Automatic control system and method for condensate polishing mixed bed

A technology of condensate fine treatment and automatic control system, which is applied in non-polluted water treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Avoiding problems such as large ammonia water consumption, avoiding too short water production cycle, prolonging the running time of the mixed bed, and achieving high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

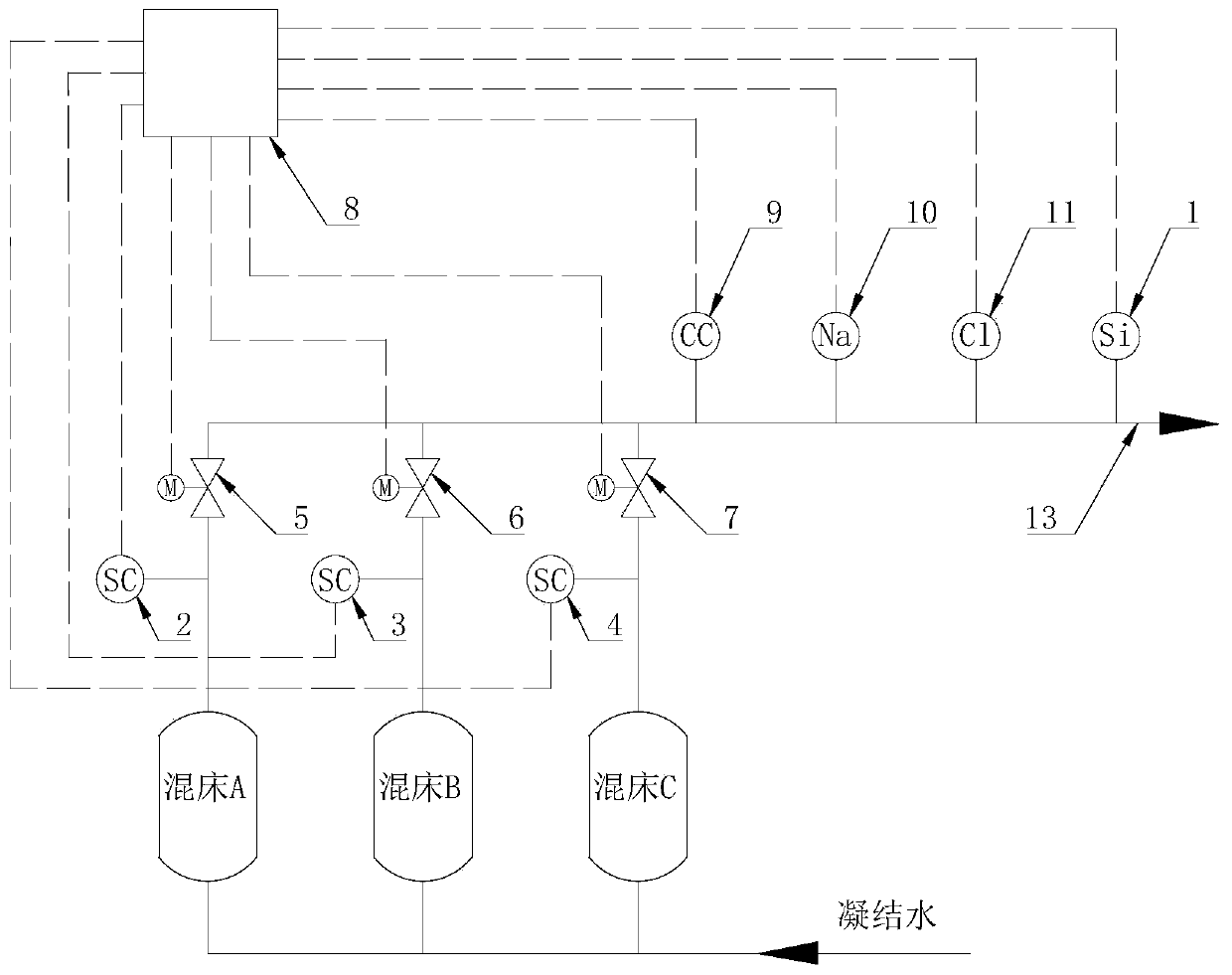

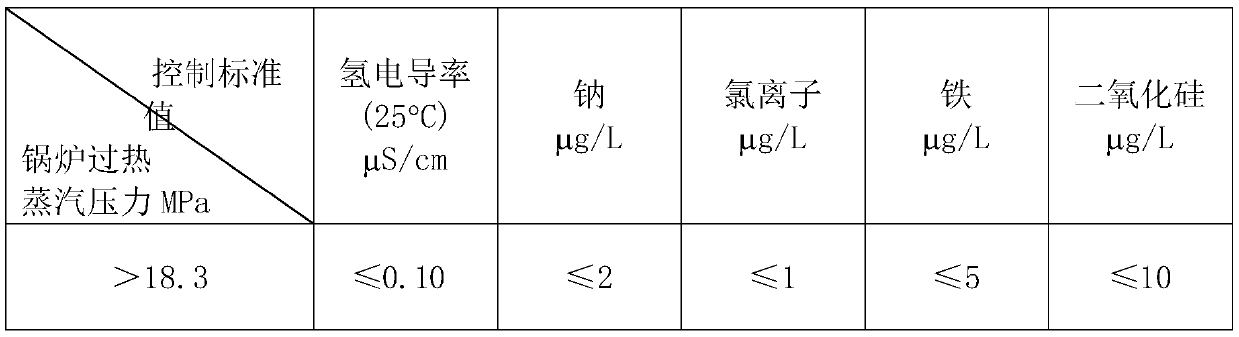

[0019] Such as figure 1 As shown, the present invention relates to a mixed bed automatic control system for condensate polishing, including an online hydrogen conductivity meter 9, an online sodium meter 10, an online chlorine meter 11 and an online silicon meter 1 arranged on the mixed bed main pipe 13 pipelines , the mixed bed A outlet online conductivity meter 2 and the mixed bed A outlet electric valve 5 set on the mixed bed A outlet pipeline, the mixed bed B outlet online conductivity meter 3 and the mixed bed B outlet installed on the mixed bed B outlet pipeline An electric outlet valve 6, an online conductivity meter 4 at the outlet of the mixed bed C and an electric valve 7 at the outlet of the mixed bed C are set on the outlet pipeline of the mixed bed C. On-line hydrogen conductivity meter 9, on-line sodium meter 10, on-line chlorine meter 11 and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com