Manual clamping and intelligent welding workstation of mine belt type feeder striker plate assembly

A baffle and feeder technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as poor interchangeability, misalignment of holes and holes, and poor workpiece accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

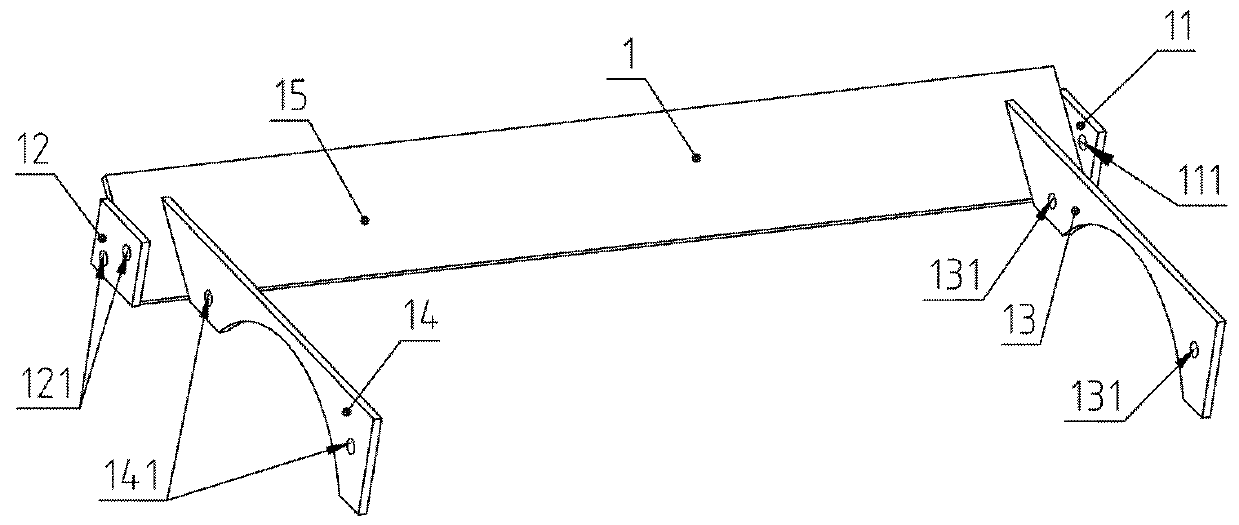

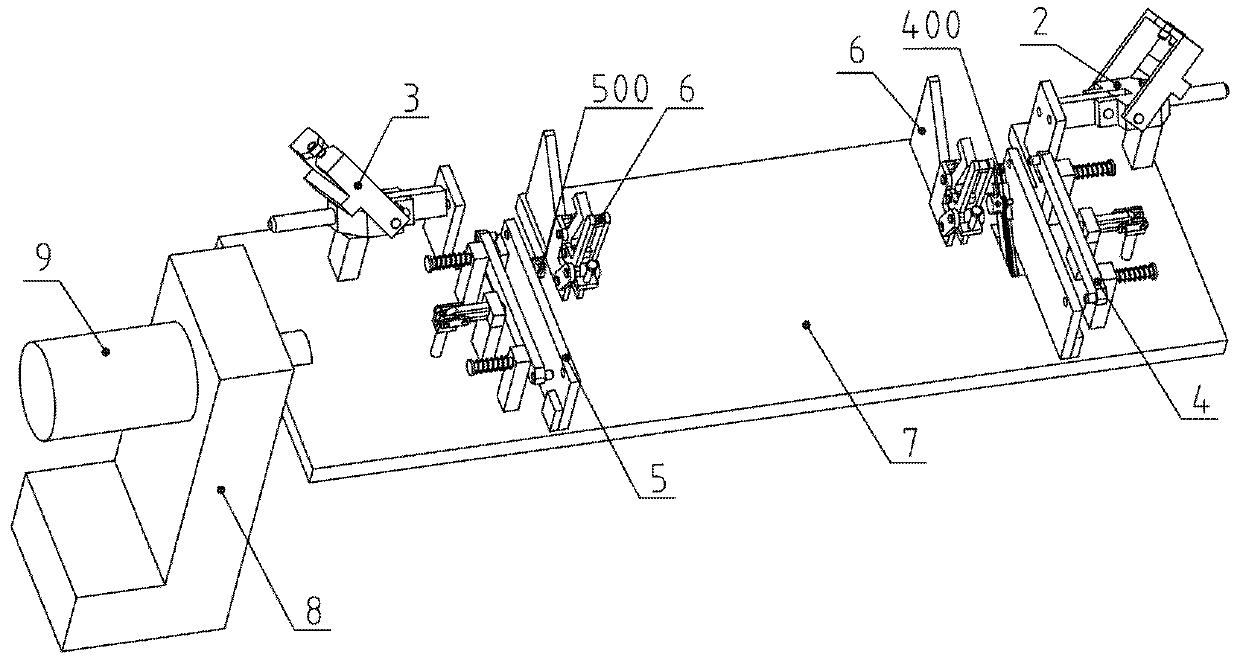

[0050] Example: see Figure 1 to Figure 22 .

[0051] An intelligent welding workstation for manual clamping of the baffle plate assembly of a mine belt feeder, including a welding robot, a left flange clamping assembly 2, a right flange clamping assembly 3, a left arc plate clamping assembly 4, and a left retreating assembly. Die assembly 400, right arc plate clamping assembly 5, right ejection mold assembly 500, baffle plate clamping assembly 6, flap 7, fixing seat 8 and servo motor 9; fixing seat 8 and welding robot are respectively fixed to the floor connection;

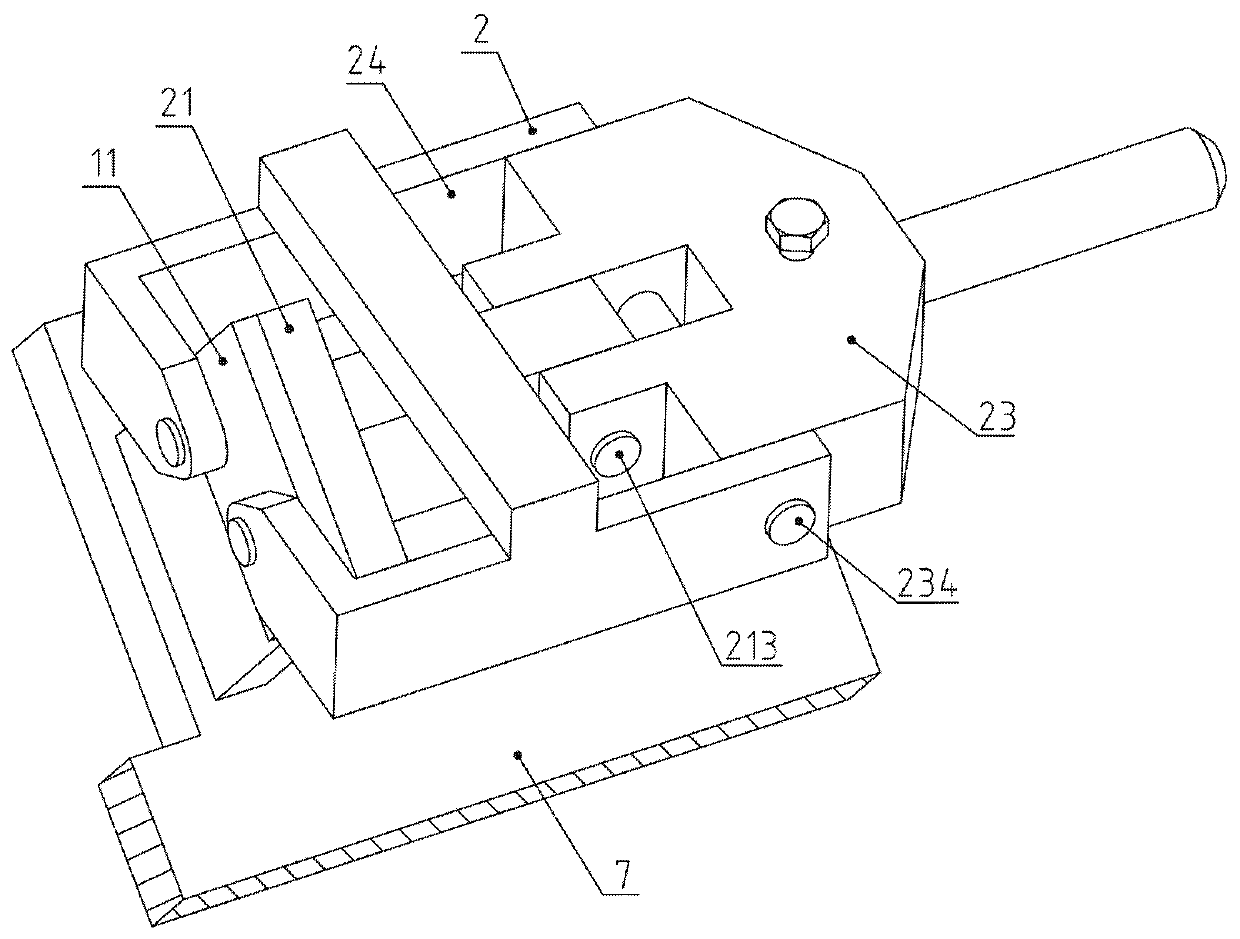

[0052] The left flange clamping assembly 2 includes a left flange fixing seat 21, a left flange positioning seat 22, a left flange crank handle 23 and a left flange tensioning frame 24; a left flange fixing seat 21 and a left flange positioning seat 22 They are respectively fixedly connected with the flap 7; the left flange fixing seat 21 is provided with a left flange positioning surface 211, and two left flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com