Anti-rust mark automatic metal pipe necking machine

A metal pipe, metal pipe technology, applied in metal processing equipment, grinding machines, grinding/polishing equipment, etc., can solve the problems of falling off and extrusion, metal pipe surface bumping, surface depression, etc., to improve flatness, Improve the quality and avoid the effect of bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

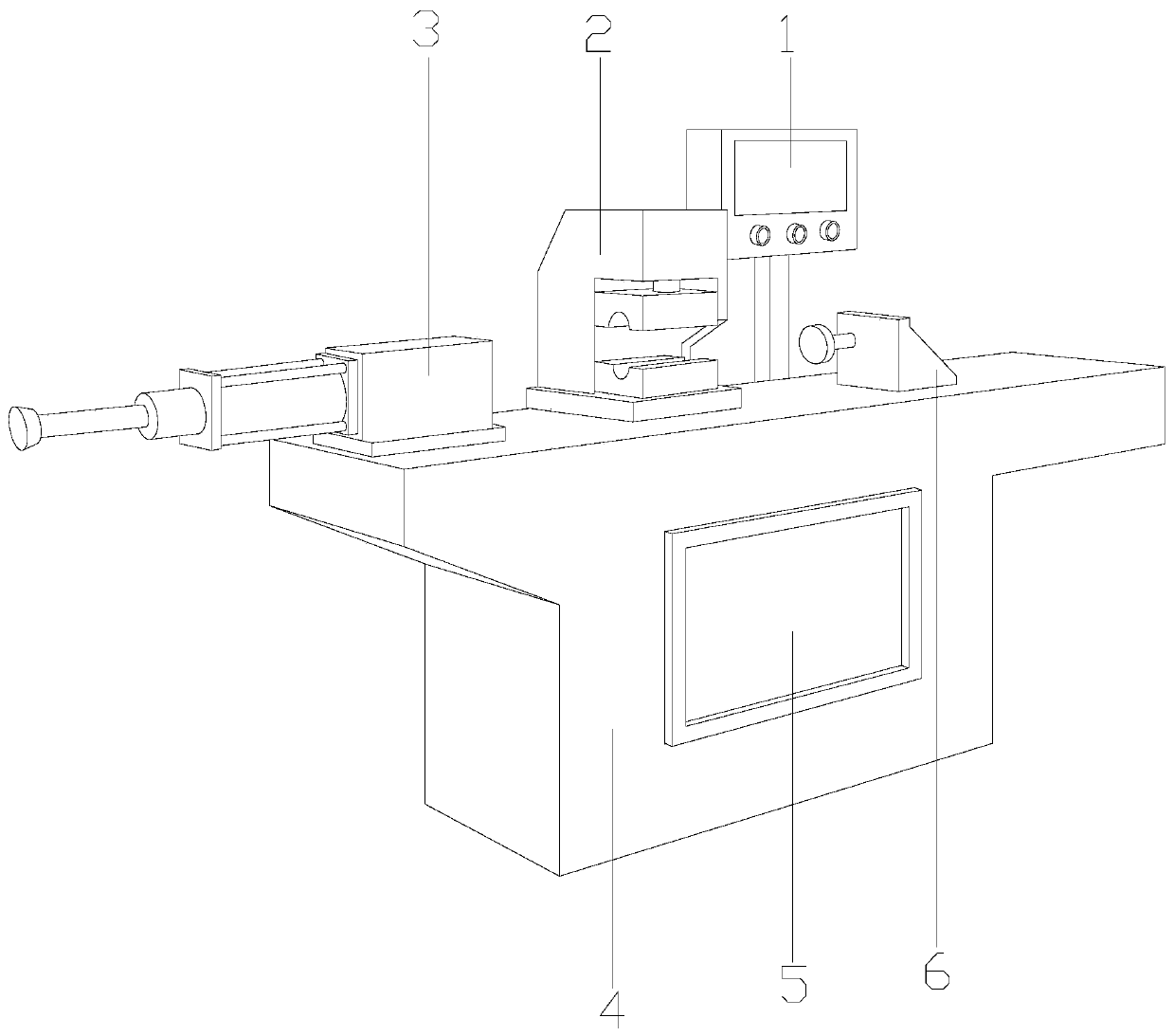

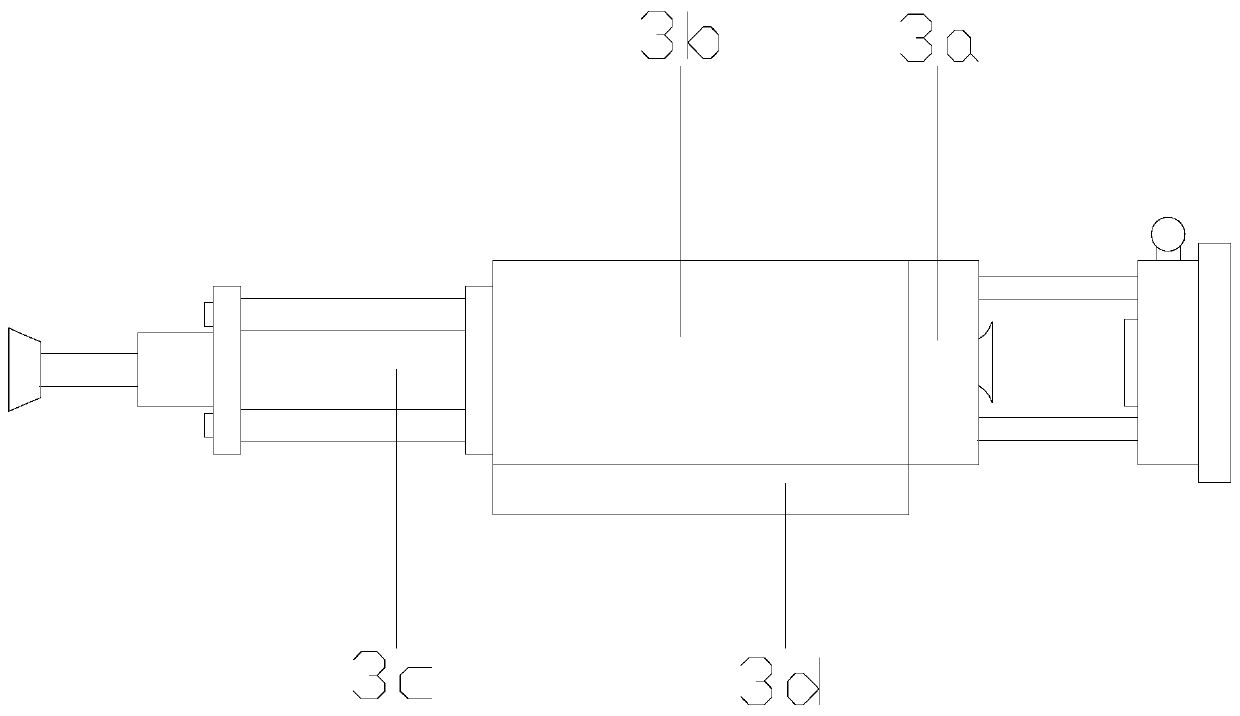

[0024] see Figure 1-Figure 5, the present invention provides an anti-rust metal pipe automatic shrinking machine, its structure includes an intelligent controller 1, a metal pipe compression structure 2, a hydraulic compression port device 3, an equipment support platform 4, a heat dissipation inspection port 5, a metal pipe The support plate 4 is installed horizontally on the floor of the workshop, the heat dissipation inspection port 5 is nested in the middle of the front of the equipment support platform 4, and the metal tube pressing structure 2 is vertically installed on the equipment support platform 4 In the middle of the surface, the hydraulic pressure port device 3 is located at the leftmost end of the upper surface of the metal tube compression structure 2, the intelligent controller 1 and the equipment support platform 4 are fixed by bolts and electrically connected, and the metal tube backing plate 6 is connected to the equipment The support table 4 adopts a clear...

Embodiment 2

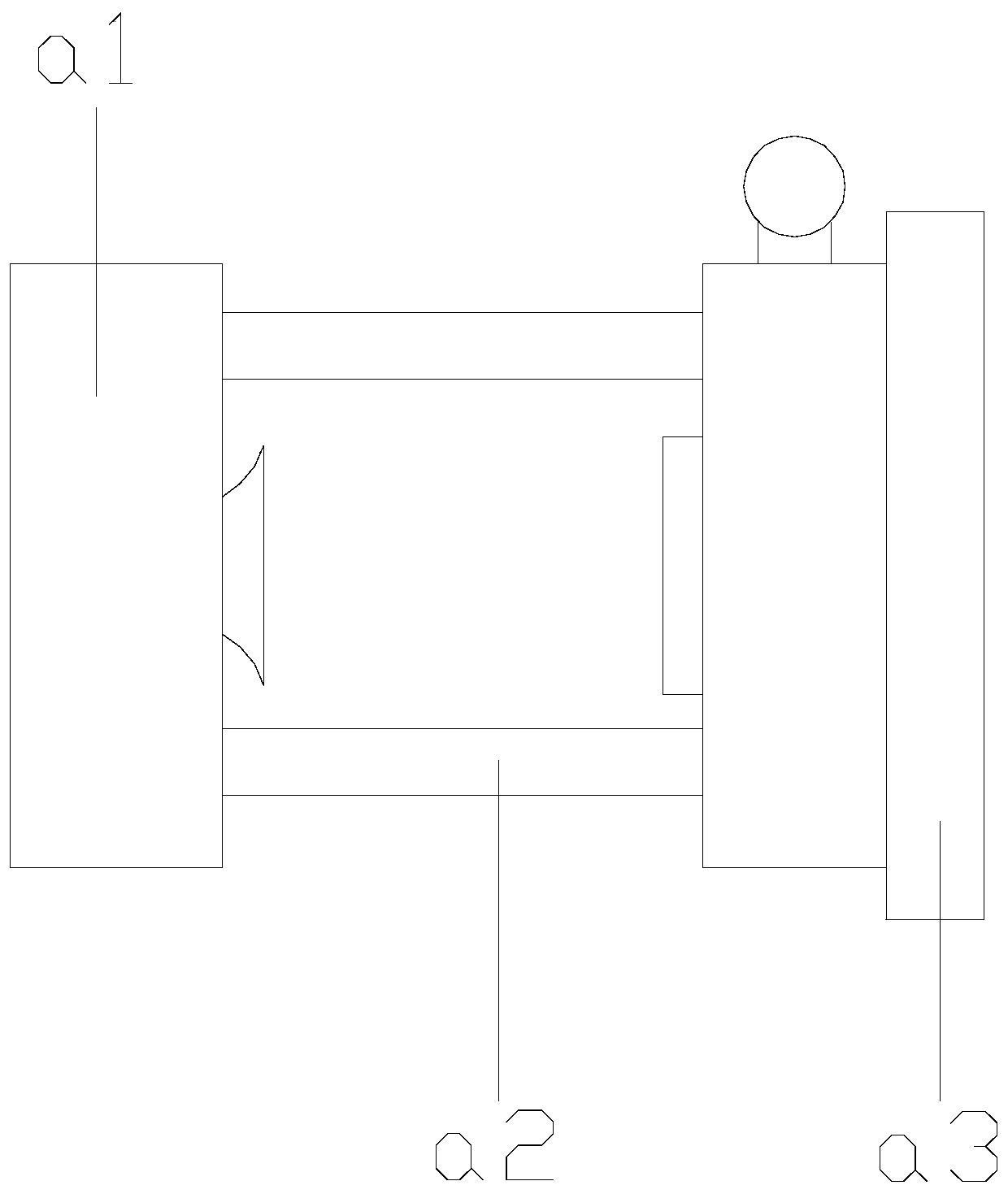

[0027] see Figure 6-Figure 7 , the pipe taking mechanism a3 is composed of a rotating buckling block a31, a driving ring frame a32, a traction guide rail a33, and an inertial pipe taking device a34. The rotating buckling block a31 is nested inside the driving rod fixing frame a23. The ring frame a32 and the rotating fastening block a31 adopt a clearance fit, the traction guide rail a33 is nested inside the driving ring frame a32, and the inertial pipe taker a34 is fastened with the drive rod fixing frame a23 and attached to the inner wall of the traction guide rail a33 Together, the traction guide rails a33 adopt an eccentric arc. The inertial tube fetcher a34 is composed of a self-returning spring 341, a tube fetching push rod 342, an indexing claw 343, a driving slide bar 344, and a tube fetcher cover 345. The tube fetcher cover 345 is a hollow cylinder structure and The driving rod fixing frame a23 is buckled, the indexing claw 343 is installed on the inner bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com