Camellia oleifera shell and seed separating system

A separation system, the technology of Camellia oleifera husk, which is applied in the direction of solid separation, shelling, filtering, etc., can solve problems such as damage to camellia oleifera seeds, incomplete shelling, and a lot of labor, so as to improve the effect of shelling, improve quality, The effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

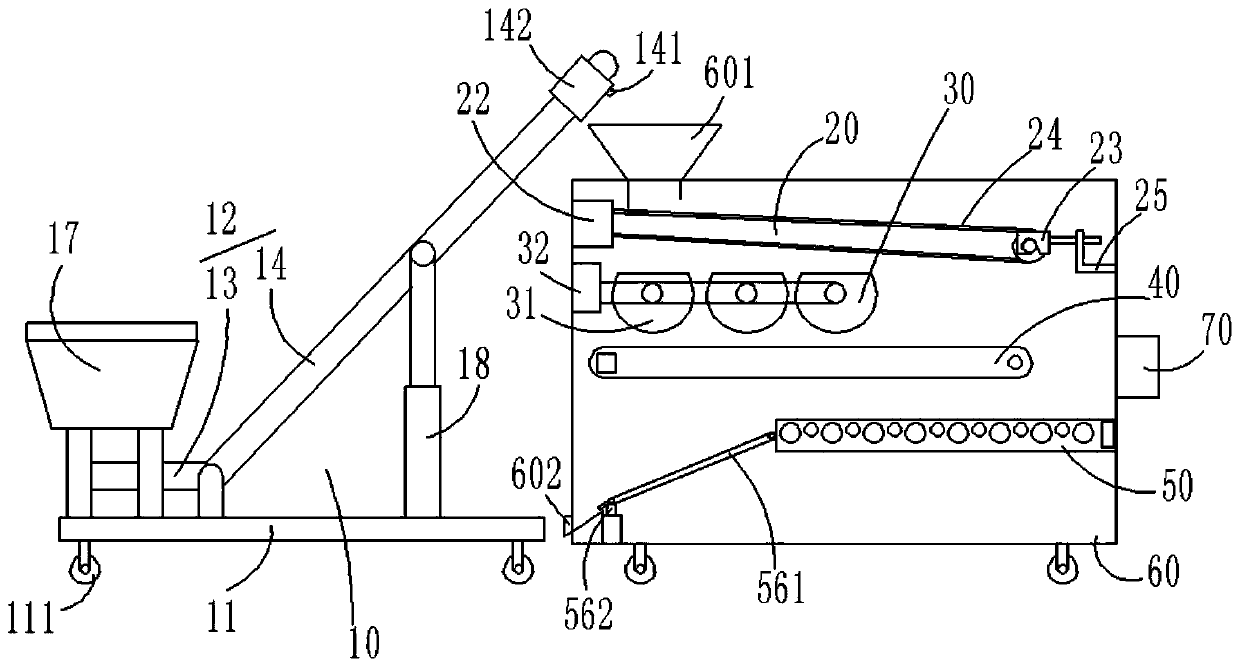

[0059] Working principle of the present invention:

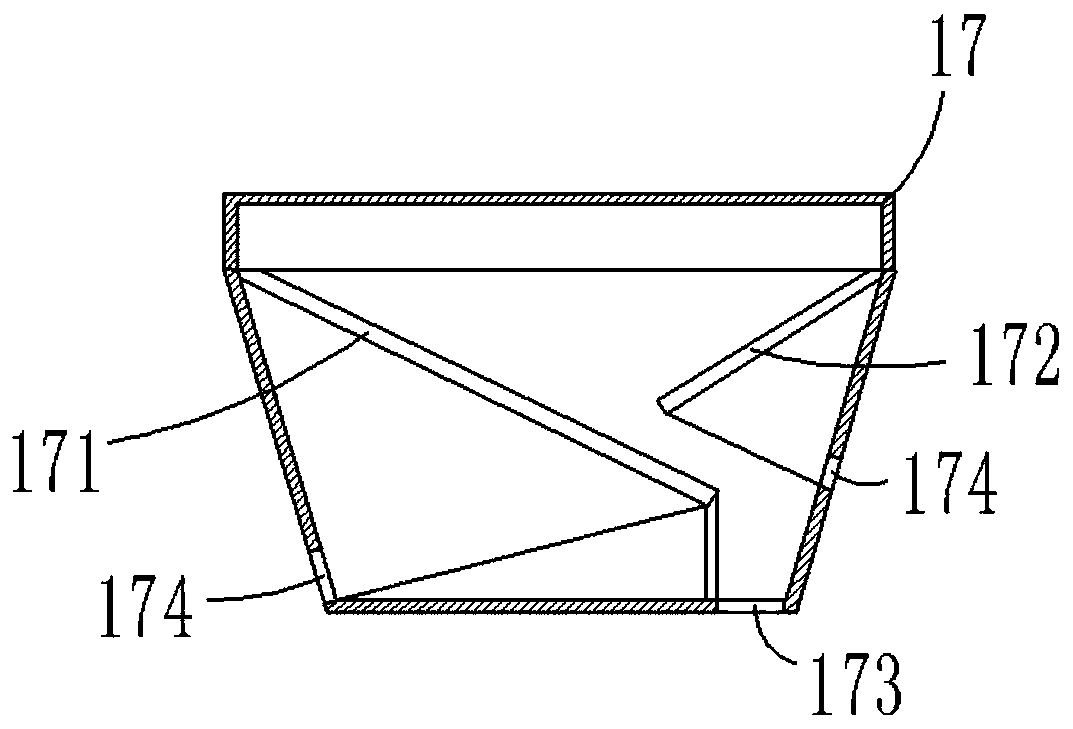

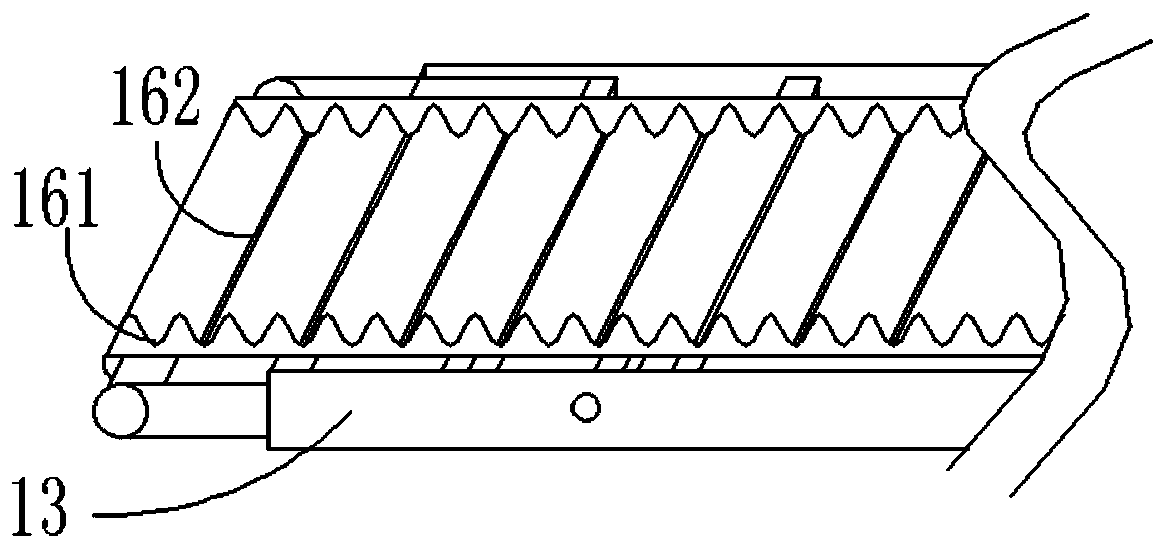

[0060] Put the camellia oleifera fruit into the feeding box 17, first slant plate 171 and second slant plate 172 carry out coarse screening to the camellia oleifera fruit, and filter out the sundries such as small stones brought in from the camellia oleifera fruit and discharge them from the slag discharge hole 174; The Camellia oleifera fruit that screens enters on the transmission belt 16 of conveying mechanism 12 from discharge hole 173; Camellia oleifera is transported to the feed port 601 of the peeling and sorting equipment;

[0061] When one end of the movable transmission part 14 is too high or too low from the feed port 601, the movable transfer part 14 can be rotated along the fixed transfer part 13 by controlling the lifting of the lifting device 18, thereby realizing the connection between the movable transfer part 14 and the feed port 601. The adjustment of the distance between the conveying device 10 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com