hole and automatically The top surface of the packaging bottom liner 1 protrudes upwards, and the top of the boss 211 is provided with a protective liner 4 that matches the inner drum motor of the washing machine to limit the relative movement between the inner drum motor of the washing machine and the packaging base 2 .

[0069] In this embodiment, the protrusion corresponding to the opening of the motor at the bottom of the washing machine can be a boss 211, the boss of the packaging base 2 is extended to pass through the through hole as the groove 11 in the packaging bottom liner 1, and a The protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com