Connection rod assembly for piston compressor

A technology of connecting rod components and compressors, which is applied in the direction of variable capacity pump components, liquid variable capacity machines, pump components, etc., can solve problems such as easy breakage, large force on the small end of the connecting rod, and machine damage, etc., to achieve Reduce economic losses, reduce maintenance frequency, and improve practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

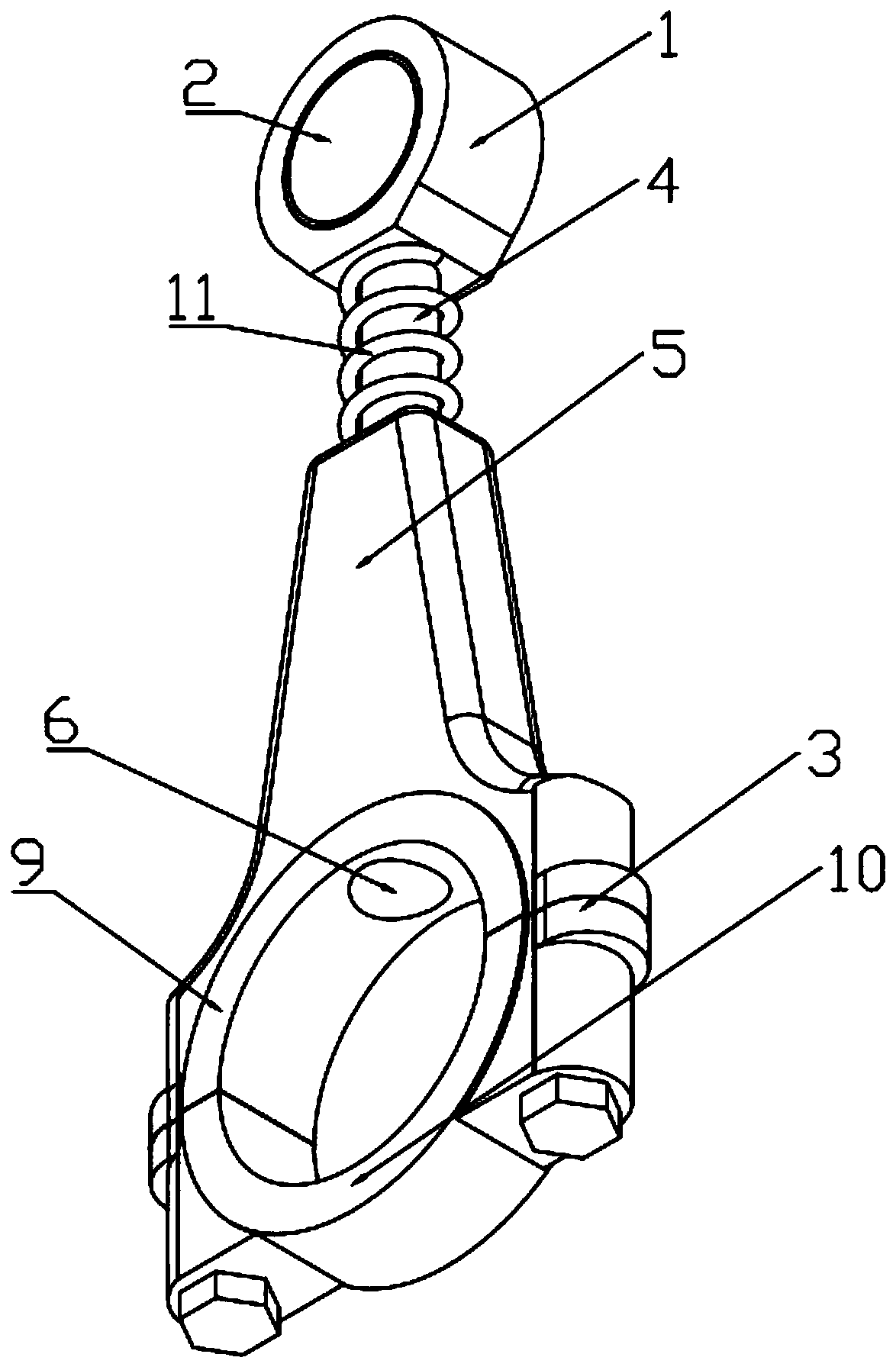

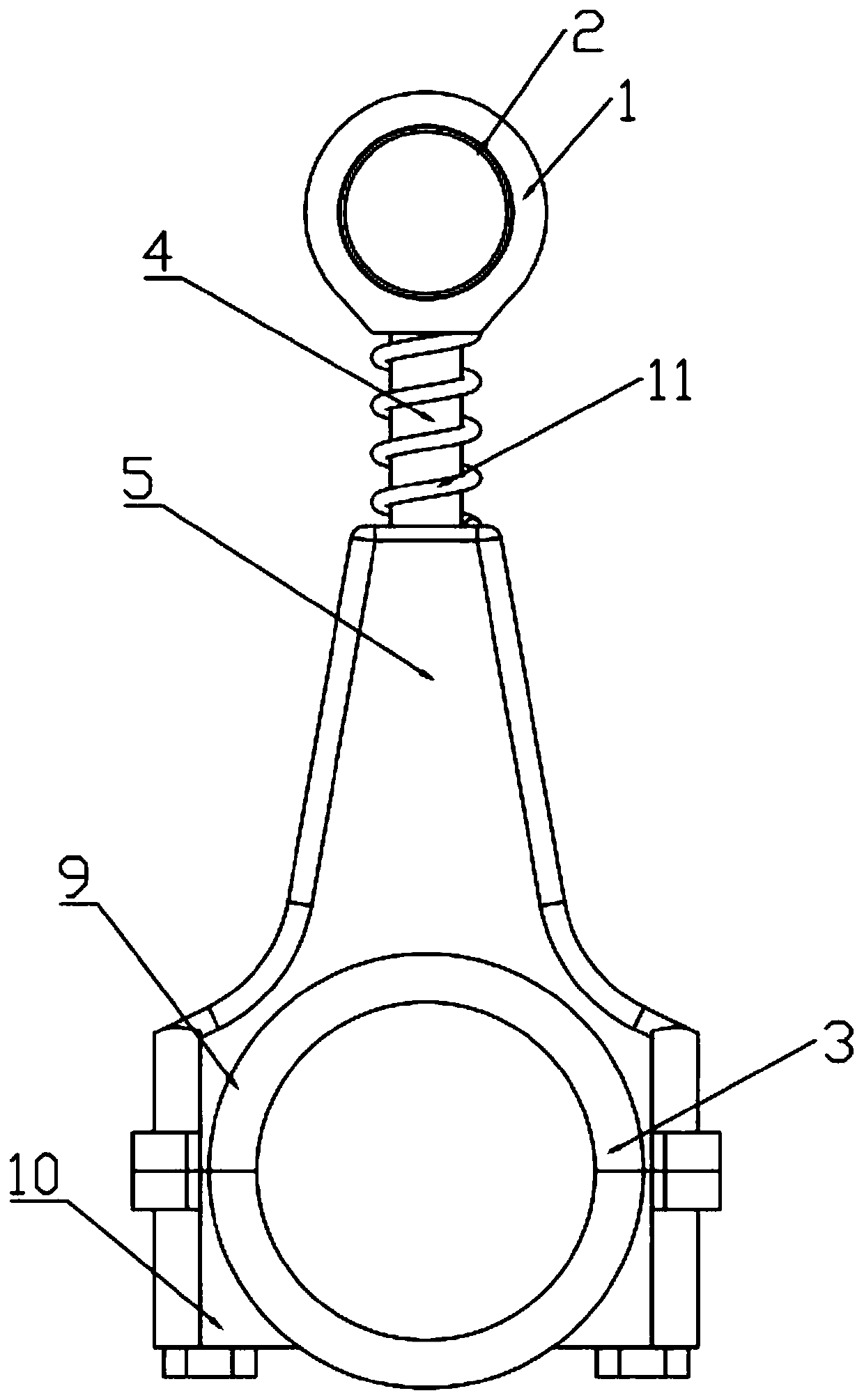

[0019] A connecting rod assembly for a piston compressor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] combined with Figure 1-7 , a connecting rod assembly for a piston compressor, comprising a connecting rod small end 1, a small end bushing ring 2, and a connecting rod large end device 3; the connecting rod small end 1 is fixedly connected with a first connecting rod 4, and the connecting rod The rod big end device 3 is fixedly connected with a second connecting rod 5, and the second connecting rod 5 is provided with a sliding hole 6 along its extending direction, and the sliding hole 6 is provided with an inner hexagonal hole 7, and the first connecting rod 4 is provided with a hexagonal prism 12 that is slidingly fitted with the inner hexagonal hole 7 at the end away from the small end 1 of the connecting rod, and the end of the hexagonal prism 12 away from the small end 1 of the connecting rod is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com