Reversing control device for double conveying channels for paper sheets and working method of reversing control device

A technology of reversing control device and transportation channel, which is applied in the directions of transportation and packaging, sending objects, processing of thin materials, etc., can solve the problems of complex force on the reversing teeth, complicated structure, high price, etc., so as to improve the reversing control. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

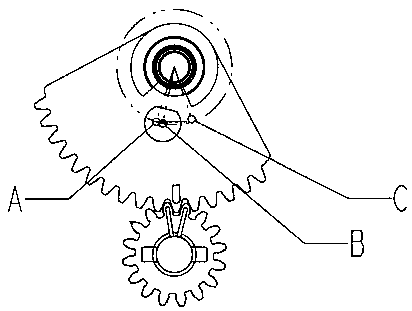

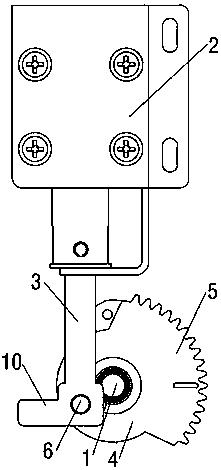

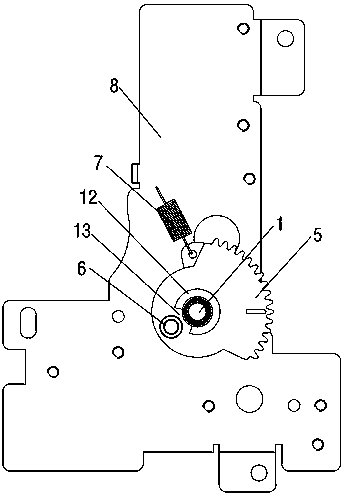

[0047] A reversing control device for double conveying channels of paper sheets, including a commutator shaft 1 and a pull stopper 2 that drives the commutator shaft 1 to rotate forward and reverse to a predetermined angle, and the pull stopper 2 passes through a gear mechanism Connected with the commutator shaft 1, the gear mechanism includes a pull rod 3 and a first gear 4;

[0048]The pull rod 3 can move upwards in a straight line under the action of the pulling force. The tooth structure on the first gear 4 is a fan-shaped structure 5. The pull rod 3 and the first gear 4 are connected by a rotating shaft 6. The rotating shaft One end of 6 is fixed on the first gear 4, and the other end of the rotating shaft 6 is rotationally connected with the pull rod 3. The fixed point between the rotating shaft 6 and the first gear 4, the center of the arc segment without teeth on the first gear and the The center of the fan-shaped arc section with teeth on a gear is located on a straig...

Embodiment 2

[0061] Still adopting 5 mm tension pull stroke, when the dual-channel reversing in the range of 20°-110° is to be carried out, the reversing angle is larger. The technical solution adopted in this application is to add a second gear 11, and the gear mechanism It also includes a second gear 11, the second gear is a circular gear, the second gear and the first gear are transmitted through gear meshing, the second gear is located at one end of the commutator shaft, and the commutator The shaft can rotate forward and reverse with the second gear, and after adding the second gear, it can still achieve dual-channel reversing within the range of 0°-20°, that is, this embodiment can realize the range of 0°-110° Dual channel commutation.

[0062] At the same time, the first gear and the positioning column 15 are rotatably connected through the embedded bearing, and the first gear rotates along the positioning column under the drive of the pulling force, and the meshing drives the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com