Production method for fermented bread

A production method, bread technology, applied in the direction of dough mixing/kneading method, dough mixer, baking, etc., can solve the problems of reduced efficiency, and achieve the effects of improving efficiency, reducing pollution, and improving the rounding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

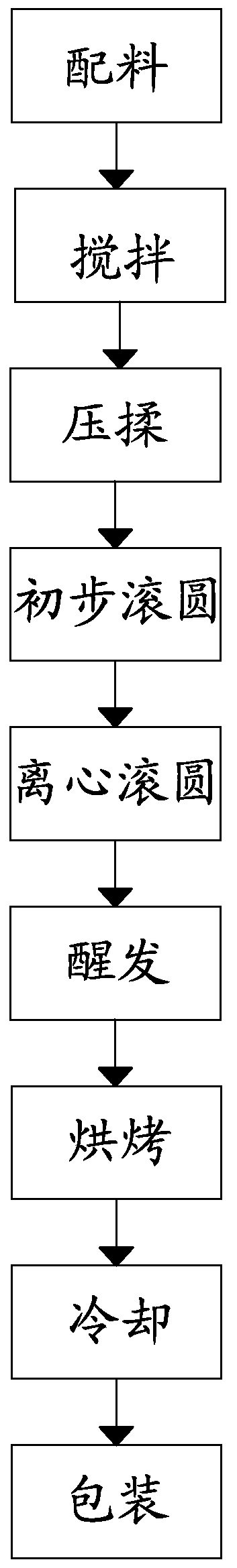

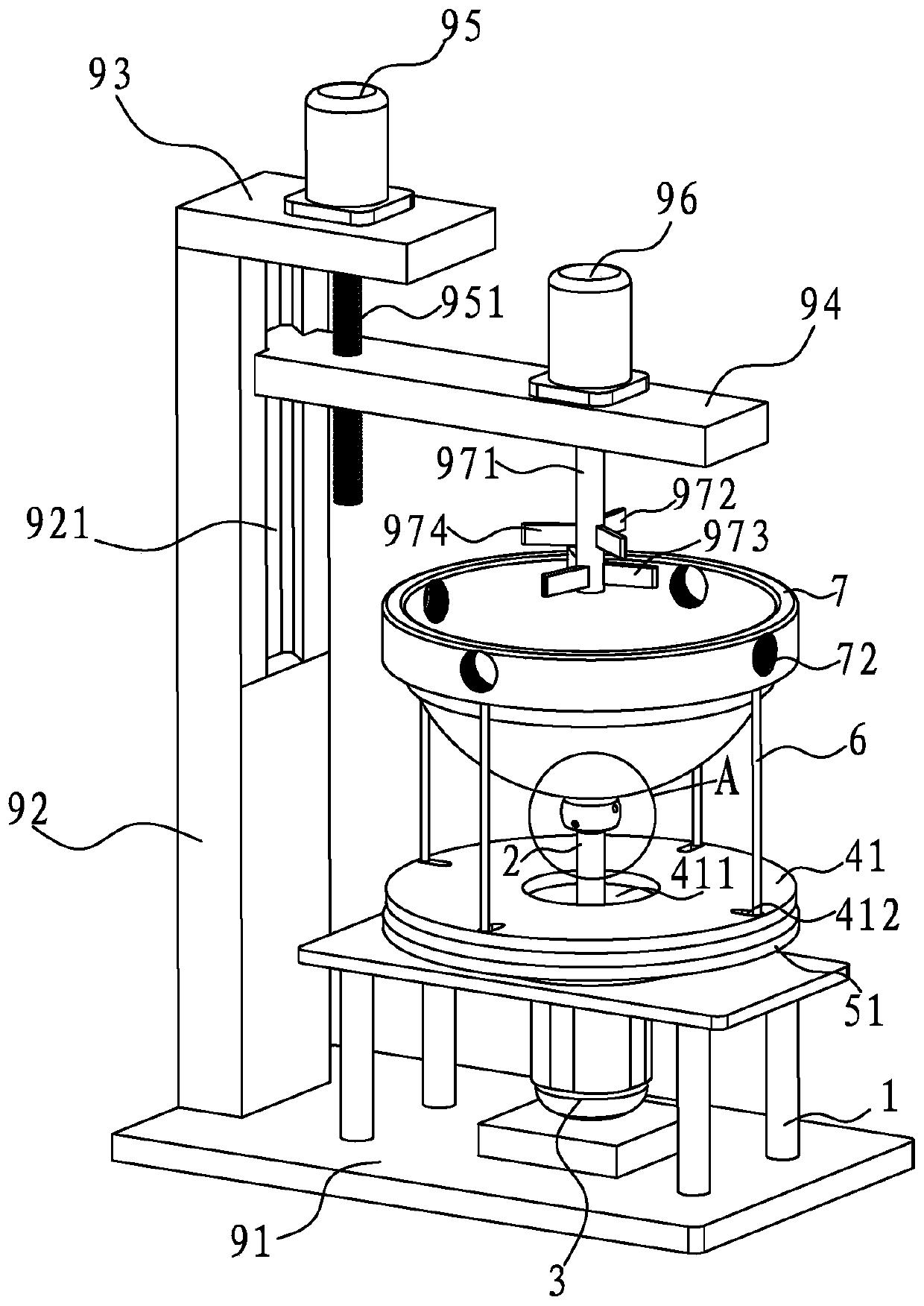

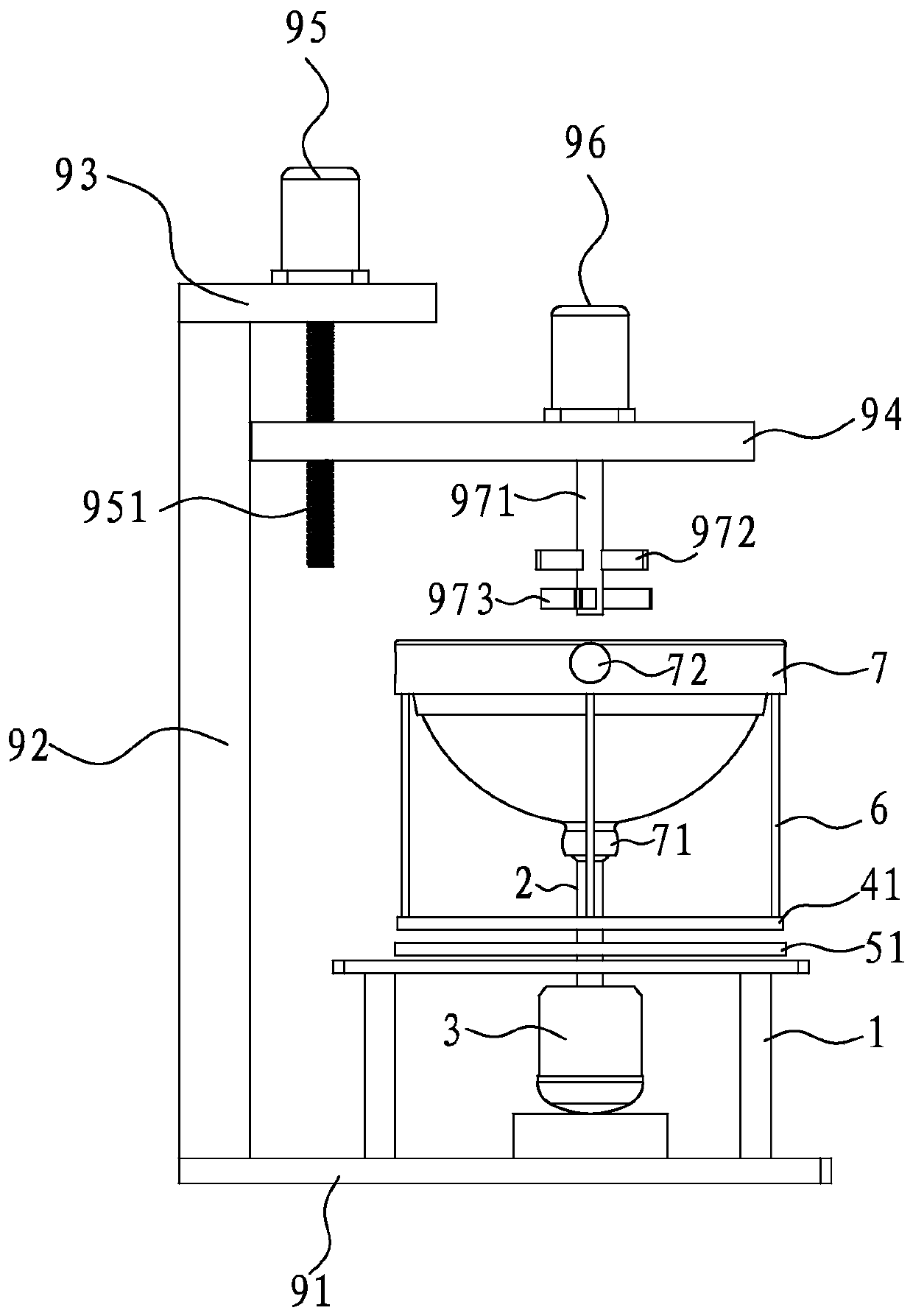

[0059] like Figure 1-11 Shown, a kind of preparation method of fermented bread, wherein, described preparation method comprises the steps:

[0060] (1) Ingredients: Proportionate the bread raw materials.

[0061] (2) Stirring: The raw materials after proportioning are fully stirred in the stirring and rounding device to form a dough.

[0062] (3) Pressing and kneading: the stirred dough is pressed and kneaded in the stirring and rounding device, and then the pressed and kneaded dough is divided into small doughs of suitable size.

[0063] (4) Preliminary rounding: the kneaded small dough is placed in the stirring and rounding device, and the staff alternately applies force to the stirring and rounding device repeatedly, so that the stirring and rounding device is tilted, and then the dough is repeatedly roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com