Milk beverage and preparation method thereof

A technology for milk beverages and raw materials, applied in dairy products, milk preparations, applications, etc., can solve the problems of low viscosity, thin taste, poor consumer drinking experience, etc., and achieve the effect of less viscosity reduction and increased product viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] 1.1 Preparation of fermented milk

[0085] 1) Raw material of fermented milk

[0086] Milk 800kg;

[0087] Sweetener: white granulated sugar 60kg, high fructose syrup 60kg;

[0088] Stabilizer: modified starch 27kg;

[0089] Lactic acid bacteria: Lactobacillus 1*10 8 CFU / g; Streptococcus thermophilus 1*10 8 CFU / g.

[0090] 2) Preparation method of fermented milk

[0091] a) heating the milk to 60°C, adding a stabilizer and a sweetener, and mixing to obtain a mixed material liquid;

[0092] b) Homogenize the mixture liquid, wherein the homogenization pressure is 150 bar, and the homogenization temperature is 55°C;

[0093] c) Sterilize the homogenized feed liquid, the sterilization temperature is 95°C, and the sterilization time is 300s;

[0094] d) cooling the sterilized feed liquid to 43° C., inoculating and fermenting, the acidity at the end of fermentation is 80-85° T, and fermented milk is obtained.

[0095] 2.2 Preparation of finished milk

[0096] 1) Raw...

Embodiment 2

[0111] 2.1 Preparation of fermented milk

[0112] 1) Raw material of fermented milk

[0113] Milk 800kg;

[0114] Sweetener: white granulated sugar 60kg, high fructose syrup 60kg;

[0115] Stabilizer: modified starch 15kg;

[0116] Lactic acid bacteria: Lactobacillus 1*10 8 CFU / g; Streptococcus thermophilus 1*10 8 CFU / g.

[0117] 2) The preparation method of fermented milk is the same as in Example 1.

[0118] 2.2 Preparation of finished milk

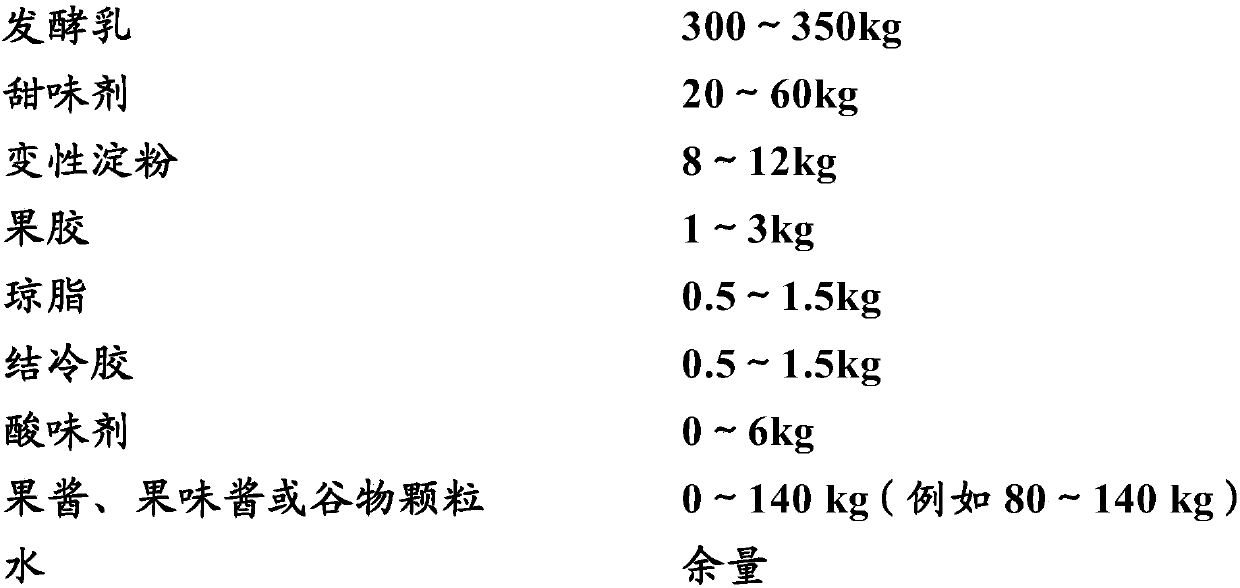

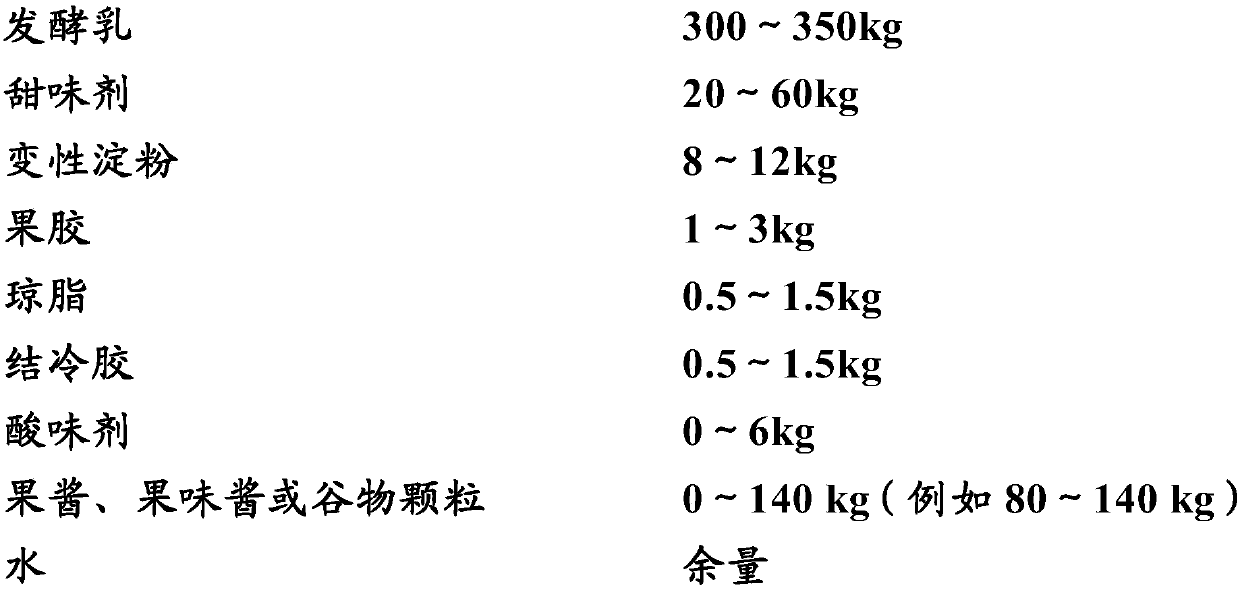

[0119] 1) Raw material of finished milk

[0120] Each 1000kg raw material contains:

[0121] Fermented milk 330kg;

[0122] Sweetener: white granulated sugar 20kg, high fructose syrup 20kg;

[0123] Stabilizer: modified starch 10kg, pectin 2kg, agar 1kg, gellan gum 1kg;

[0124] Jam: compound jam 80-140kg;

[0125] Ingredients water: balance.

[0126] 2) The preparation method of finished milk is the same as in Example 1.

[0127] After testing, the viscosity of the finished milk obtained in Example 2 is 400 cp, and the to...

Embodiment 3

[0129] 2.1 Preparation of fermented milk

[0130] 1) Raw material of fermented milk

[0131] Milk 800kg;

[0132] Sweetener: white granulated sugar 60kg, high fructose syrup 60kg;

[0133] Stabilizer: modified starch 36kg;

[0134] Lactic acid bacteria: Lactobacillus 1*10 8 CFU / g; Streptococcus thermophilus 1*10 8 CFU / g.

[0135] 2) The preparation method of fermented milk is the same as in Example 1.

[0136] 2.2 Preparation of finished milk

[0137] 1) Raw material of finished milk

[0138] Each 1000kg raw material contains:

[0139] Fermented milk 330kg;

[0140] Sweetener: white granulated sugar 20kg, high fructose syrup 20kg;

[0141] Stabilizer: modified starch 10kg, pectin 2kg, agar 1kg, gellan gum 1kg;

[0142] Jam: compound jam 80-140kg;

[0143] Ingredients water: balance.

[0144] 2) The preparation method of finished milk is the same as in Example 1.

[0145] After testing, the viscosity of the finished milk obtained in Example 3 is 1000 cp, and the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com