A kind of flue gas sncr denitrification agent and preparation method thereof

A denitration agent and flue gas technology, applied in the field of flue gas SNCR denitrification agent and its preparation, can solve the problems of unstable temperature range of high temperature flue gas, increase of pollutants, poor effect of denitrification agent, etc., and achieve corrosion resistance of reaction equipment Small size, reduced reaction temperature, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

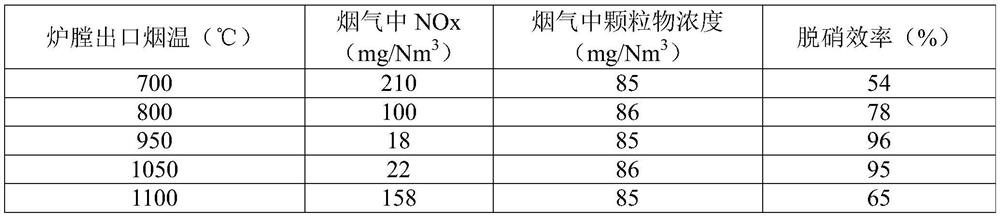

Embodiment 1

[0024] Preparation of denitrification agent:

[0025] Weigh 1 part of nano-titanium powder with particle size of 10-100nm, 100 parts of activated carbon and 8000 parts of urea, place the nano-titanium powder in an airtight container, fill the airtight container with hydrogen, and let stand for 10 minutes to obtain a hydrogenated storage tank. hydrogen metal;

[0026] The hydrogen storage metal and activated carbon powder after hydrogenation are mixed and stirred in a mixer, the stirring speed is 50r / min, and the first mixture is obtained by stirring for 5 minutes, and then the first mixture and urea are put into the mixer for mixing and stirring, and the stirring speed is 100r / min, stirring for 10min to obtain flue gas SNCR denitration agent.

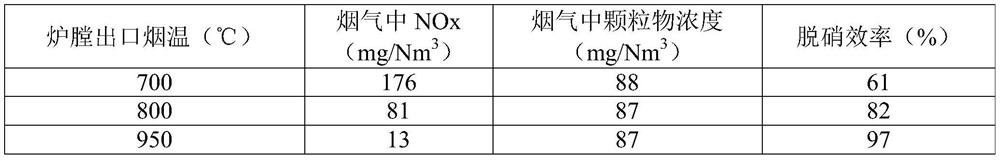

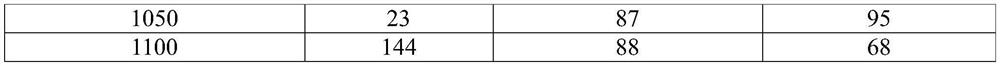

Embodiment 2

[0028] Preparation of denitrification agent:

[0029] Weigh 20 parts of nano-magnesium powder with a particle size of 10-100nm, 500 parts of activated carbon and 9,500 parts of ammonium carbonate, place the nano-magnesium powder in an airtight container, fill the airtight container with hydrogen, and let stand for 30min to obtain a hydrogenated hydrogen storage metal;

[0030] The hydrogen storage metal and activated carbon powder after hydrogenation are mixed and stirred in a mixer, and the stirring speed is 100 r / min, and the first mixture is obtained by stirring for 10 minutes, and then the first mixture and ammonium carbonate are put into the mixer for mixing and stirring, and the stirring speed is 200r / min, stirring for 20min to obtain flue gas SNCR denitration agent.

Embodiment 3

[0032] Preparation of denitrification agent:

[0033] Weigh 10 parts of nano-zirconium powder with a particle size of 10-100nm, 200 parts of activated carbon, 4,500 parts of urea and 4,500 parts of ammonium bicarbonate, place the nano-zirconium powder in an airtight container, fill the airtight container with hydrogen, and keep the airtight container. The internal pressure was 100 atm, and it was allowed to stand for 10 minutes to obtain the hydrogen storage metal after hydrogenation;

[0034] The hydrogen storage metal after hydrogenation and the activated carbon powder are mixed and stirred in a mixer, the stirring speed is 80r / min, and the first mixture is obtained by stirring for 80min, and then the first mixture, urea and ammonium bicarbonate are put into the mixer for mixing and stirring, The stirring speed was 150 r / min, and the stirring was carried out for 15 min to obtain the flue gas SNCR denitration agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com