A kind of co-scr denitrification catalyst and its preparation method and application

A CO-SCR and denitrification catalyst technology, applied in the field of industrial catalysis, can solve the problems of low NOx removal efficiency, achieve the effect of improving poisoning effect, uniform microstructure distribution, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] The third embodiment of the present invention provides an application of the above-mentioned CO-SCR denitration catalyst in flue gas treatment.

[0039] In one or more examples of this embodiment, the flue gas contains water vapor and oxygen.

[0040] In order to enable those skilled in the art to understand the technical solution of the present invention more clearly, the technical solution of the present invention will be described in detail below in conjunction with specific examples and comparative examples.

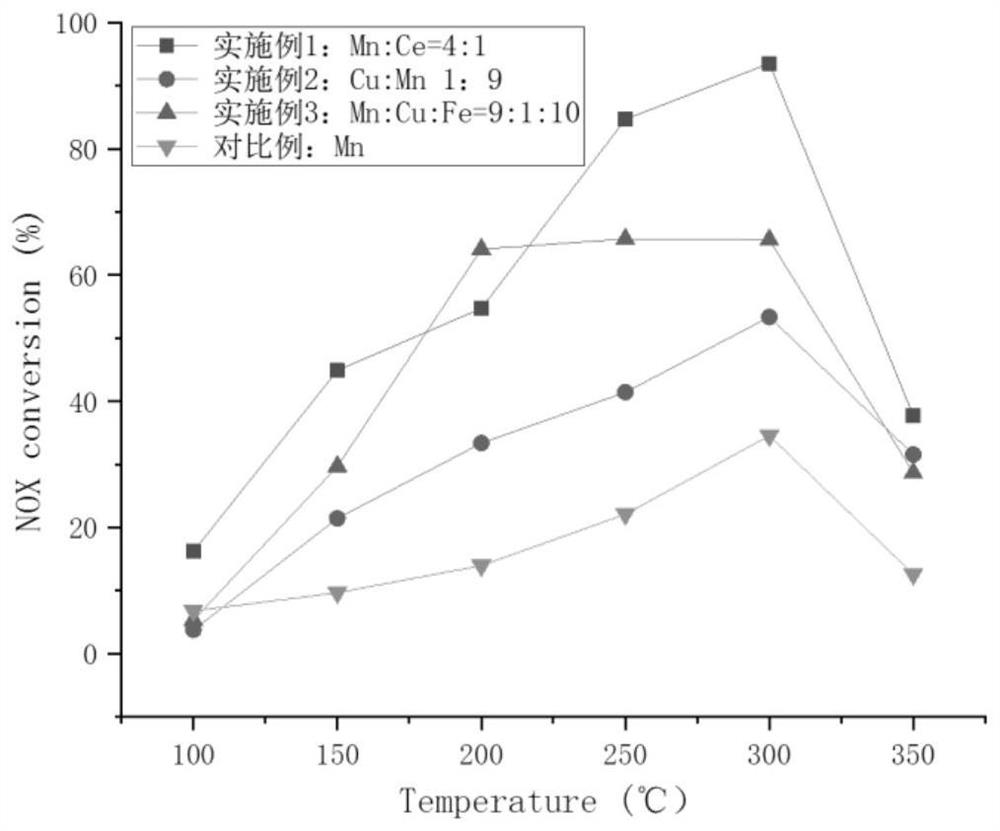

Embodiment 1

[0042] Weigh cerium ammonium nitrate (Ce(NH 4 ) 2 (NO 3 ) 6 ) 15.81g, 50wt% manganese nitrate aqueous solution (Mn(NO 3 ) 2 50wt%H 2 O) 41.3g was added into deionized water to dissolve according to the ratio of Mn:Ce=4:1, and then stirred at 70°C for 60min to obtain mixed salt solution A. Weigh a certain amount of Na 2 CO 3 Dissolved in deionized water to make alkaline precipitant Na 2 CO 3 solution. Under the condition of stirring at 40°C, Na 2 CO 3 Alkaline precipitating agent and stirring until the pH of the mixed solution = 8 to obtain a mixture C. The mixture C was aged at room temperature for 2 h, then filtered and washed repeatedly with deionized water until the pH of the filtrate was 7, and the filter cake D was obtained. The filter cake D was placed in a ball mill for 120 min at a speed of 420 r / min to obtain powder E. The powder E was dried in an oven at 110° C. for 12 hours, and finally calcined and activated in a muffle furnace at 500° C. for 5 hours ...

Embodiment 2

[0044] Weigh copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) 9.462g, 50wt% manganese nitrate aqueous solution (Mn(NO 3 ) 2 50wt%H 2 O) 126.152g was added into deionized water to dissolve in the ratio of Mn:Cu=9:1, and then stirred at 70°C for 60min to obtain mixed salt solution A. Weigh a certain amount of Na 2 CO 3 Dissolved in deionized water to make alkaline precipitant Na 2 CO 3 solution. Under the condition of stirring at 40°C, Na 2 CO 3 Alkaline precipitating agent and stirring until the pH of the mixed solution = 8 to obtain a mixture C. The mixture C was aged at room temperature for 2 h, then filtered and washed repeatedly with deionized water until the pH of the filtrate was 7, and the filter cake D was obtained. The filter cake D was placed in a ball mill for 120 min at a speed of 420 r / min to obtain powder E. The powder E was dried in an oven at 110° C. for 12 hours, and finally calcined and activated in a muffle furnace at 500° C. for 5 hours to prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com