Method for coating silicon carbide on graphite substrate

A technology of graphite substrate and coating method, applied in the field of silicon carbide coating, can solve problems such as handling difficulties, and achieve the effects of economical production, high durability and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the present invention will be described in more detail with reference to the drawings and embodiments. However, the following drawings and examples are merely exemplary contents for explaining the content and scope of the technical idea of the present invention, and the technical scope of the present invention is not limited or changed accordingly. Relevant practitioners can perform various modifications or changes within the scope of the technical idea of the present invention on the basis of the following exemplary contents.

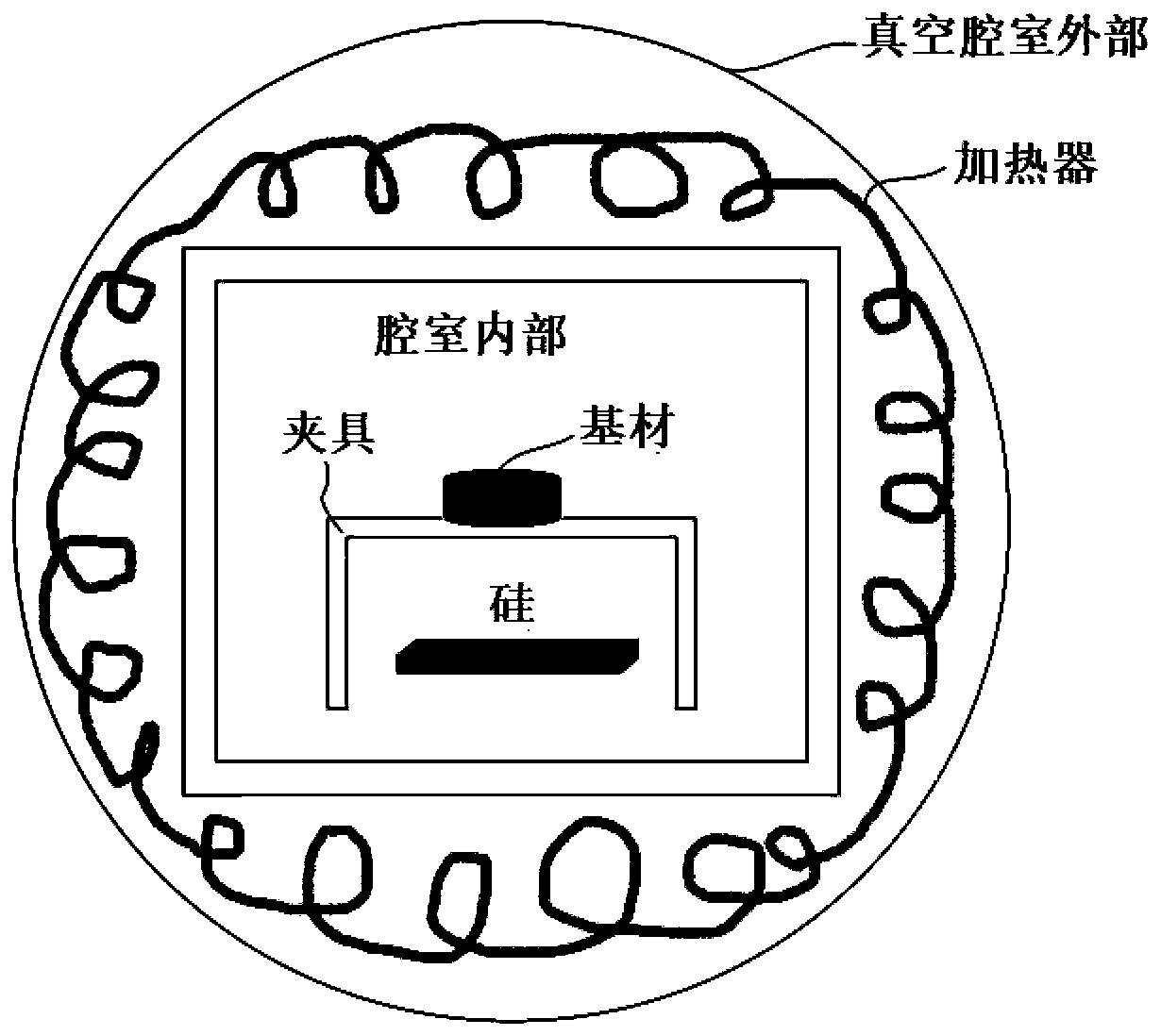

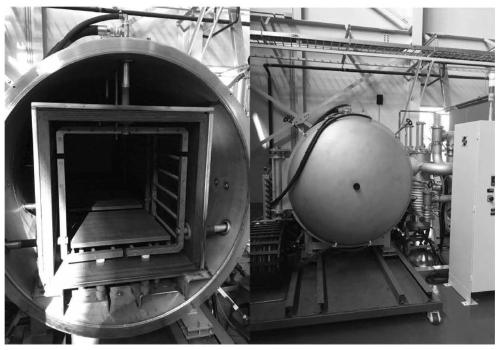

[0027] As described above, the present invention relates to a silicon carbide coating method for a graphite substrate, which is characterized in that: after the graphite substrate and solid silicon (Si) for forming the coating are put into a vacuum chamber, the Heat treatment at 2,000°C.

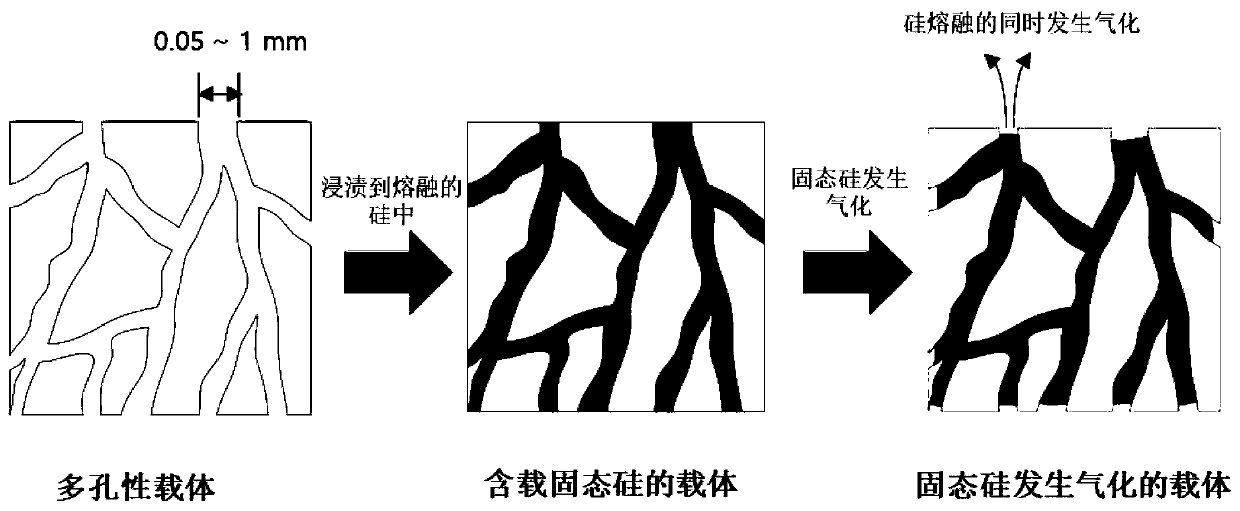

[0028] Silicon has a melting point of 1414°C and a boiling point of 3265°C at room temperature, but when the pressure decreases, the boiling point ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com