Low-distortion moving coil framework structure of electric vibration table

A technology of electric vibration table and skeleton structure, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc. It can solve the problems of affecting the resonance frequency of the moving coil, reducing the surface resonance of the moving coil, and complex processes, etc. The effect of reducing the distortion of the coil waveform, reducing the vibration noise of the moving coil, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

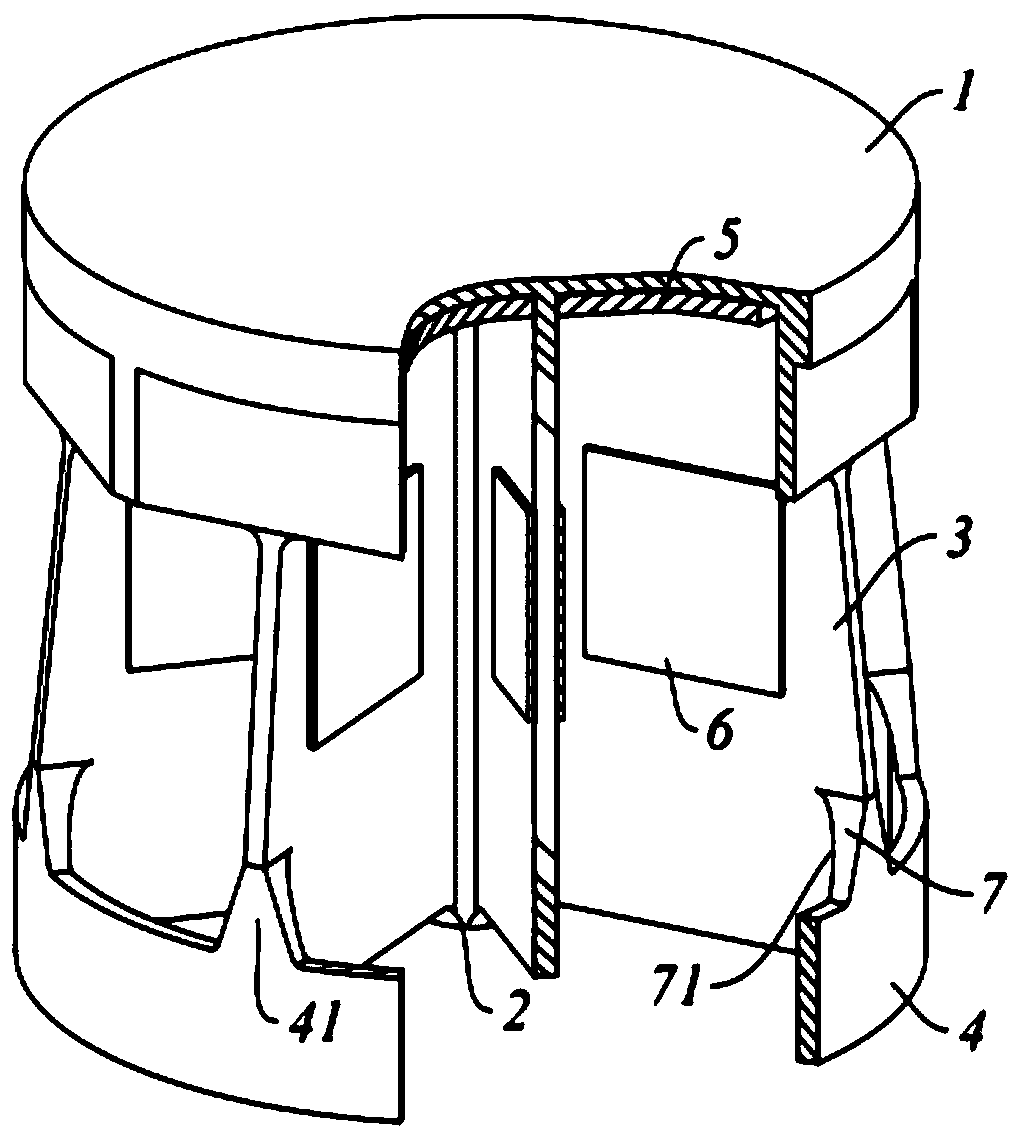

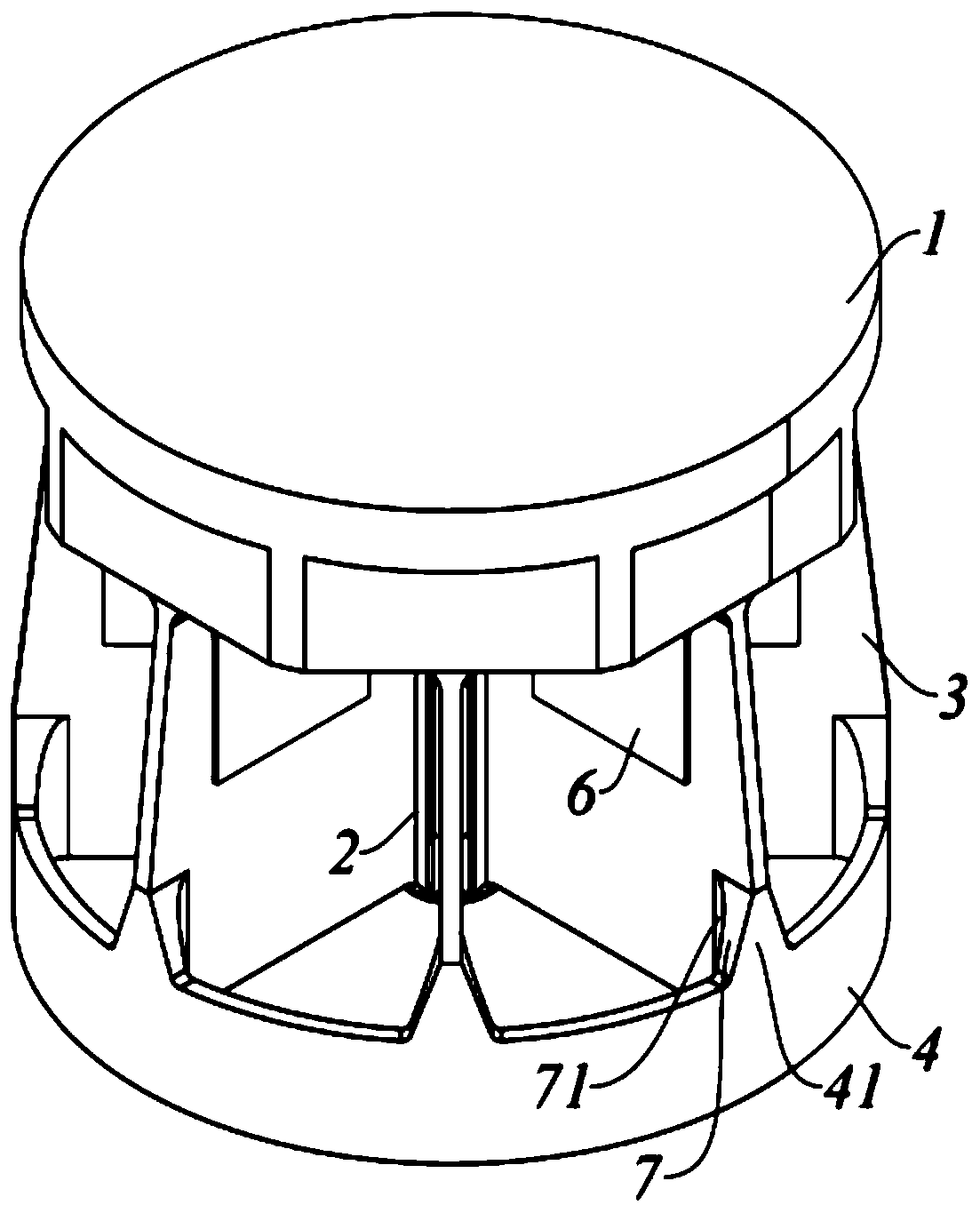

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0026] Please refer to Figure 1~4 , the present invention includes:

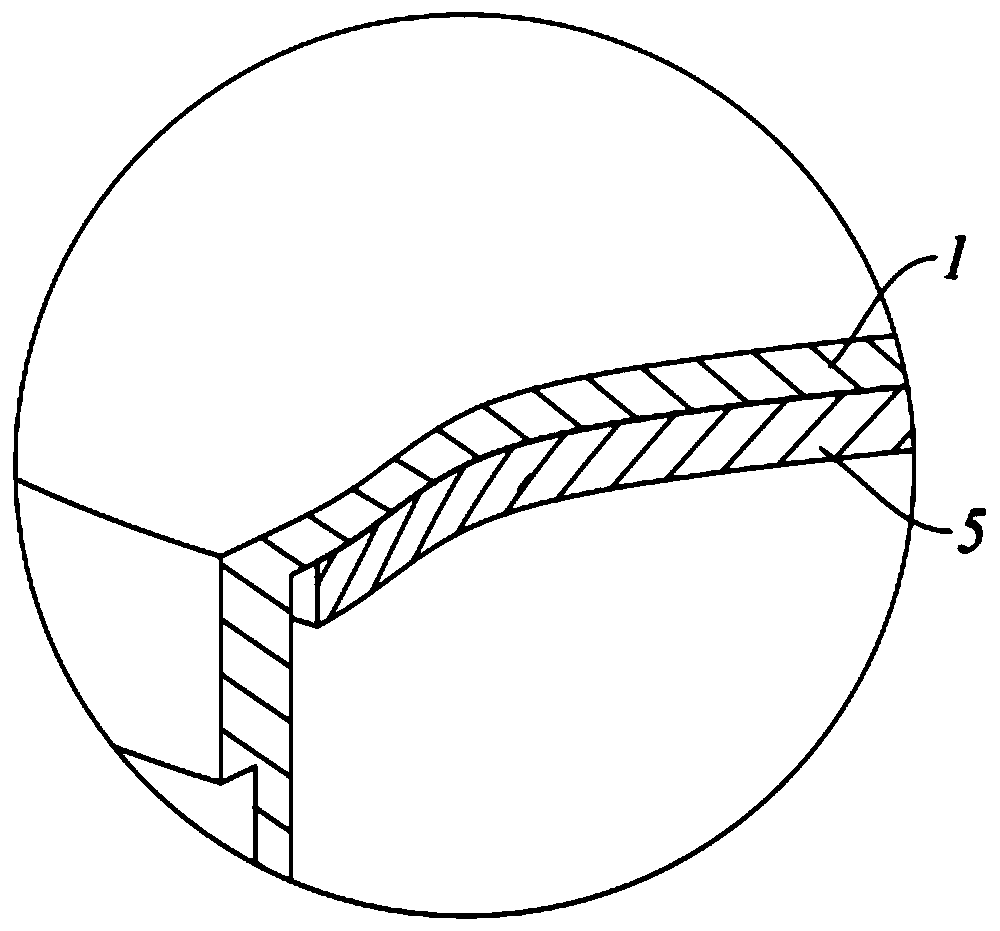

[0027] A low-distortion moving coil skeleton structure for an electric vibrating table, comprising: a table top 1, a center column 2, ribs 3, and skirt boards 4, wherein multiple ribs 3 are connected between the table top 1 and the skirt board 4 and centered on The columns 2 are evenly distributed in the center, the lower surface of the table 1 is pasted with a damping plate 5 , and the left and right side walls of the rib plate 3 are symmetrically pasted with damping blocks 6 .

[0028] Wherein, the damping plate 5 has several pieces uniformly distributed around the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com