Fractured rock mass permeability test method capable of simulating complex disturbance conditions

A technology of disturbance conditions and test methods, applied in the direction of applying repeated force/pulsation force to test material strength, permeability/surface area analysis, and using one-time impact force to test material strength, etc. It can solve the problem of simple load form and unbreakable rock mass coupling Problems such as testing and exacerbating the difficulty of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

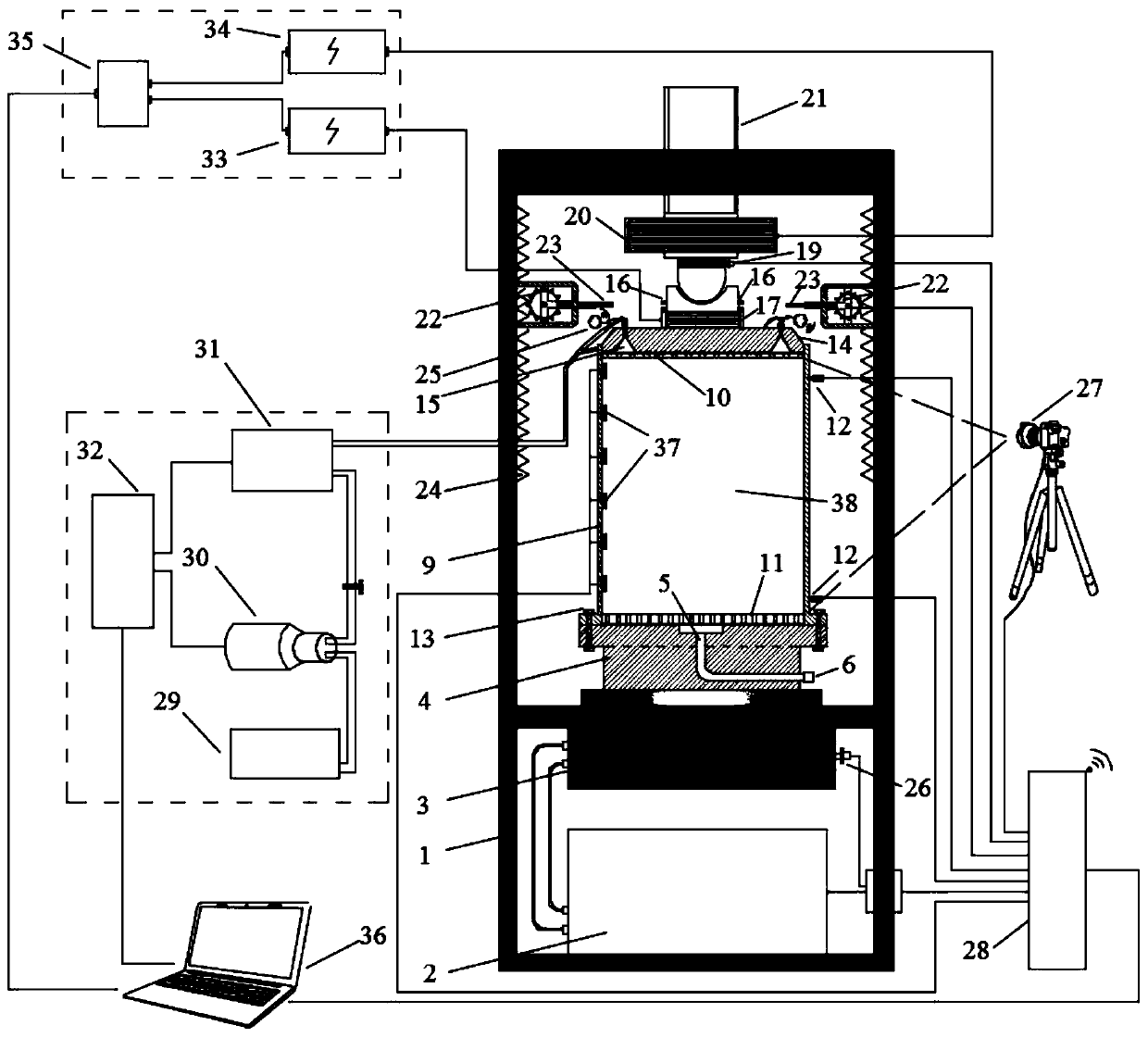

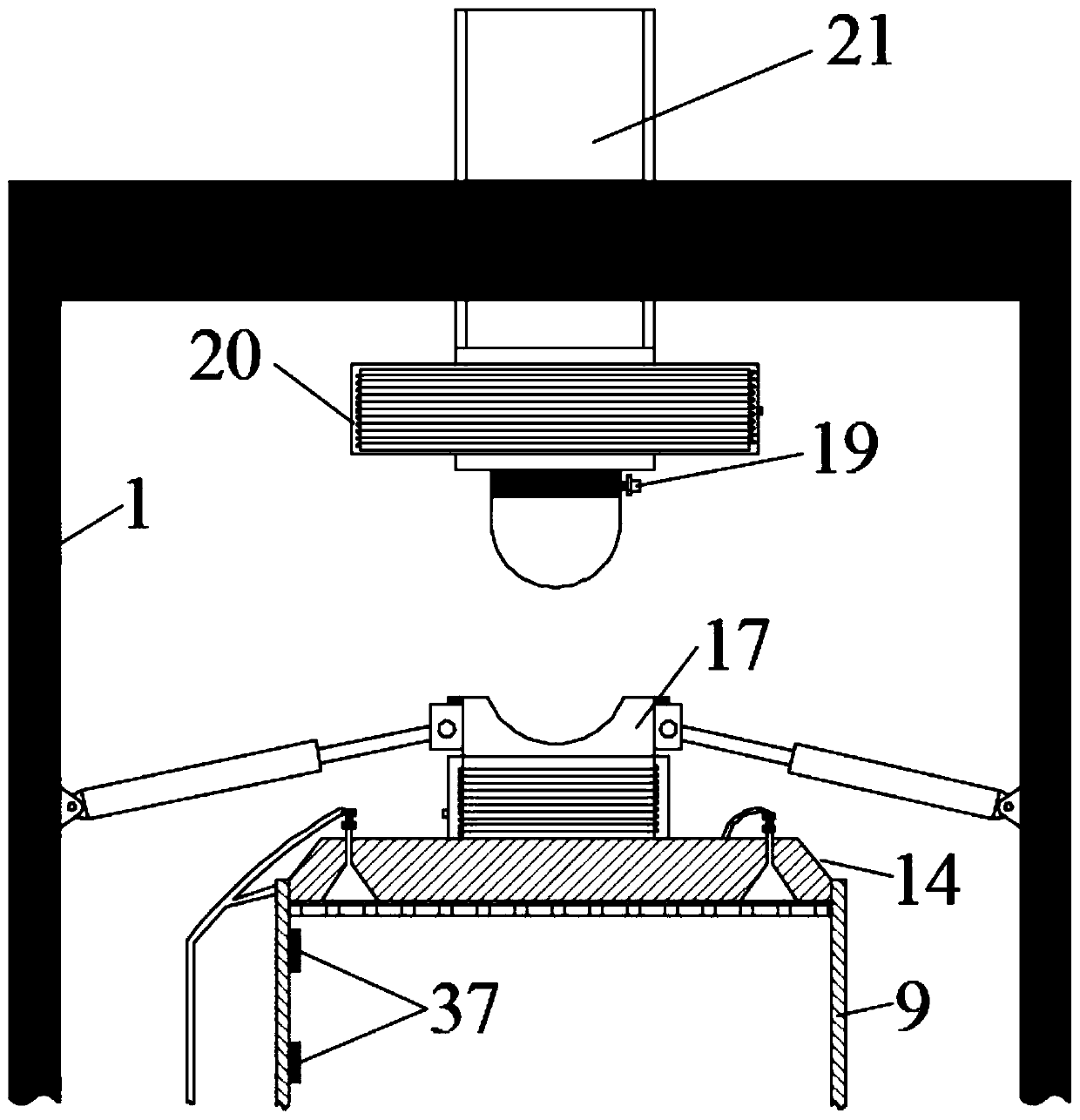

[0039] Such as figure 1 As shown, the broken rock penetration test system includes an integral frame 1, a pressure chamber part, a pressure loading control part, a seepage liquid supply control part, an in-situ disturbance excitation control part, a visual detection part and a centralized electric control part.

[0040] The pressure loading control part is fixedly arranged on the inner bottom of the monolithic frame 1, and includes a hydraulic pump station 2 and a loading hydraulic cylinder 3. The loading hydraulic cylinder 3 is vertically fixedly arranged on the monolithic frame 1, and the loading hydraulic cylinder 3 The telescopic end is pushed out vertically upwards, and the loading hydraulic cylinder 3 is connected with the hydraulic pump station 2 through a hydraulic pipeline and a control valve group.

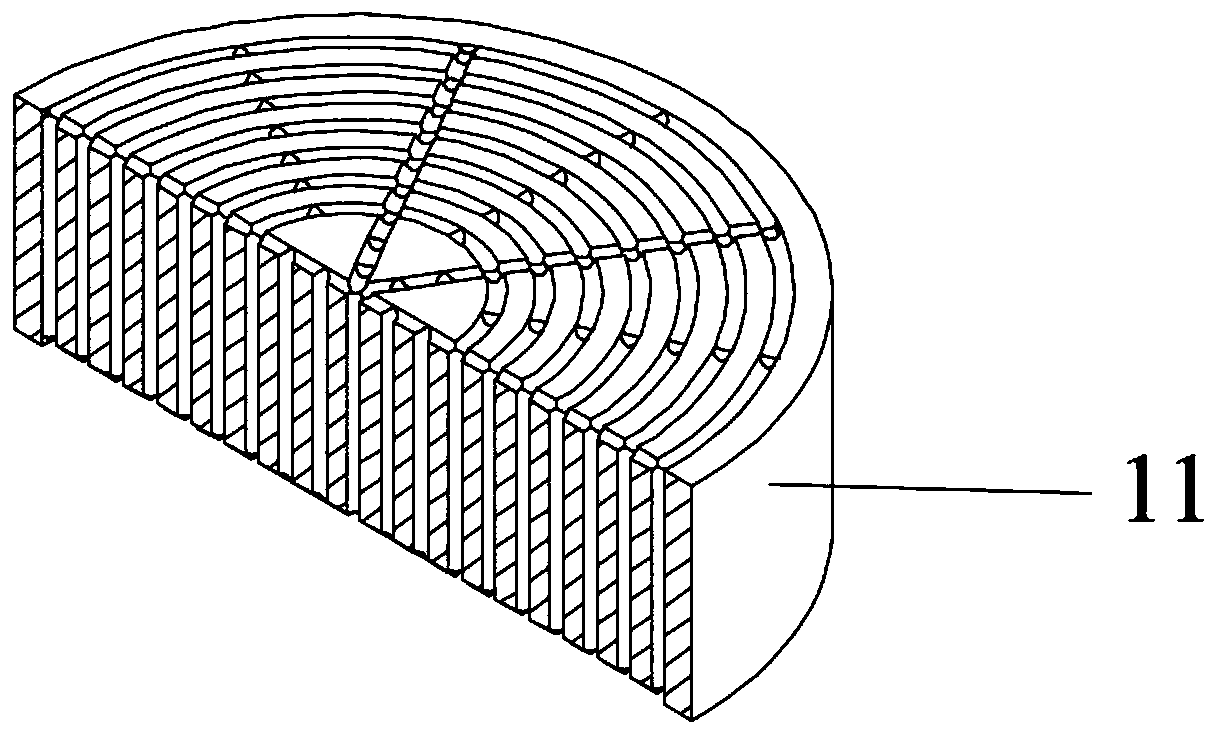

[0041] The pressure chamber part includes a pressure chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com