Glass edge grinding machine with chamfering and edge grinding functions and glass chamfering method

A technology of edging machine and edging mechanism, which is applied in the direction of machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., which can solve the problem of unstable quality of glass edging and chamfering and large space occupied by equipment and other issues, to achieve the effect of facilitating large-scale assembly line production, reducing procurement costs, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and embodiments.

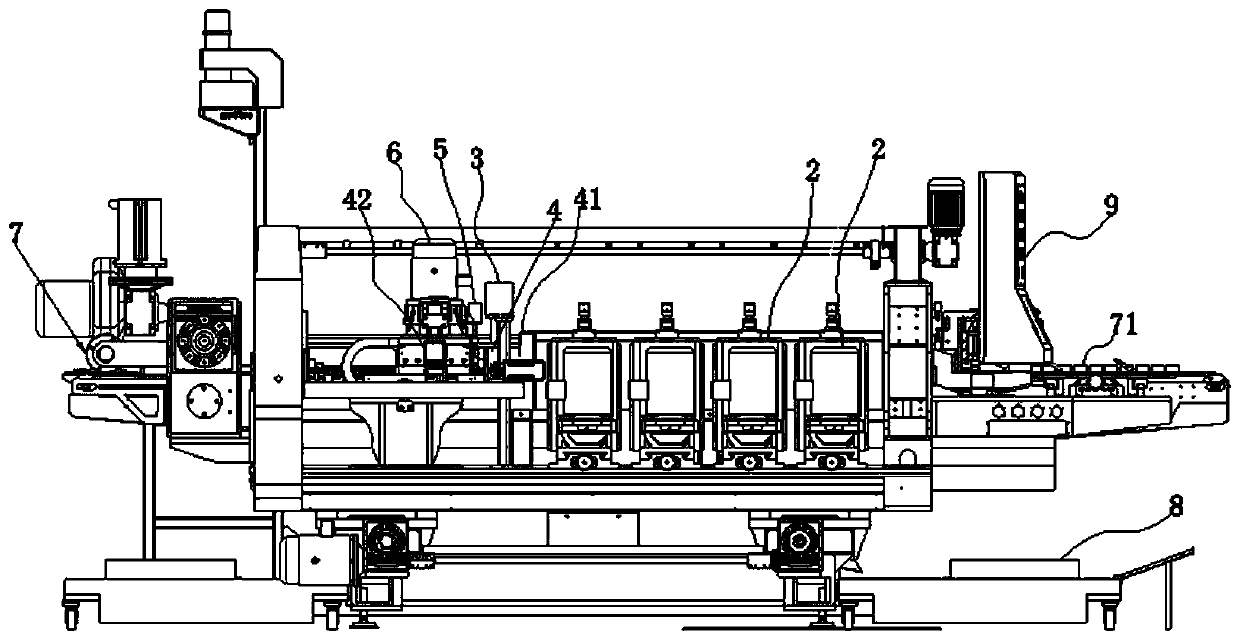

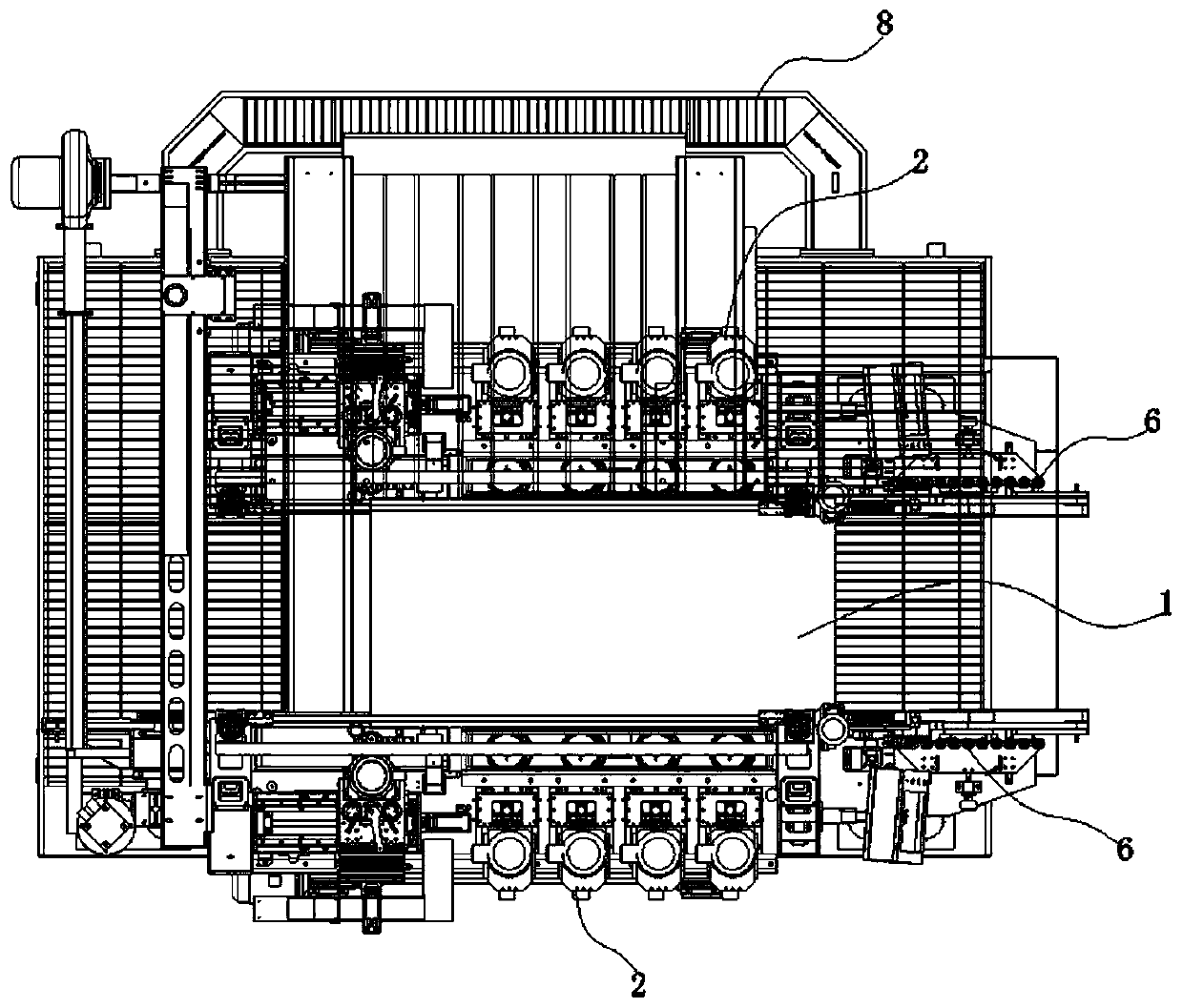

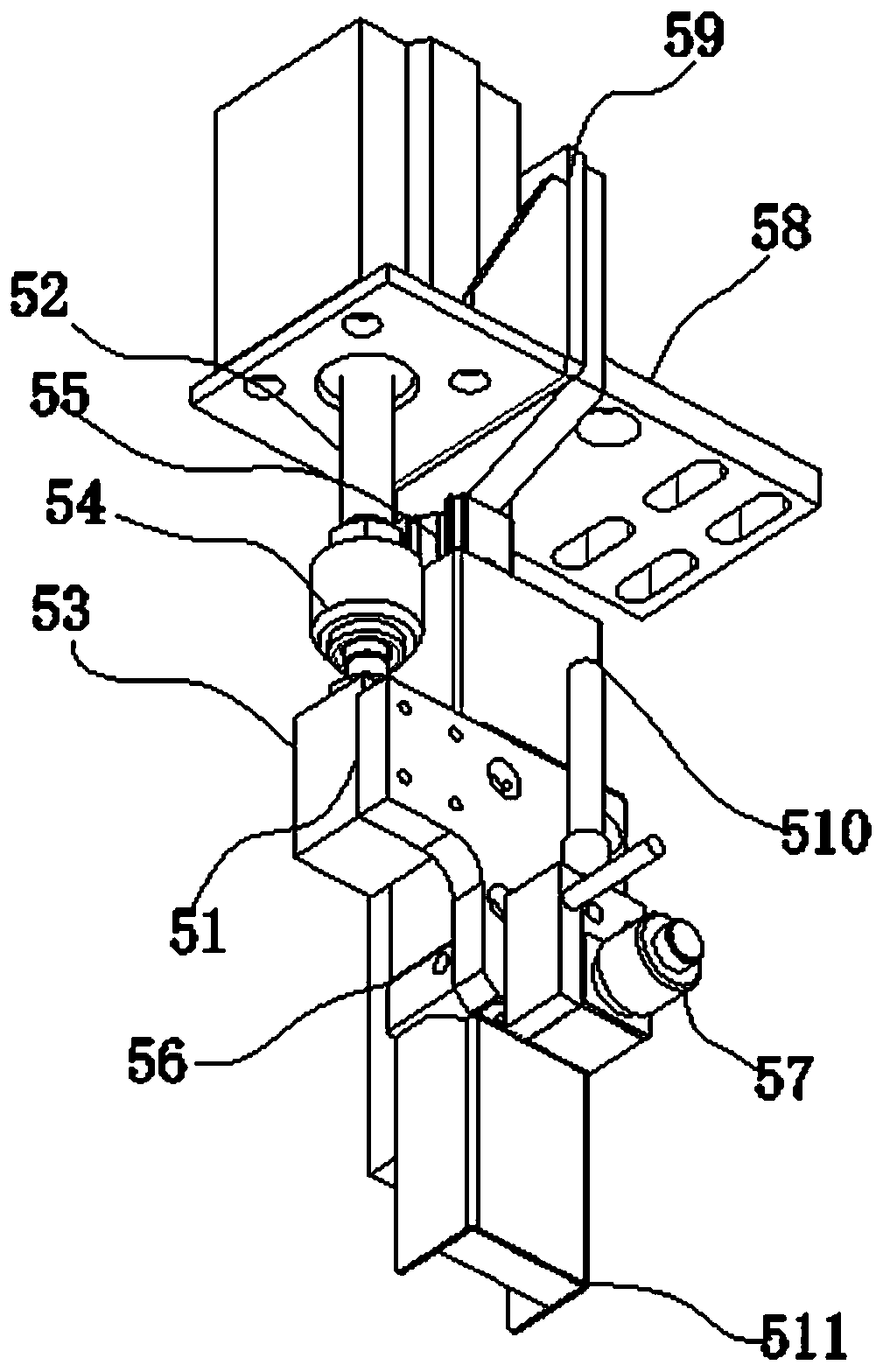

[0034] Such as figure 1 , figure 2 The illustrated glass edging machine with chamfering and edging includes a conveying mechanism 7 and a processing platform provided with an edging mechanism 2. The conveying mechanism 7 is used to convey glass to the processing platform and make The glass is edging by the edging mechanism 2, characterized in that: the processing platform is provided with a detection mechanism, a tool setting mechanism 5, a chamfering grinding head mechanism 6, and a motion control mechanism 4, wherein:

[0035] The detection mechanism 3 is configured to detect the current position of the glass within a preset detection range, so that the knife setting mechanism 5 completes the knife setting operation according to the current position of the glass;

[0036] The chamfering grinding head mechanism 6 is used to chamfer the corners of the glass;

[0037] The m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap