A kind of hydrophobic element book paper and preparation method thereof

A meta-book paper and hydrophobic technology, which is applied in the field of papermaking, can solve the problems of high moisture absorption, mildew of artworks, and large demand for product differentiation, so as to improve the bonding force between fibers, prevent moisture absorption and mildew, and prolong storage the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

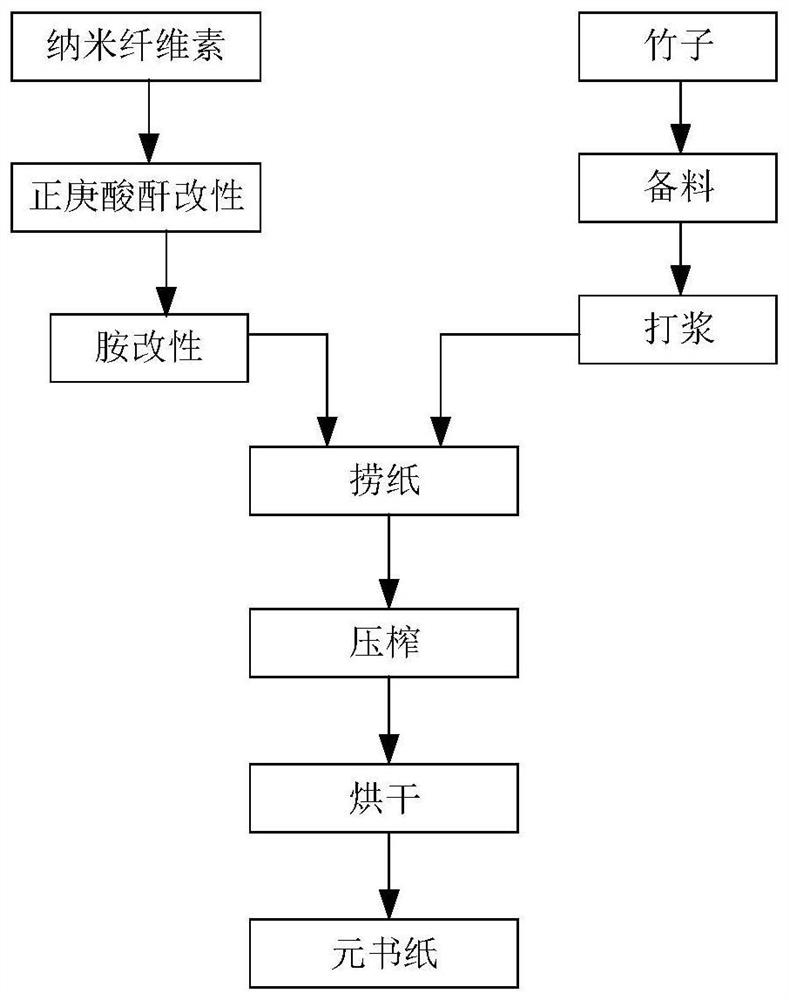

Method used

Image

Examples

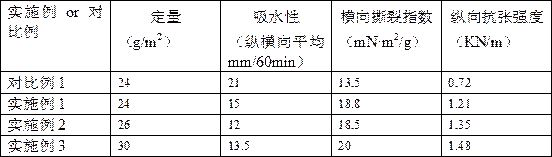

Embodiment 1

[0040] A kind of preparation method of hydrophobic element book paper of the present embodiment, described method comprises the steps:

[0041](1) Prepare the purchased oxidized nanocellulose (that is, cotton pulp nanocellulose prepared by TEMPO oxidation-high pressure homogenization) into a nanocellulose aqueous suspension with a concentration of 1%; Concentration of 1.0% nanocellulose water suspension is evaporated to make the suspension gel-like; then in another reactor, the dispersant N-N-dimethylformamide and gel-like nanocellulose are mixed according to the ratio Evenly, heat up to 85°C and keep stirring for 4 hours, continue to add n-heptanoic anhydride and 4-dimethylaminopyridine, disperse at high speed (800 rpm) for 15 minutes, and heat up to 100°C, react for 2 hours, cool for 15 minutes, and then use methanol and Washing with deionized water to obtain anhydride-modified nanocellulose; wherein: the mass ratio of nanocellulose, n-heptanoic anhydride, and 4-dimethylamin...

Embodiment 2

[0045] A kind of preparation method of hydrophobic element book paper of the present embodiment, described method comprises the steps:

[0046] (1) Prepare the purchased oxidized nanocellulose (that is, cotton pulp nanocellulose prepared by TEMPO oxidation-high pressure homogenization) into a nanocellulose aqueous suspension with a concentration of 0.8%; Concentration of 1.0% nanocellulose water suspension is evaporated to make the suspension gel-like; then in another reactor, the dispersant N-N-dimethylformamide and gel-like nanocellulose are mixed according to the ratio Evenly, heat up to 80°C and keep stirring for 8 hours, continue to add n-heptanoic anhydride and 4-dimethylaminopyridine, disperse at high speed (1000 rpm) for 20 minutes, and heat up to 100°C, react for 4 hours, cool for 20 minutes, and then use methanol and Washing with deionized water to obtain anhydride-modified nanocellulose; wherein: the mass ratio of nanocellulose, n-heptanoic anhydride, and 4-dimethyl...

Embodiment 3

[0050] A kind of preparation method of hydrophobic element book paper of the present embodiment, described method comprises the steps:

[0051] (1) Prepare the purchased oxidized nanocellulose (that is, cotton pulp nanocellulose prepared by TEMPO oxidation-high pressure homogenization) into a nanocellulose aqueous suspension with a concentration of 1.2%; Concentration of 1.0% nanocellulose water suspension is evaporated to make the suspension gel-like; then in another reactor, the dispersant N-N-dimethylformamide and gel-like nanocellulose are mixed according to the ratio Evenly, heat up to 80°C and keep stirring for 6 hours, continue to add n-heptanoic anhydride and 4-dimethylaminopyridine, disperse at high speed (2000 rpm) for 10 minutes, and heat up to 100°C, react for 3 hours and cool for 15 minutes, then use methanol and Washing with deionized water to obtain anhydride-modified nanocellulose; wherein: the mass ratio of nanocellulose, n-heptanoic anhydride, and 4-dimethyla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com