Method for controlling rim lubricating system of tramcar

A technology of lubrication system and control method, which is applied in the direction of track lubrication, track wetting/lubrication, railway car body parts, etc., can solve the problems of accumulation, locomotive wheel idling, etc., reduce resistance and noise pollution, improve operability, Effect of improving lubrication efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

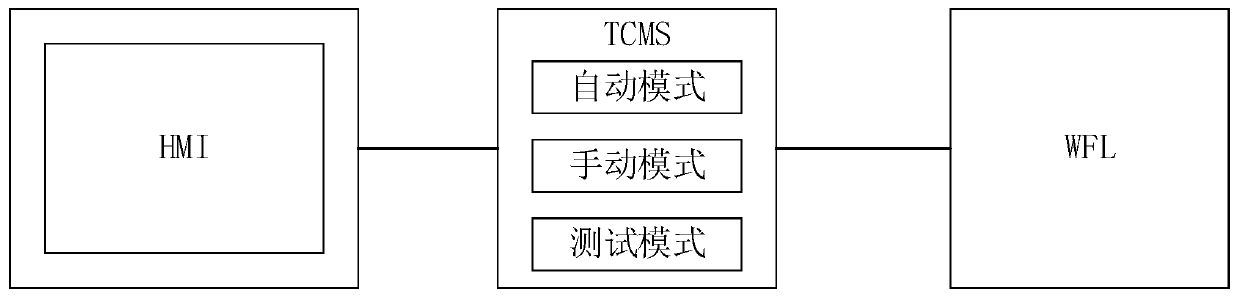

[0053] In this embodiment, the priorities of the three control modes are test mode, manual mode, and automatic mode in sequence. Through reasonable setting of priorities, smooth switching of the three control modes is ensured without affecting the normal use of the rim lubrication system.

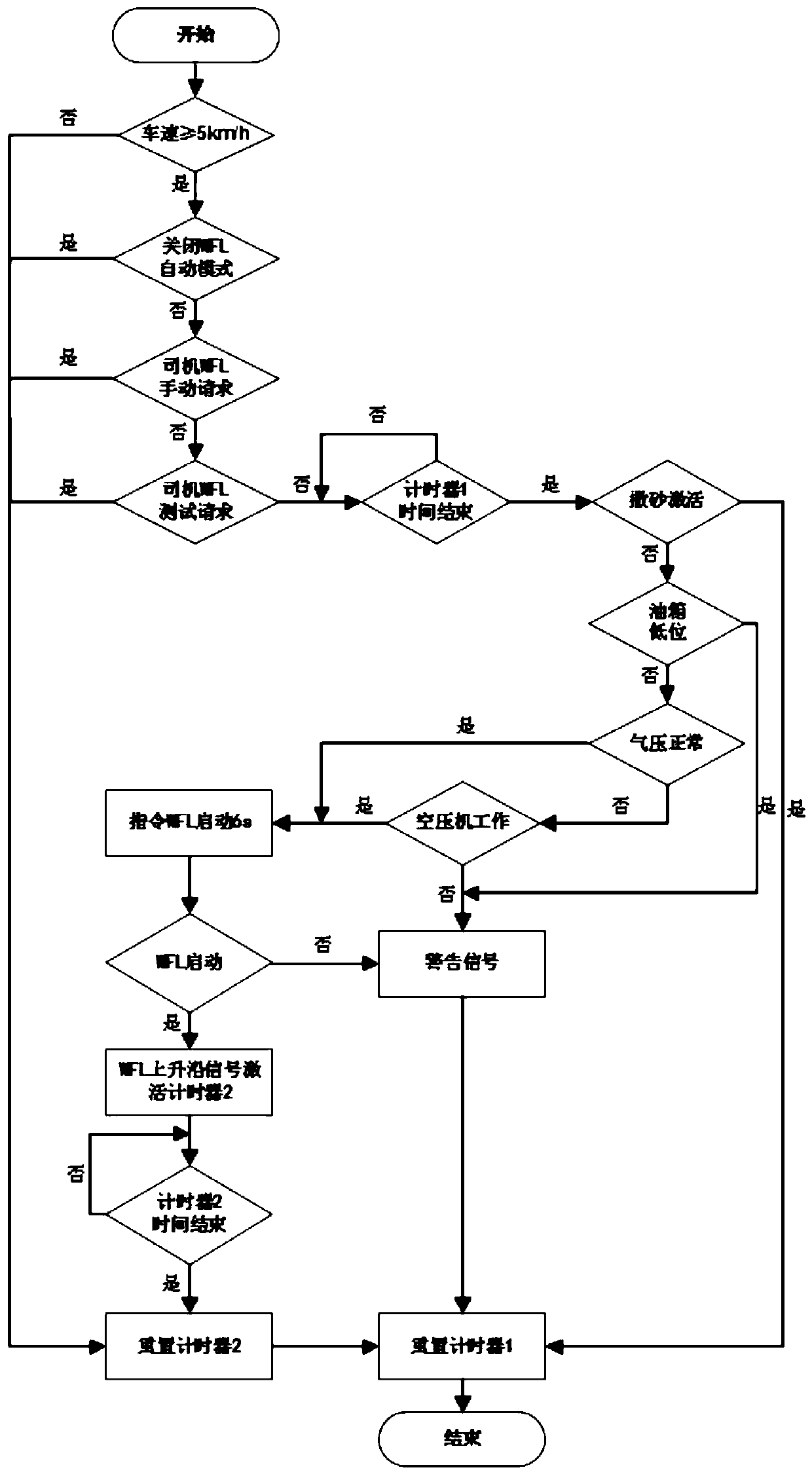

[0054] Such as figure 2 As shown, the control method of the automatic mode is:

[0055] S11: TCMS judges that the current train speed is higher than the rim lubrication low speed limit V (generally V=5km / h), and there is no request to close the automatic mode, WFL manual request or WFL test request, then execute step S12, otherwise reset the timer 2;

[0056] S12: After the timer 1 counts, if the sand spreading system is activated, then reset the timer 1, otherwise execute step S13; wherein, since the sand spreading system is used to realize sand spreading between the tram wheel and the track, increase two The adhesion between the two, and the rim lubrication system is to reduce the adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com