Modular continuous pyrolysis internal rotation type reaction kettle device

A pyrolysis reaction kettle and inner rotation technology, which is applied in the field of modular continuous pyrolysis inner rotation reaction kettle devices, can solve the problems that the kettle body cannot be modularized and interchangeable, the operation cost is high, and the overall scrapping, etc. The effect of production and operation cost, low operation cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

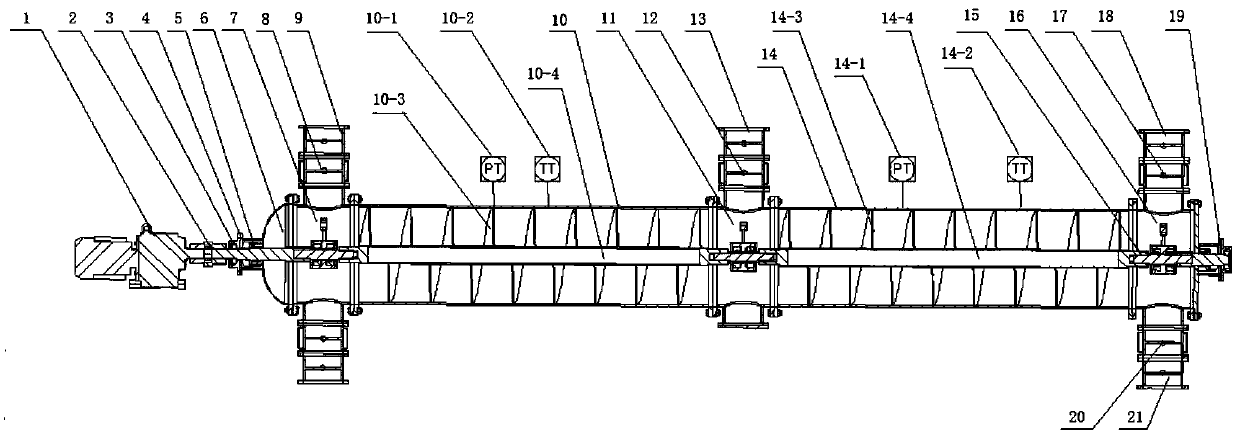

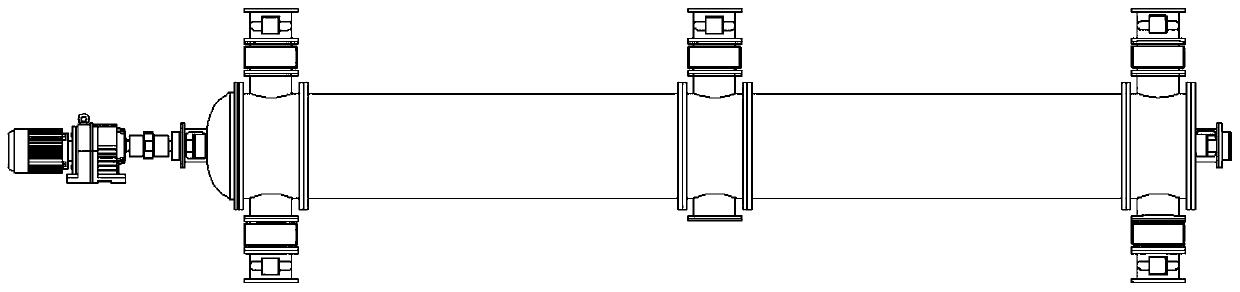

[0042] like Figure 1-2 As shown, the modular continuous pyrolysis internal rotation reactor device provided by this embodiment includes:

[0043] The sealing stuffing box 5 and the left end sealing head 6, the left end sealing head 6 is arranged on the sealing stuffing box 5;

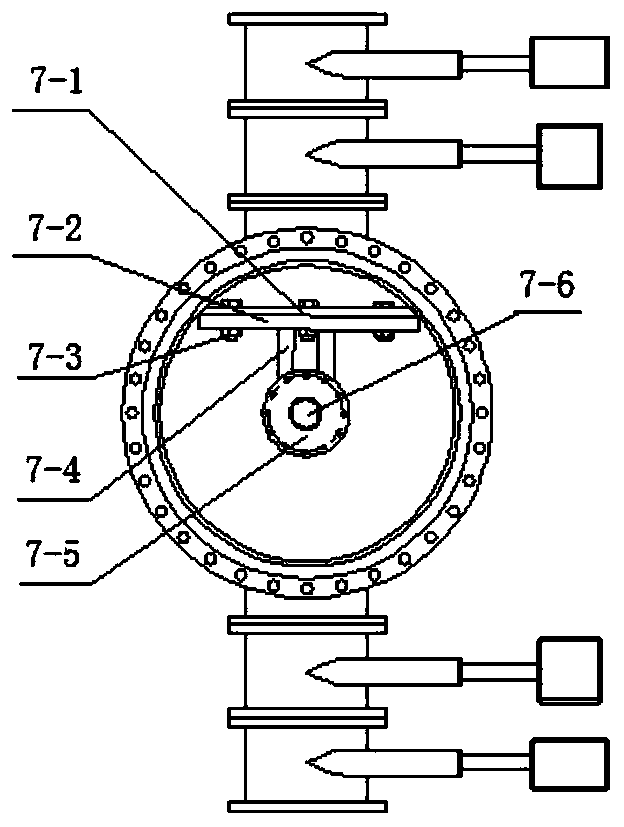

[0044] The feed end connection module 7 is an interchangeable general component, and its left and right ends as well as its upper and lower ends are provided with flanges, the upper end flange is an open flange, and the feed end The left end flange of the end connection module 7 is connected with the left end cover 6; in this embodiment, the upper end flange of the feed end connection module 7 is an open flange, and its function is to facilitate the installation and maintenance of the hanging shaft, and to facilitate the Replace the connection between the accessories and the module.

[0045] The first inner rotation type pyrolysis reaction kettle cylinder 10, the left and right ends of the first inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com