Prediction method of NOx emission concentration in boilers with wide load based on model transfer

A technology of emission concentration and prediction method, which is applied in the direction of prediction, neural learning method, biological neural network model, etc., can solve the problems of limited applicability, difficulty in guaranteeing model applicability, and small data sample coverage, and achieve fast and accurate prediction. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

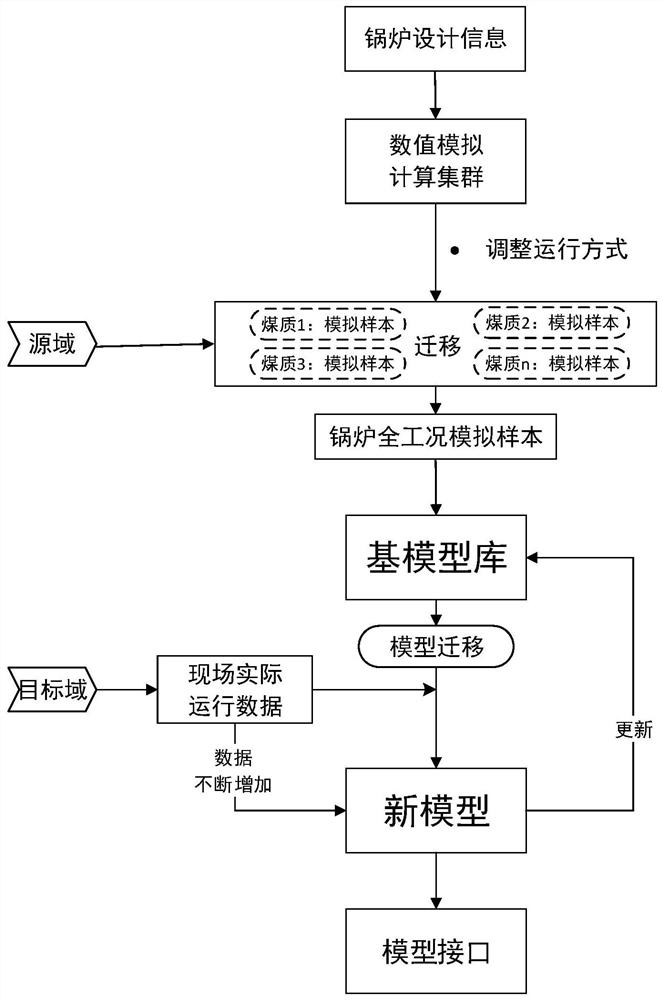

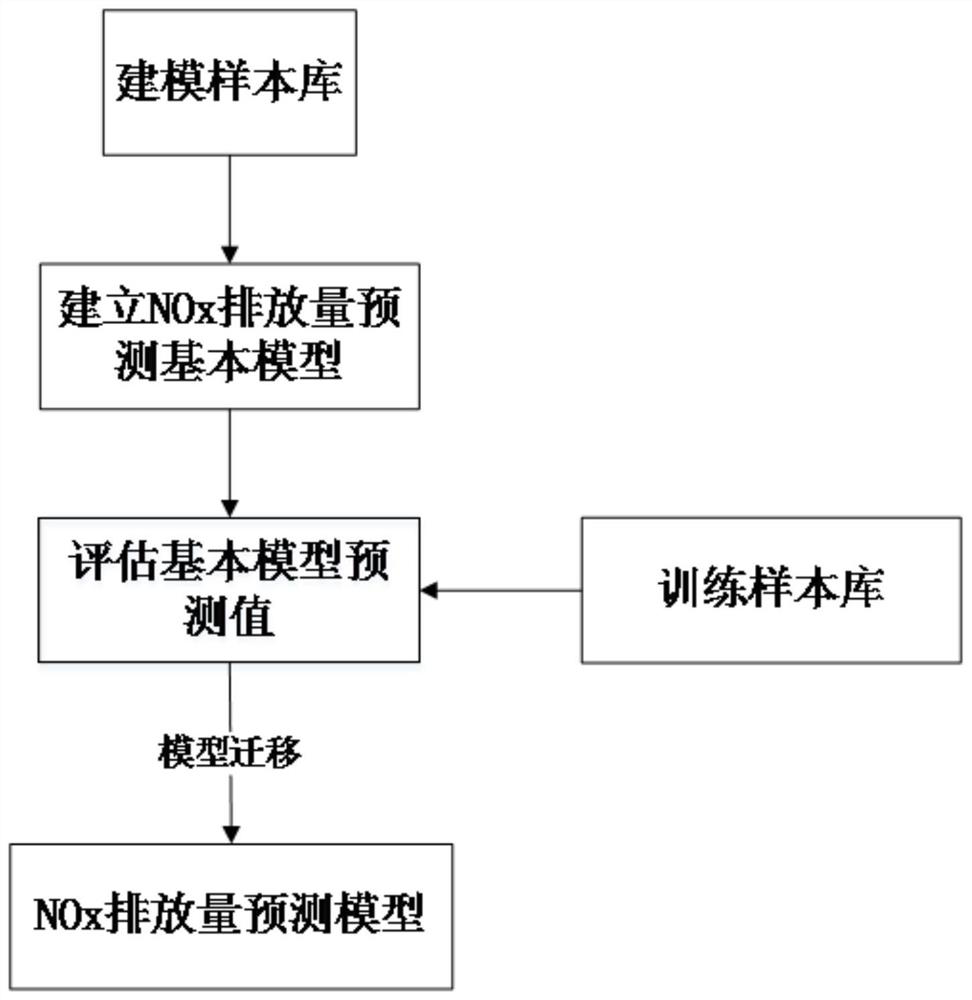

[0049] figure 1 This is the modeling process of the NOx prediction method for boiler wide load in the embodiment of the present invention. like figure 1 As shown, the modeling process includes:

[0050] (1) Combine the boiler design information and fuel characteristics to determine the distribution range of main operating parameters such as load, damper opening, and oxygen content;

[0051] Specifically, boiler design information includes all information related to boiler combustion, such as geometric structure and burner arrangement, and fuel characteristics include all information that affects pulverized coal combustion, such as industrial coal quality analysis, element analysis, and particle size distribution.

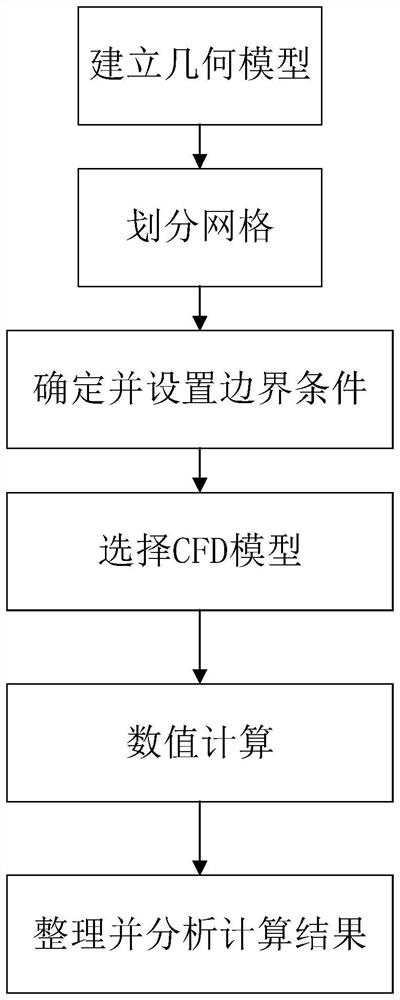

[0052] (2) Combined with the theoretical feasible region of boundary conditions, the orthogonal test method is used to carry out CFD numerical test for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com