Battery module and assembling method thereof

A technology of battery modules and batteries, which is applied to battery pack parts, secondary batteries, assembled battery machines, etc., can solve problems such as inaccurate temperature measurement of battery packs, arrangement of temperature measurement components, etc., and reduce misjudgment and inaccurate response Timely risks, effects of thermal runaway prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

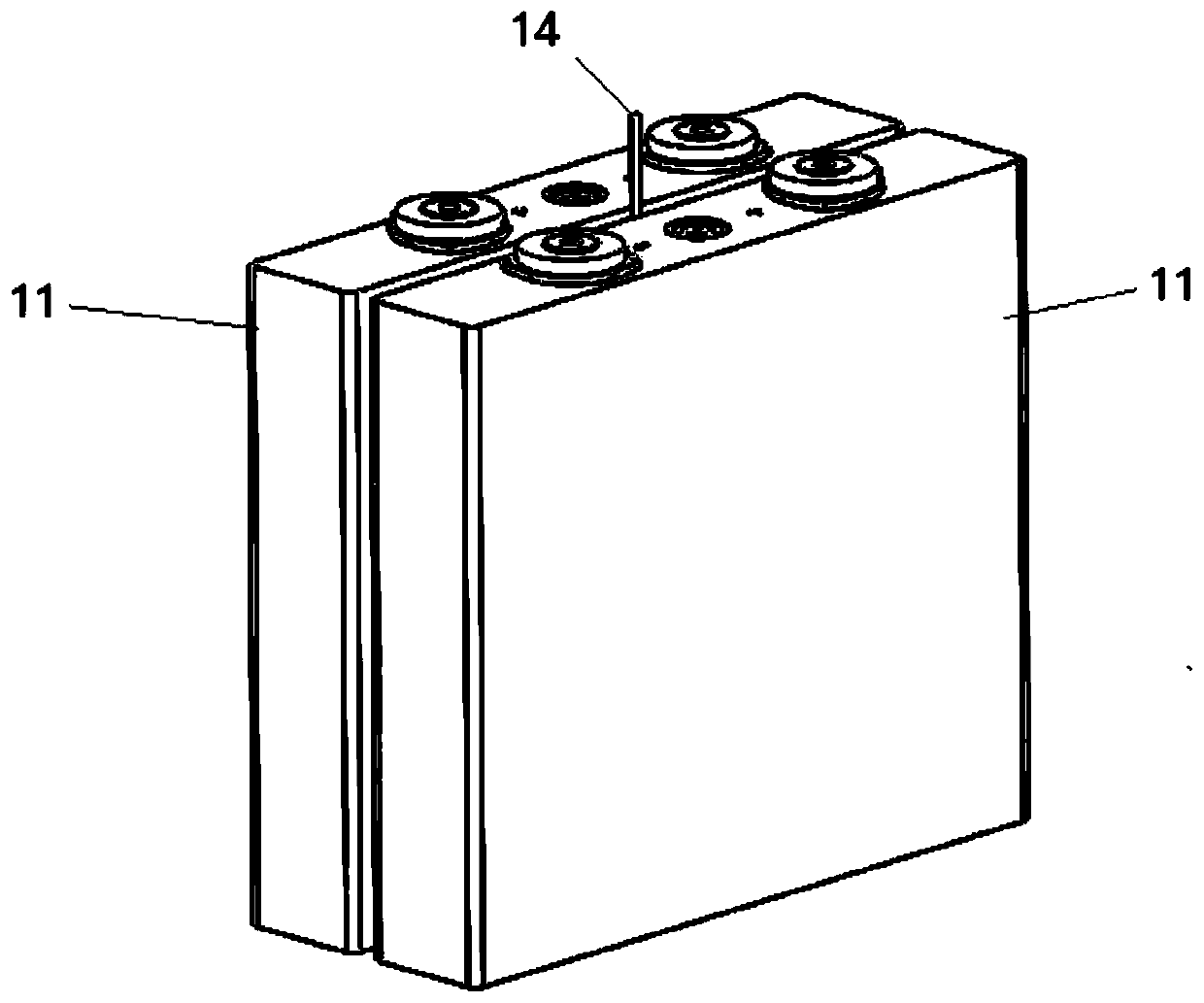

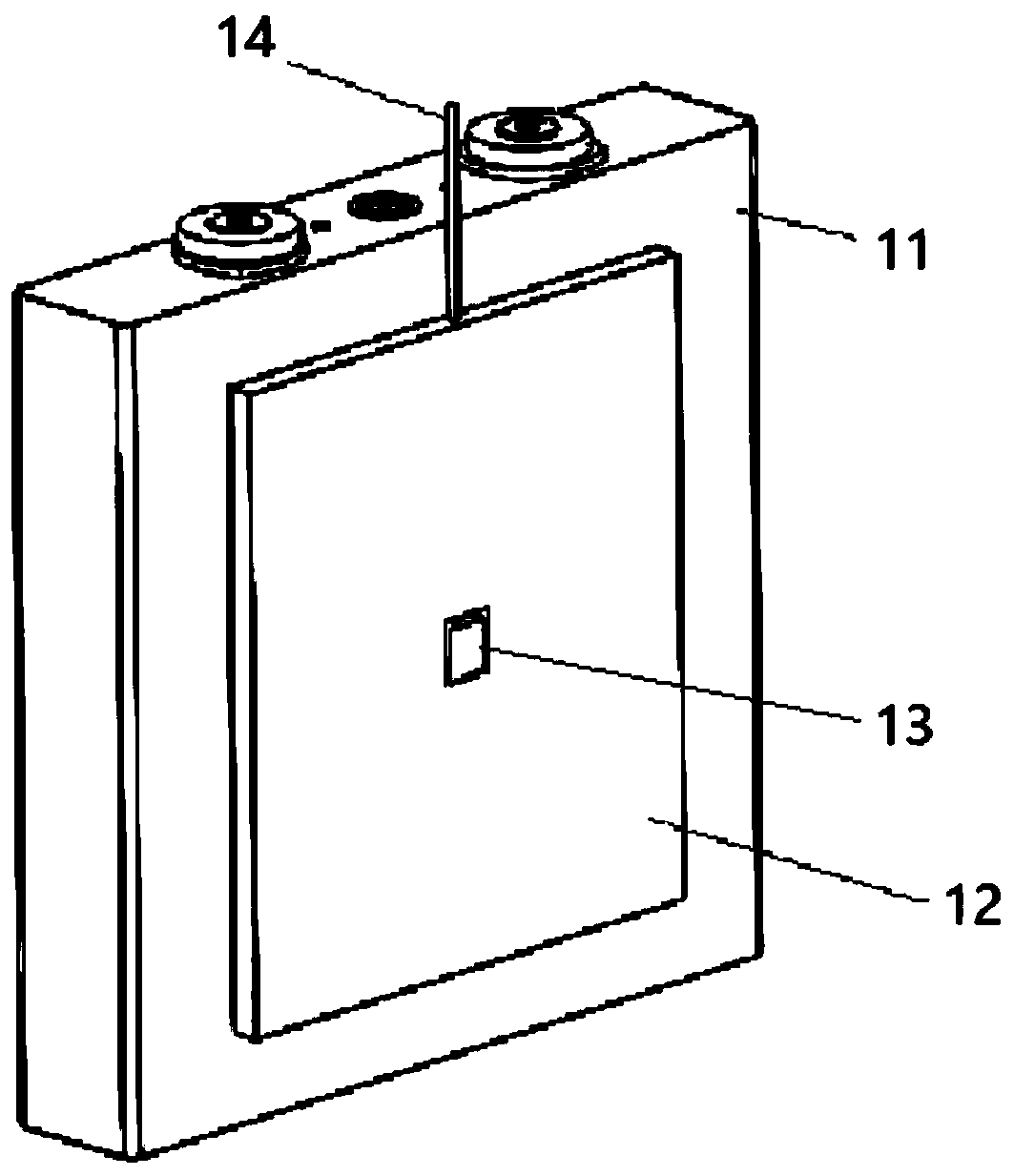

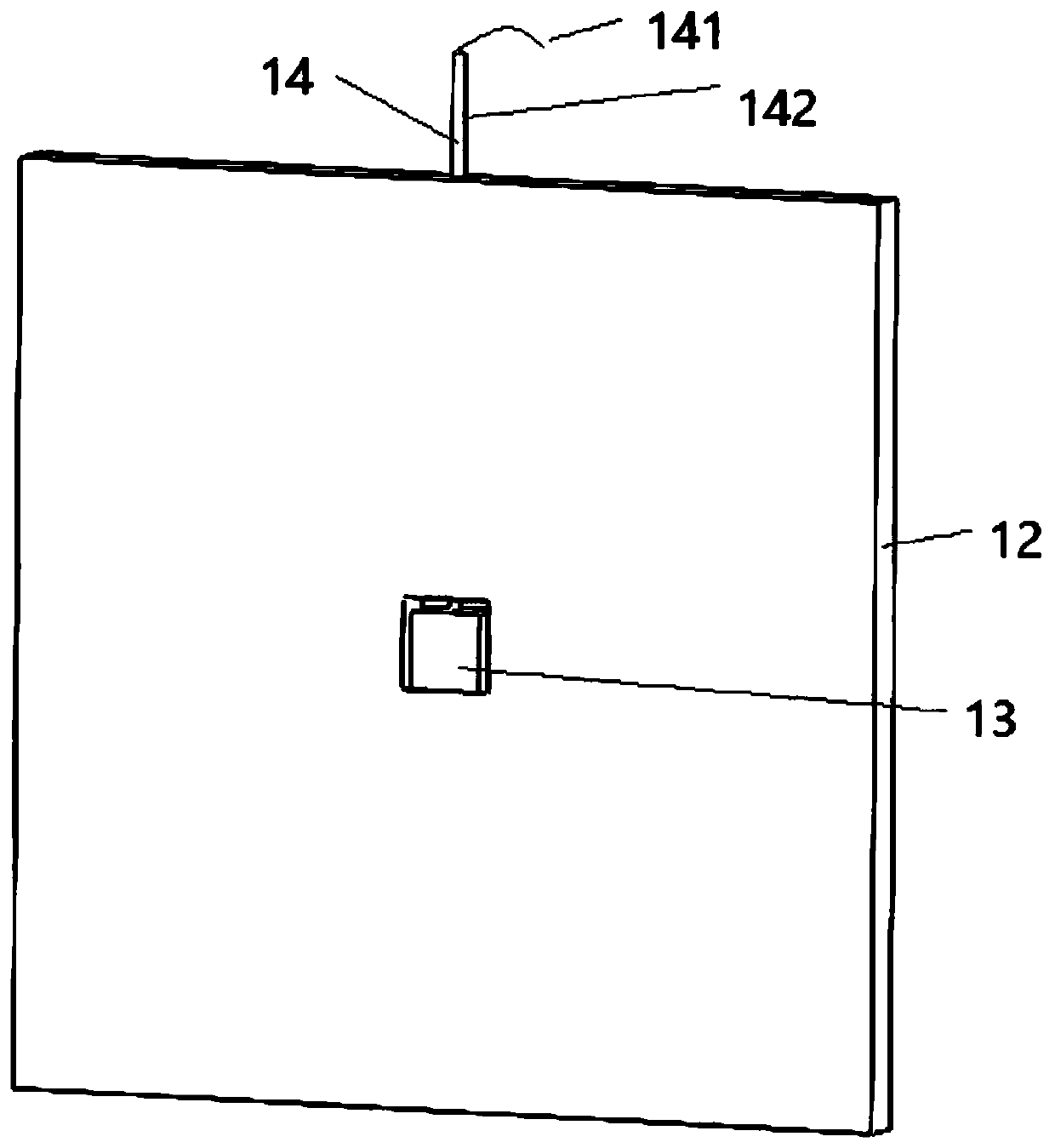

[0024] Embodiments of the present application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, various embodiments in the present application and various features therein can be combined arbitrarily with each other.

[0025] In the field of lithium-ion battery modules, in order to increase the energy density, it is necessary to use battery materials with high specific energy and make lightweight and compact designs. This requires the battery pack to have high heat dissipation performance and heat transfer performance, and has a measurement A temperature measurement system with high precision, short response time, and high anti-interference stability.

[0026] As mentioned above, in the related art, the heat dissipation performance and temperature consistency of the battery pack are improved by simply adding various types of thermal conductive films and heat sinks, and the temperature of the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com