Forming method of solid rocket motor case

An engine casing and molding method technology, which is applied in the furnace type, heating/cooling equipment, furnace and other directions, can solve the problems of the thickness of the wall of the engine casing, affecting the coordination between the projectile and the carrier, and increasing the weight of the projectile. High accuracy of housing shape and position tolerance, avoiding the effect of low material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

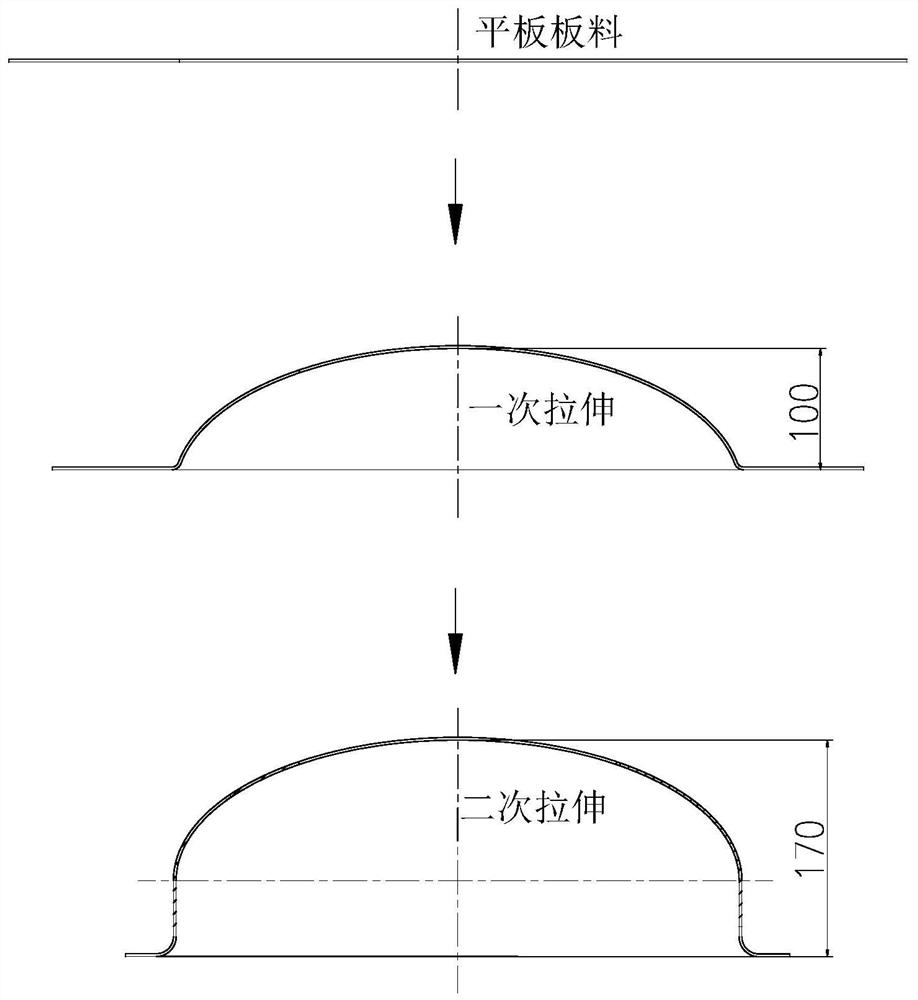

Method used

Image

Examples

Embodiment 1

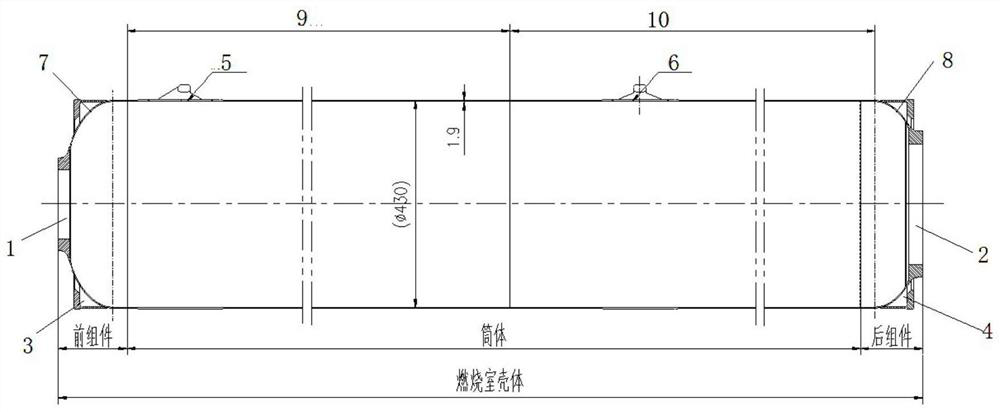

[0087] This example discloses a preparation process for a solid motor casing with a specific size. Its external dimensions are ¢430mm×3050mm, and the wall thickness of the cylinder section is 1.9mm. The specific preparation process is as follows:

[0088] 1) Blank forging and machining;

[0089] Open-hole forging is adopted for bar stock. The specific open-hole forging process includes firstly punching ¢90mm in the center of the bar stock, and then forging and rolling into required ring parts. The starting forging temperature is 1030°C, and the final forging temperature is 850°C. Then rolled into a ring with a wall thickness of 7.5 mm, the solution heat treatment of the ring is twice, the first solution heat treatment temperature is 930 ° C, the heat preservation T1 = 55 min, the second solution heat treatment temperature is 830 ° C, Insulation T2 = 60min;

[0090] Then the ring parts are processed into front joints, rear joints, front skirts, rear skirts, front sliders and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com