A kind of railway vehicle fault detection method

A technology for fault detection and rail vehicles, applied in the field of abnormal detection of rail vehicles, can solve the problems of vehicle history data input time step, weak data processing ability, small application range, etc., to ensure accuracy and engineering practicability, and improve Prediction accuracy, effect of simplified models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In the process of detecting temperature-related faults such as axle temperature, bearing temperature, and brake disc temperature, the second step adopts the following specific steps. For the sake of brevity, the present invention focuses on bearings, and describes the whole process from sensor data processing to abnormal temperature diagnosis for a single component to be detected.

[0071] Step 1 is specifically implemented as follows:

[0072] Step 1.1: During the vehicle operation process, obtain the historical data collected by the rail vehicle sensors, and preprocess the above data by downsampling, removing null values, and filling missing values.

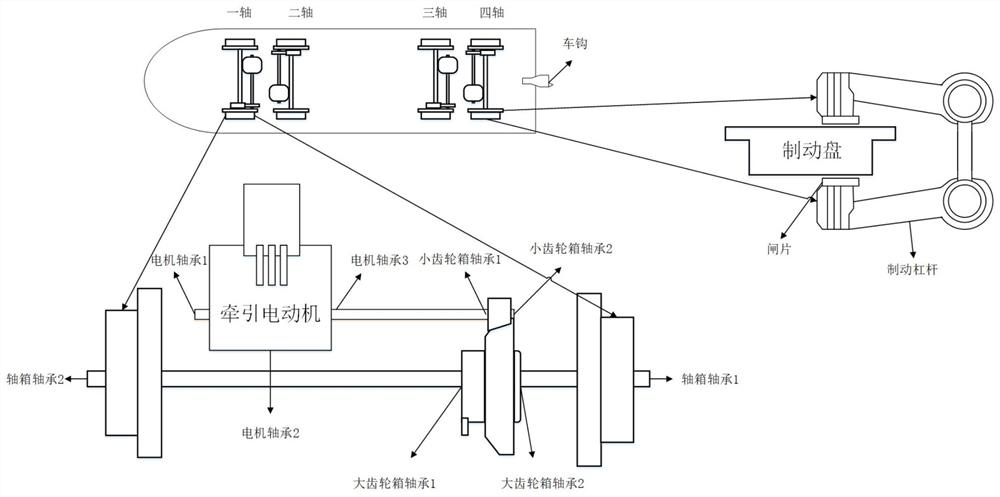

[0073] Step 1.2: Construct a lightweight gradient lifting machine model, with the bearing temperature measurement point as the prediction target, such as figure 1 It shows the distribution position of 9 different types of bearings on one shaft. The preprocessed other channel data are input into the lightweight gradient ...

Embodiment 2

[0122] During the detection of deformation faults such as wheel wear and axle cracks, the main steps are the same as those of temperature fault detection. For the sake of brevity, only the steps that are different from Embodiment 1 are described here.

[0123] Step 1 is specifically implemented as follows:

[0124] Step 1.1: This step is the same as in Example 1.

[0125] Step 1.2: For the detection of the circumferential wear rate of the wheel tread, construct a lightweight gradient lifting machine model, and use the circumferential wear rate of the wheel tread to predict the target, such as figure 1 It shows the distribution positions of two bogies, four axles and eight wheels in one section of the vehicle. The preprocessed other channel data are input into the lightweight gradient elevator model. Other channel data include static load, dynamic load, traction braking load, vehicle speed , shaft speed, motor speed and other features, on this basis, the selected features of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com