Continuous variable-diameter metal wire and machining method thereof

A processing method and metal wire technology, applied in the direction of wire drawing dies, slender components, building components, etc., can solve the problems of large deformation rate, etc., and achieve the effect of increasing work efficiency and simple and easy control of processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

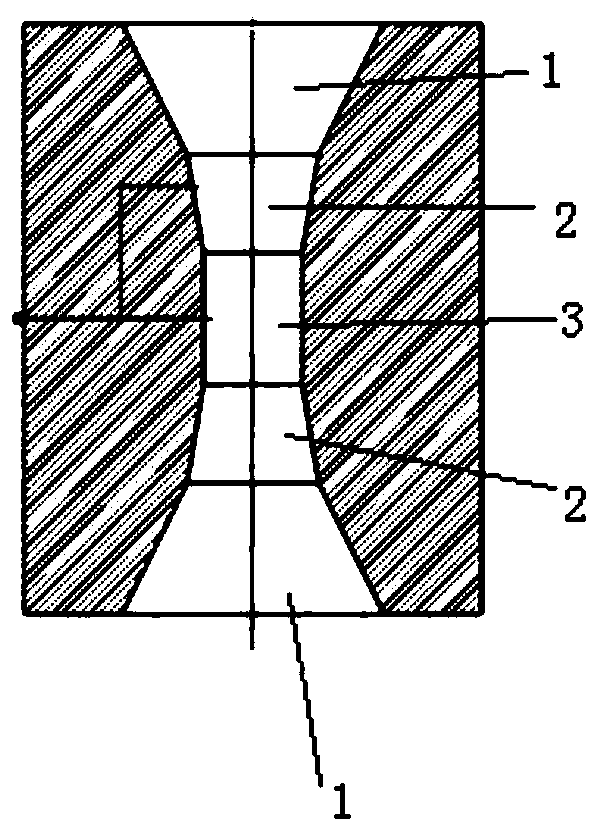

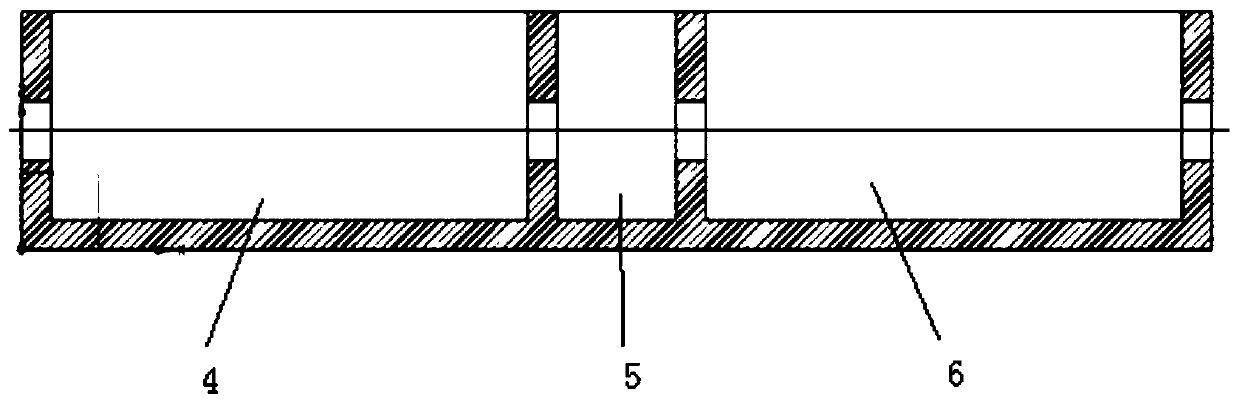

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a metal wire with two kinds of diameter specifications, and its processing method is as follows

[0029] S1: Select 300m of 72A steel wire with a diameter of 5.0mm, pickling, phosphating, and heat treatment.

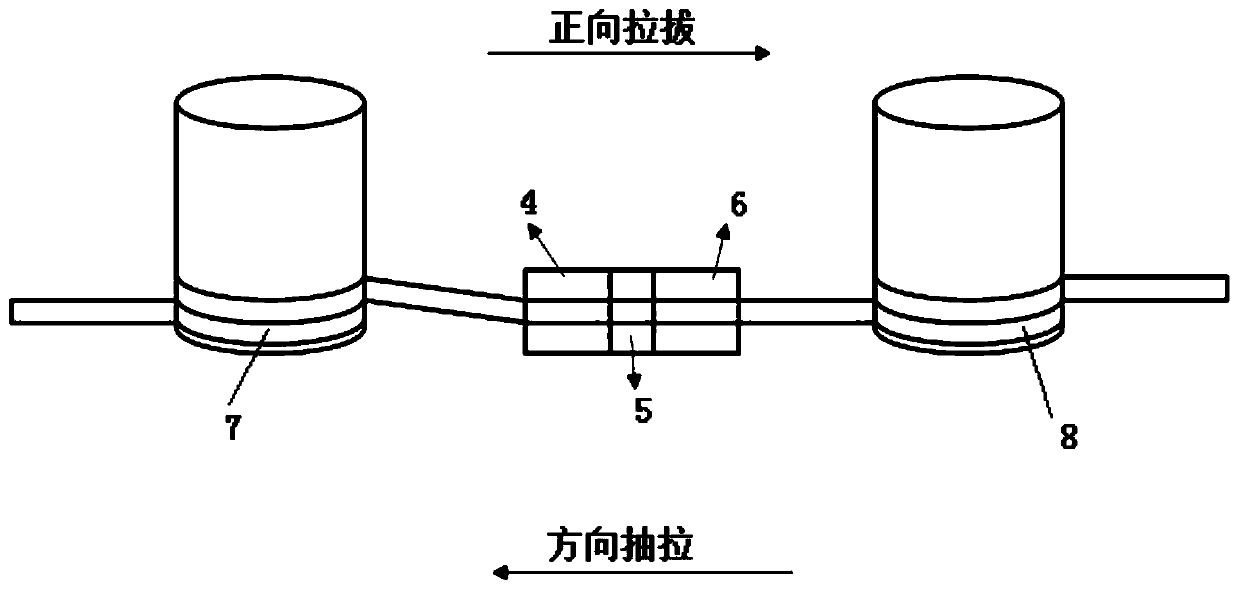

[0030] S2: Forward drawing forming, using a bidirectional drawing system to draw the pretreated 72A steel wire forward into a continuously variable diameter steel wire with a length of 200 m, a diameter of 4.2 mm, and a remaining length of 5.0 mm in diameter. The diameter of the take-up reel is 0.8m, and after 79 rotations, the forward drawing stops.

[0031] S3: Reverse extraction, the 72A steel wire was extracted from the mold in reverse direction using a bidirectional drawing die to prepare continuous 72A steel wires with diameters of 5.0mm and 4.2mm. The strengths of the two sections of steel wire were 1380.3MPa and 1493.7MPa respectively.

Embodiment 2

[0033] This embodiment relates to a kind of wire material with three kinds of diameter specifications, and its processing method is as follows

[0034] S1: Select 7xxx series aluminum alloy wires with a length of 300m and a diameter of 5.0mm, and the aluminum alloy wires are heat-treated at 420°C.

[0035] S2: Combining with the bidirectional drawing system, the pretreated 7xxx series aluminum alloy wire is forward drawn into a continuously variable diameter aluminum alloy wire with a length of 200 m, a diameter of 4.4 mm, and a remaining length of 5.0 mm in diameter.

[0036] S3: Reverse extraction, and then use a bidirectional drawing system to reversely extract the 7xxx series aluminum alloy wires from the mold to prepare continuous 7xxx series aluminum alloy wires with a diameter of 5.0mm and 4.4mm, with strengths of 263.6MPa and 4.4mm respectively. 285.4 MPa.

[0037] S4: Replace the two-way drawing die with a diameter of 3.9 mm for the sizing belt, repeat step S2, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com