Thin-walled cylinder part automatic internal supporting clamp and clamping method

A technology of inner support fixtures and thin-walled cylinders, which is applied in the direction of expanding the mandrel, etc., can solve the problem of low support rigidity of arc-shaped plates, difficulty in meeting the high-precision and high-efficiency manufacturing requirements of thin-walled parts, and the inability to guarantee the local rigidity of the processing area of thin-walled parts and other problems, to achieve the effect of light weight, simple structure and reliable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

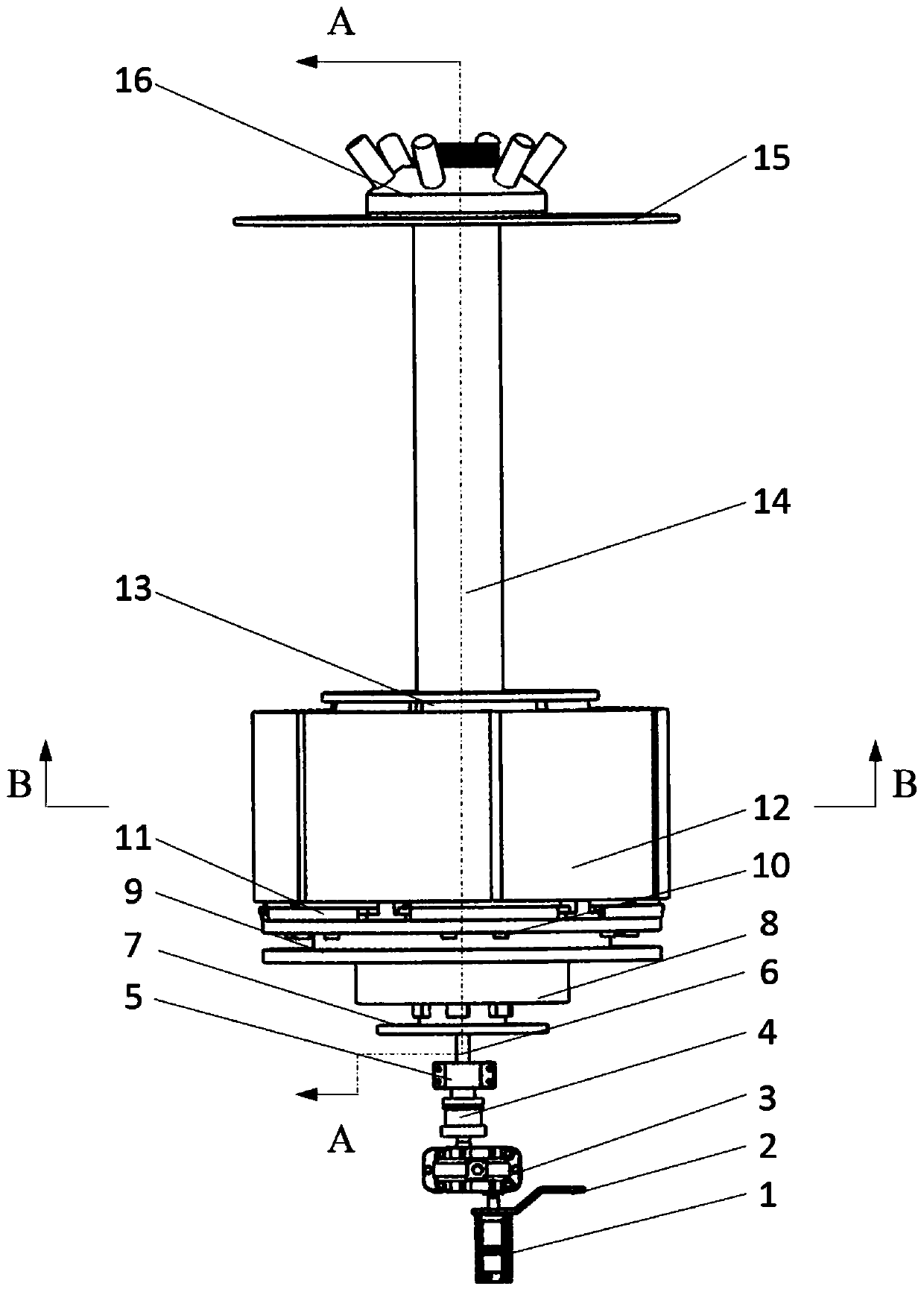

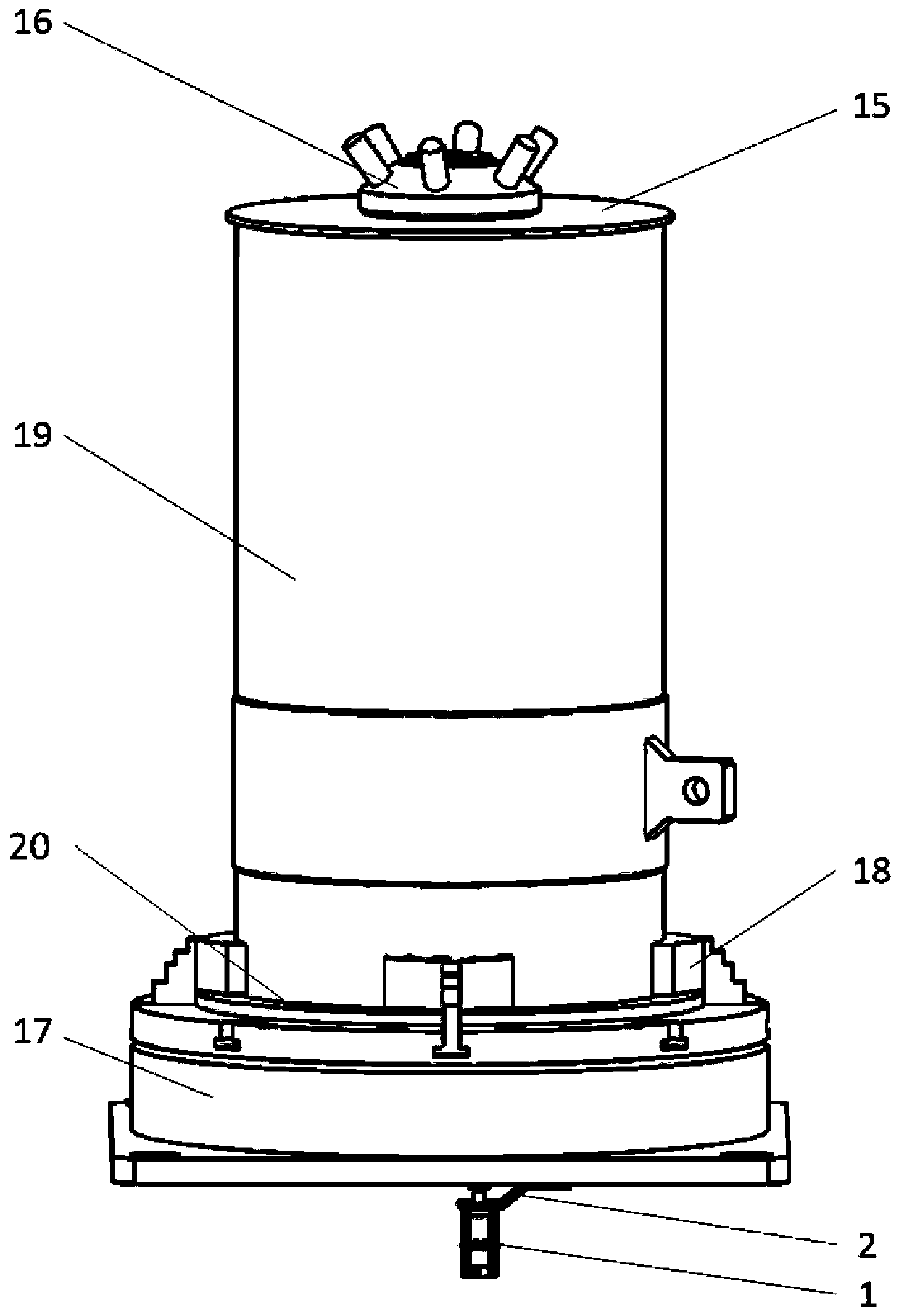

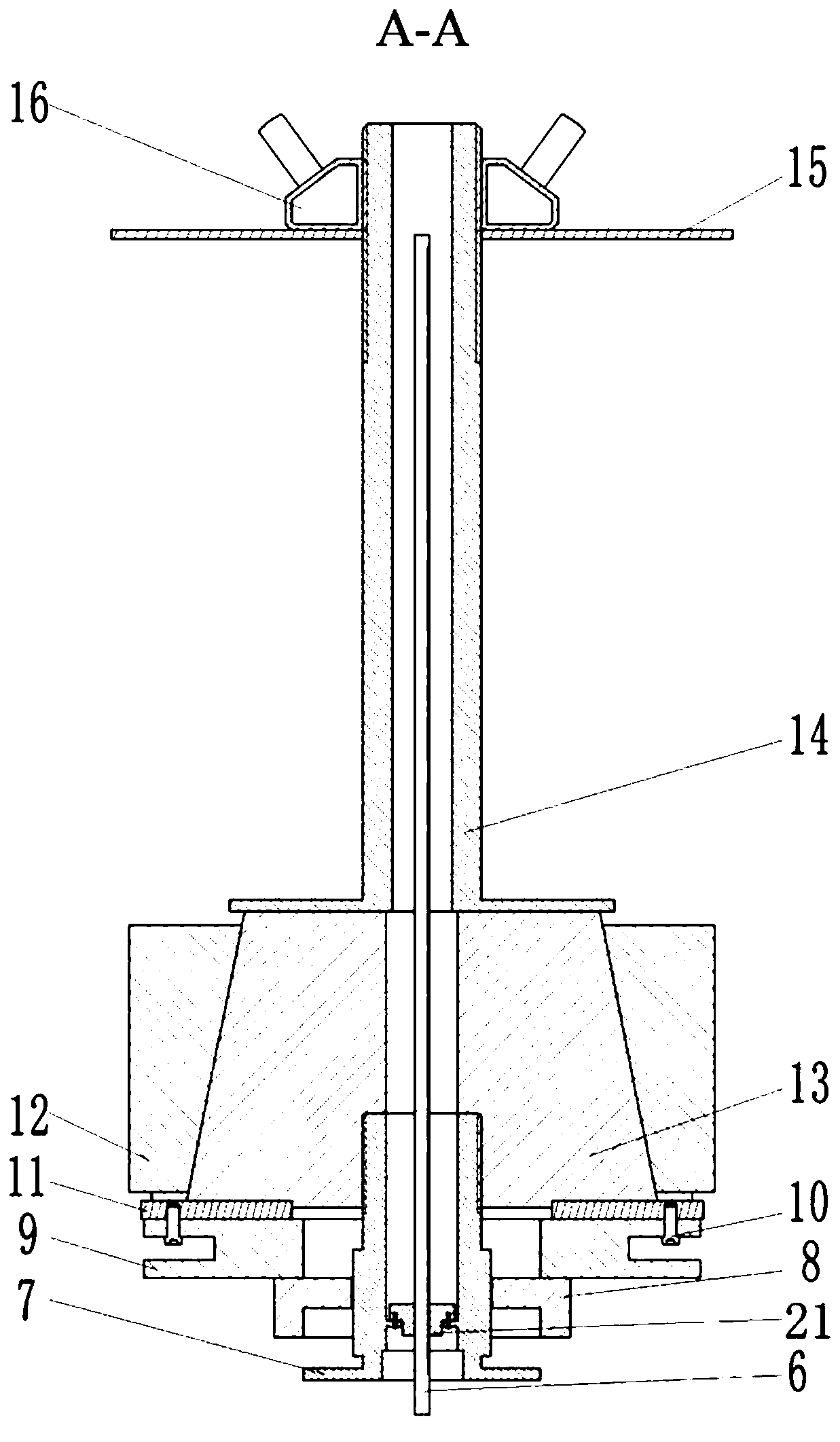

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0017] In the embodiment, the thin-walled cylindrical part 19 is integrally formed by spinning, the material is high-strength steel, the diameter is 1000 mm, the height is 2000 mm, and the wall thickness of the blank is 8-12 mm.

[0018] First, assemble the automatic inner support fixture equipment, see attached figure 1 , attached figure 2 , attached image 3 . The fixture is composed of a power drive system, a positioning clamping device and an auxiliary device. During installation, the servo motor 1 is connected to the input shaft end of the reducer 3 through the mounting plate 2, the output shaft of the reducer 3 is connected to one end of the clutch brake 4, and the other end of the clutch brake 4 is connected to the ball screw 6 through the bearing seat 5 , so that the servo motor 1 effectively drives the ball screw 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com