Vacuum rotating assisting device with fan-shaped iron handles

A fan-shaped, iron handle technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of large energy consumption of the prime mover, the kinetic energy of the prime mover cannot be increased, and the kinetic energy of the prime mover cannot be increased. problem, to achieve the effect of improving kinetic energy, saving energy consumption and increasing mechanical energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

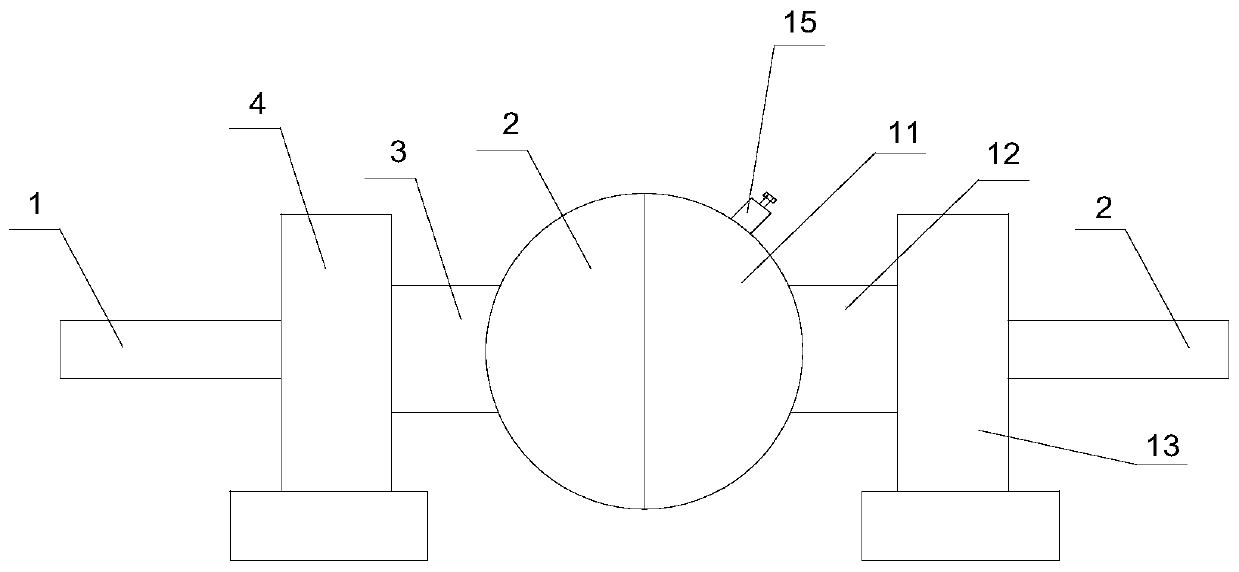

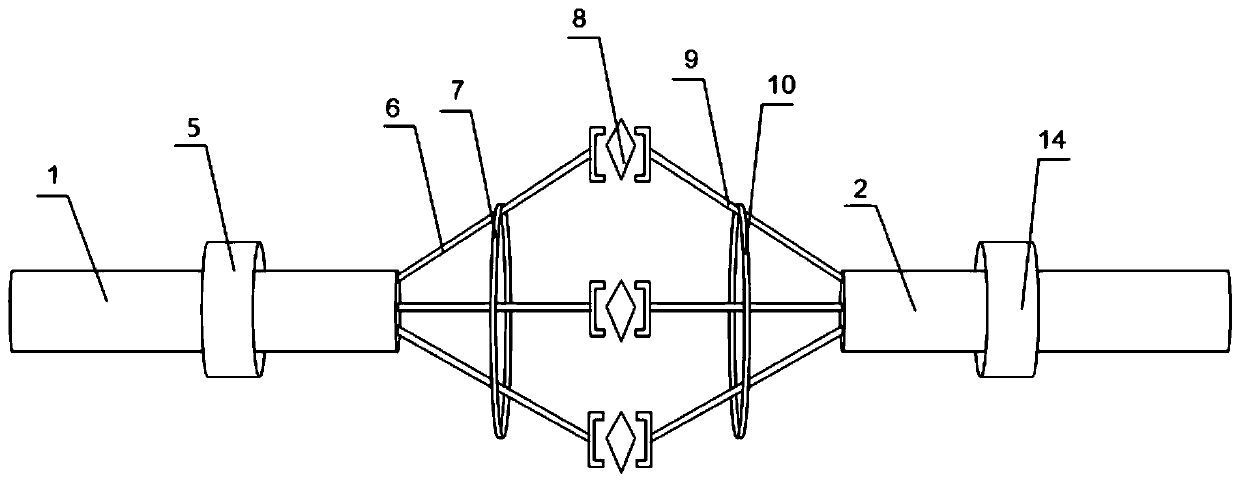

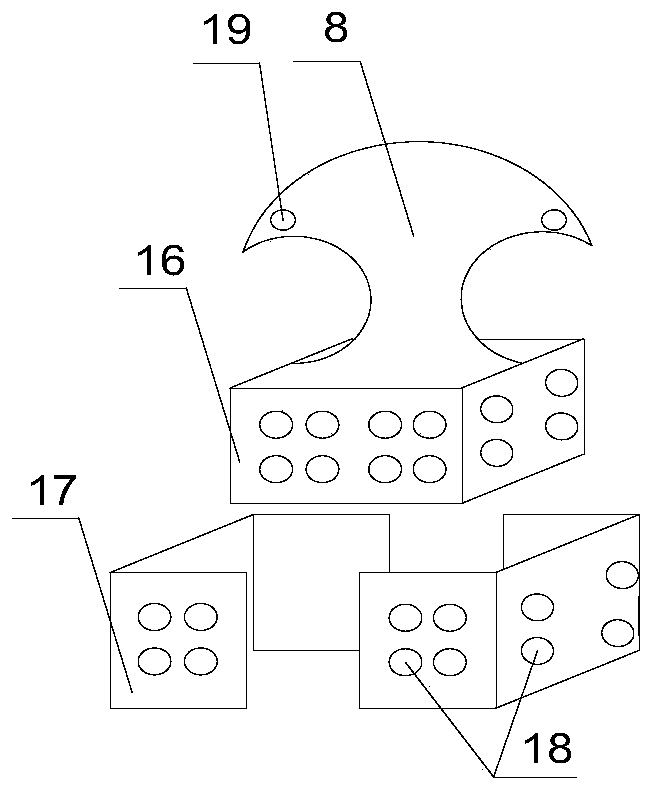

[0031] Such as Figure 1-5 As shown, a vacuum fan-shaped iron handle rotation assisting device of the present invention includes a power input shaft 1 and a power output shaft 2, the outer end of the power input shaft 1 is connected with the prime mover output shaft, and the inner end of the power input shaft 1 is sleeved with The first hemispherical cover 2, the convex surface of the first hemispherical cover 2 is equipped with the first shaft sleeve 3 for power input shaft 1 to insert, one end of the first shaft sleeve 3 communicates with the first hemispherical cover 2, the first shaft sleeve 3 The other end communicates with the first bearing seat 4, the power input shaft 1 is connected with the first bearing seat 4 through the first bearing 5 with a seal, and the power input shaft 1 is installed at least Three first spokes 6 that are singular in number, the inner side of the power input shaft 1 is equipped with a first annular ring 7 coaxial with it, and all the first spo...

Embodiment 2

[0036] Based on Example 1, the surface layer and the inner layer of the first hemispherical cover 2 and the second hemispherical cover 11 are all coated with a heat insulating layer. The heat insulation layer is used to prevent the system from being heated and causing air resistance to affect the normal operation of the system. The heat insulation layer can use glass fiber, asbestos, rock wool, silicate, airgel felt, vacuum board, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com