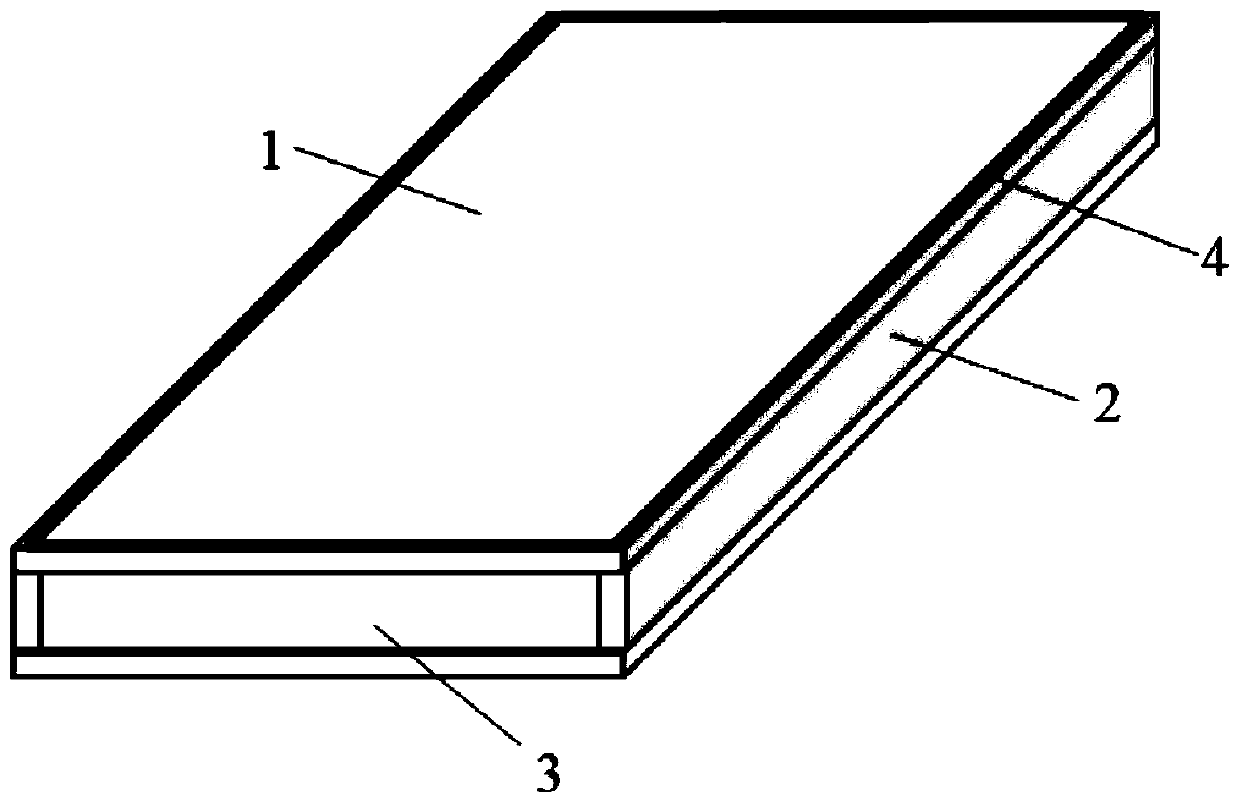

Integrated pouring type composite fireproof glass and preparation method thereof

A technology of fireproof glass and flat glass, applied in the direction of parallel glass structure, non-polymer organic compound adhesive, adhesive additive, etc., can solve the problem of air leakage and fireproof liquid, increase the overall thickness of glass, and glass glue is easy to crush glass and other issues, to achieve the effects of enhanced sealing, easy removal of baffles, and fast setting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0041] Each component of the preparation raw material of the adhesive glue of this preparation example and its parts by weight are: base material HO-[(CH 3 ) 2 SiO] 1500 H is 50 parts, silane crosslinking agent methylsilane is 3 parts, ketoxime crosslinking agent CH 3 Si[ON=C(CH 3 )(C 2 h 5 )] 3 2 parts, 0.03 parts of catalyst tetrakis (trimethylsilyloxy) titanium, 35 parts of filler nano-calcium carbonate (60-80mm), 4 parts of auxiliary triallyl isocyanurate, ethylene 3 parts, 3 parts of silicone oil, 0.6 parts of carbon black in color additives, and 1.4 parts of silicone oil.

preparation example 2

[0054] Each component of the preparation raw material of the adhesive glue of this preparation example and its parts by weight are: base material HO-[(CH 3 ) 2 SiO] 1500 H is 65 parts, silane cross-linking agent methyl silane is 1 part, ketoxime cross-linking agent CH 3 Si[ON=C(CH 3 )(C 2 h 5 )] 3 5 parts, catalyst tetrakis (trimethylsiloxy) titanium is 0.05 parts, filler nano calcium carbonate (60-80mm) is 25 parts, auxiliary agent triallyl isocyanurate is 2 parts, ethylene is 1 part, 5 parts of silicone oil, 1.3 parts of carbon black in color additives, and 2.7 parts of silicone oil.

preparation example 3

[0056] Each component of the preparation raw material of the adhesive glue of this preparation example and its parts by weight are: base material HO-[(CH 3 ) 2 SiO] 1500 H is 60 parts, silane crosslinking agent methylsilane is 2 parts, ketoxime crosslinking agent CH 3 Si[ON=C(CH 3 )(C 2 h 5 )] 3 1 part, 0.01 part of catalyst tetrakis (trimethylsiloxy) titanium, 30 parts of filler nano-calcium carbonate (60-80mm), 3 parts of auxiliary triallyl isocyanurate, ethylene 2 parts, 4 parts of silicone oil, 0.8 parts of carbon black in color additives, and 2.2 parts of silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com