Self-inflating constant-pressure tire burst prevention system

A blow-flat and self-inflating technology, applied in the field of machinery, can solve problems such as blow-out accidents, and achieve the effects of not occupying space, avoiding blow-out accidents, and ensuring life safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

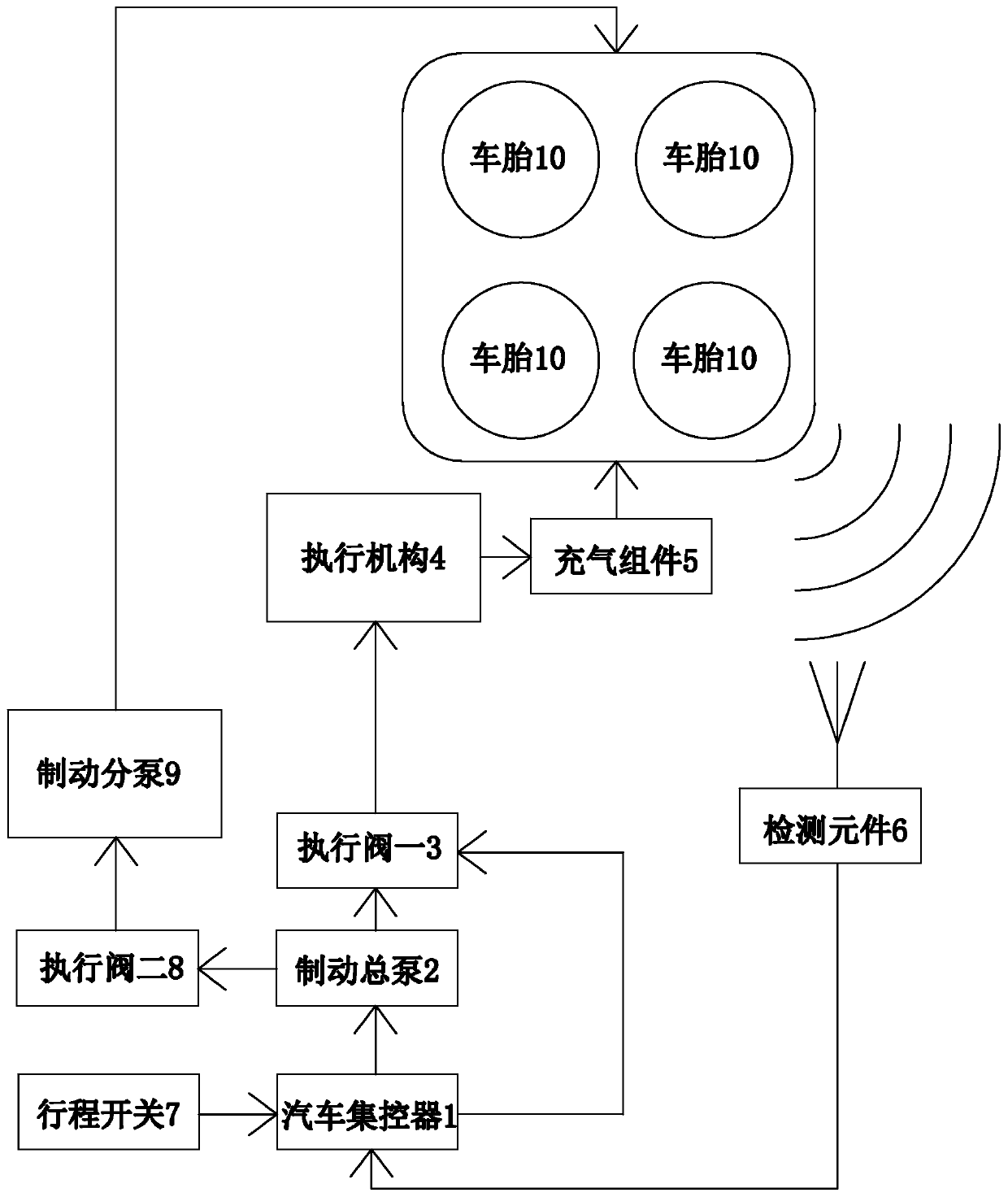

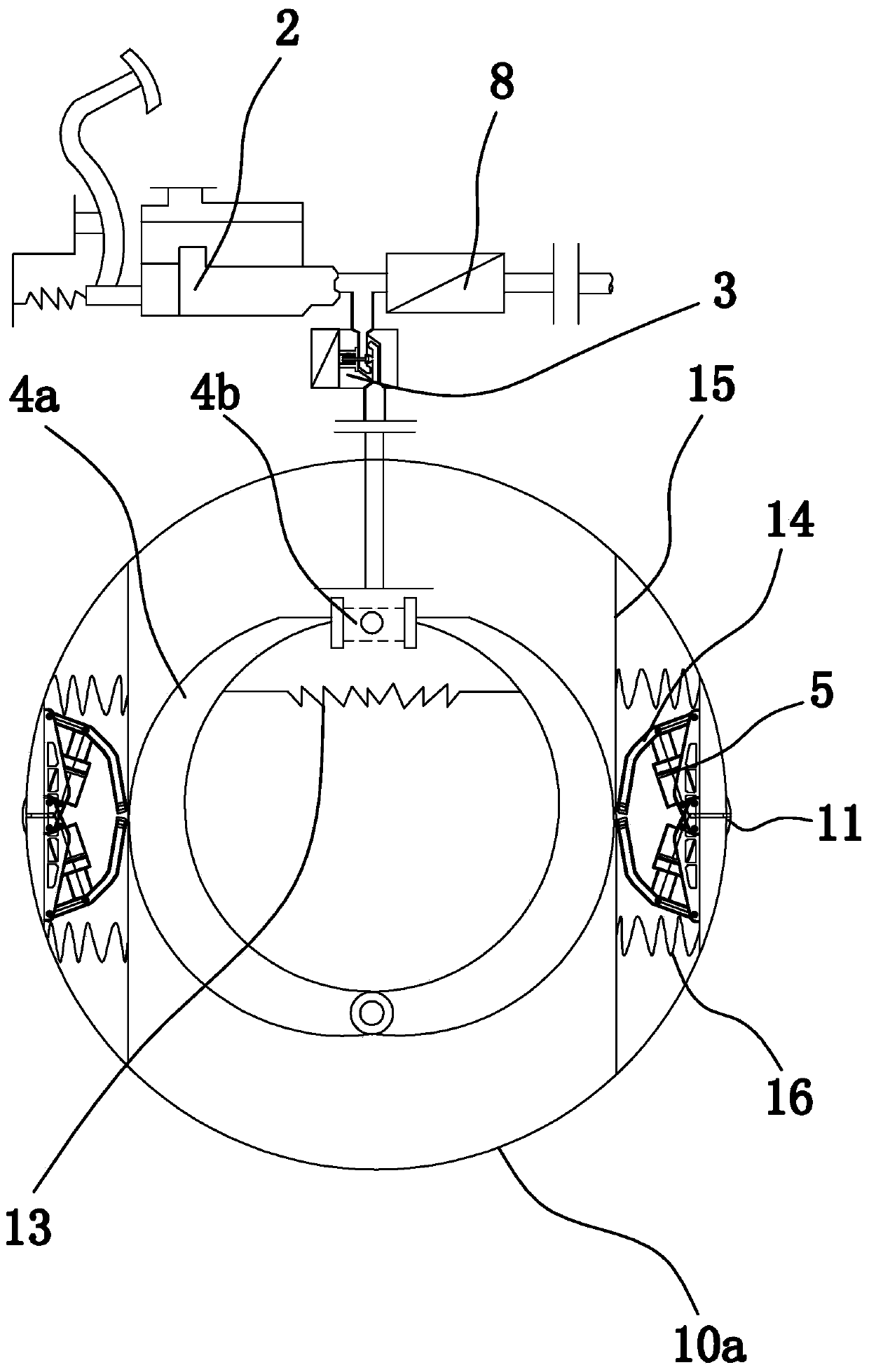

[0041] Such as Figure 1-3 As shown, the self-inflating constant pressure run-flat tire system includes a vehicle centralized controller, an actuator 4, a detection assembly 6 for detecting the tire pressure of each tire 10 of the vehicle, and an inflation assembly 5 fixed on each tire 10 of the vehicle. The vehicle centralized controller is an on-board ECU, and the detection component 6 includes a pressure sensor for detecting tire pressure and a receiver for receiving signals sent by the pressure sensor, and the receiver is electrically connected with the vehicle centralized controller.

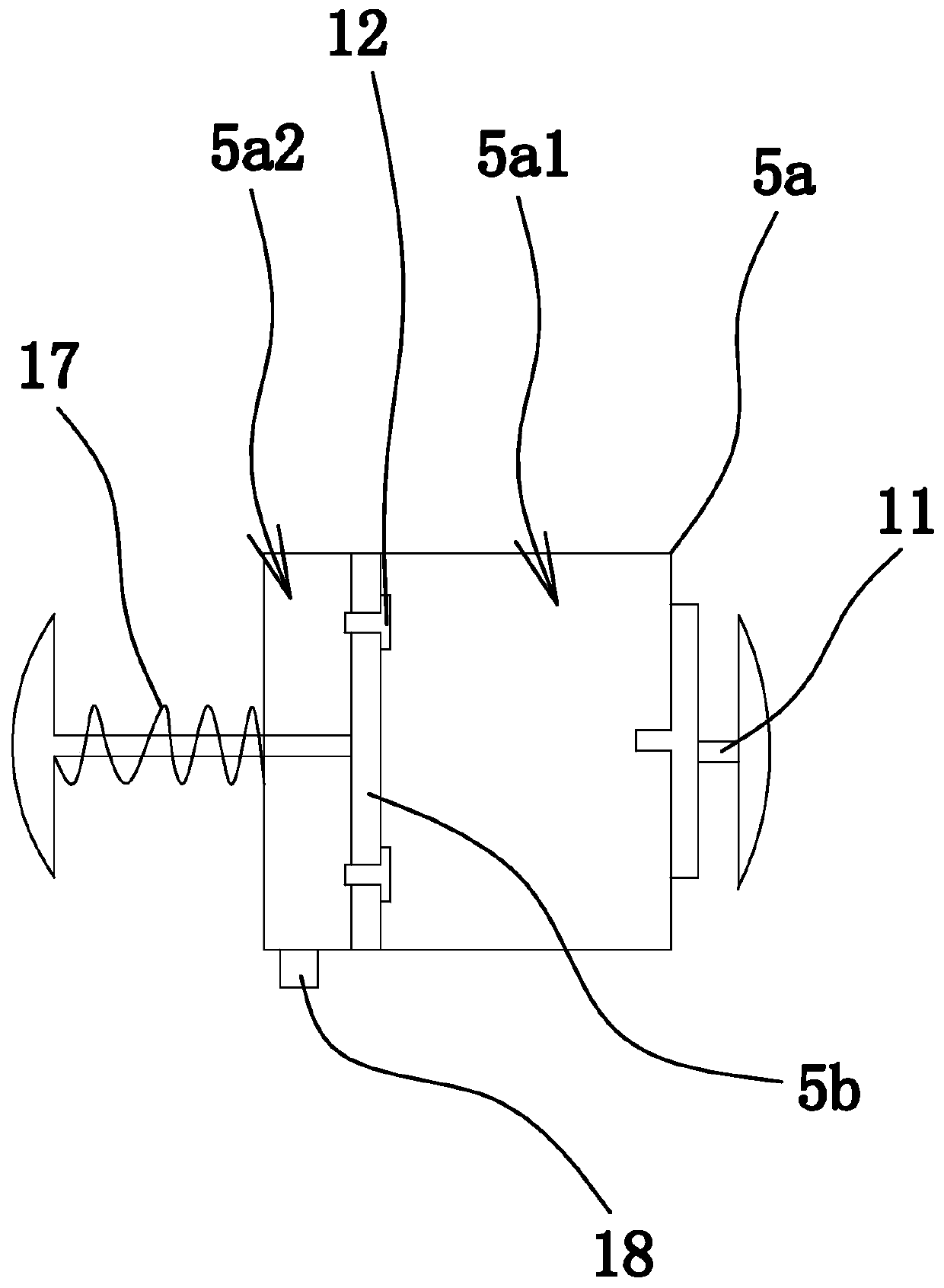

[0042] Specifically, each tire 10 is provided with two groups of inflatable components 5 , which are arranged symmetrically near the two sides of the corresponding wheel hub 10 a , and each group of inflatable components 5 includes at least two inflatable components 5 . In this embodiment, two inflatable assemblies 5 form a group. Each inflatable assembly 5 has a cylinder body 5a and a pis...

Embodiment 2

[0048] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: Figure 4 As shown, each group of inflatable components 5 includes an inflatable component 5, and a smooth pressurization guide plate 15 is also provided between each set of inflatable component 5 and the corresponding lever pressure bridge 4a. The hubs 10a are all connected by return springs 16. The piston 5b of the inflatable assembly 5 has a piston rod with one end protruding out of the cylinder body 5a. Swing outwards can be pressed on the steady pressure guide plate 15, and a return spring 17 that always makes the piston rod have a tendency to move outside the cylinder body 5a is also provided between the piston rod and the cylinder body 5a.

[0049] The detection component 6 sends the wheel pressure dynamics to the vehicle centralized controller in real time. The vehicle centralized controller performs real-time dynamic analysis and detection. When it is analyzed tha...

Embodiment 3

[0051] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: Figure 5 As shown, the actuator 4 includes two semicircular lever pressure bridges 4a. The middle parts of the two lever pressure bridges 4a are connected by a hydraulic part 4b that can push the two lever pressure bridges 4a to move relatively. Between and through one end, the piston 5b corresponding to the inflatable component 5 can be pushed to slide. The hydraulic component 4b can push the two lever pressure bridges 4a to move relative to each other, thereby pushing the corresponding piston 5b to slide to inflate, that is, to perform automatic inflation through the center expansion and opening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com