Electrochemistry-based alkaline waste residue dealkalization method

An electrochemical and alkaline technology, applied in the electrolysis process, electrolysis components, solid waste removal, etc., can solve the problems of difficult recovery of sodium and alkali, failure to meet the requirements of alkali content of red mud raw materials for building materials, high energy consumption, etc., and achieve technological Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material is Bayer process red mud from an alumina plant in Shanxi, the main content of each component is Na 2 O 8.44%, SiO 2 16.97%, Al 2 O 3 24.15%, CaO 6.32%, Fe 2 O 3 16.97%.

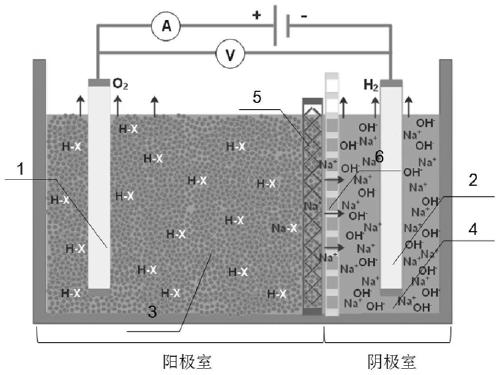

[0040] Mix 1kg of red mud, 5kg of water and 0.6kg of CaO evenly, leaching at 70°C and 200r / min stirring speed for 2h, and then place it in the anode chamber of the electrolytic cell (such as figure 1 ), electrolyzed in the red mud leaching solution at 50 °C, and controlled the initial current density to 500 mA / cm 2 , the electrolysis time is 2h. The red mud in the anode chamber after the reaction is taken out and filtered to complete the separation of the slag phase and the liquid phase, and the slag phase Na after dealkalization 2 The O content was 0.6%, and the pH of the treated alkaline waste was 8.1.

Embodiment 2

[0042] The raw material is Bayer process red mud from an alumina plant in Shanxi, the main content of each component is Na 2 O 8.44%, SiO 2 16.97%, Al 2 O 3 24.15%, CaO 6.32%, Fe 2 O 3 16.97%.

[0043] Mix 1kg of red mud and 5kg of water evenly, leaching for 0.5h in a homogeneous reactor at 90°C, and then place it in the anode chamber of the electrolytic cell (such as figure 1 ), electrolyzed in the red mud leaching solution at 70 °C, and controlled the initial current density to 300 mA / cm 2 , the electrolysis time is 2h. The red mud in the anode chamber after the reaction is taken out and filtered to complete the separation of the slag phase and the liquid phase, and the slag phase Na after dealkalization 2 The O content was 1.5%, and the pH of the treated alkaline waste was 8.5.

Embodiment 3

[0045] The raw material is Bayer process red mud from an alumina plant in Henan, the main content of each component is Na 2 O 6.0%, SiO 2 21.30%, Al 2 O 3 22.20%, CaO 11.43%, Fe 2 O 3 13.97%.

[0046] 1kg red mud, 5kg water and 0.6kg CaCl 2 Mix evenly, leaching for 2 hours at 70°C and 200r / min stirring speed, and then place it in the anode chamber of the electrolytic cell (such as figure 1 ), electrolyzed in the red mud leaching solution at 50 °C, and controlled the initial current density to 800 mA / cm 2 , the electrolysis time is 1.5h. The red mud in the anode chamber after the reaction is taken out and filtered to complete the separation of the slag phase and the liquid phase, and the slag phase Na after dealkalization 2 The O content was 0.5%, and the pH of the treated alkaline waste was 7.9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com