Graphene-based fabric for protection against pneumonia bacteria and preparation method thereof

A graphene and fabric technology, applied in the direction of rayon manufacturing, textile and paper making, single-component polyester rayon, etc., can solve the problem of unstable deposition uniformity, loss and waste of graphene oxide, load capacity and load uniformity There are still problems to be improved to achieve the effect of improving load fastness, improving antibacterial performance, and high load uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a graphene-based fabric for the protection of pneumonia bacteria, comprising the following steps:

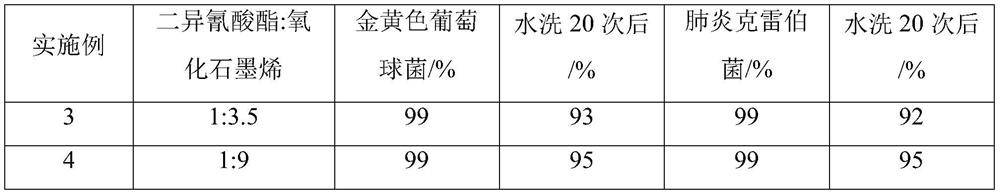

[0030] S1. Preparation of modified graphene: Dissolve graphene oxide in N,N-dimethylformamide, heat up to 80-90°C, and press the mass ratio of diisocyanate to graphene oxide to be 1:(3.5-9 ), add diisocyanate, react for 2-4h; then heat up to 90-100°C, add hydrazine hydrate for reduction reaction for 1-4h, centrifuge and wash to obtain modified graphene.

[0031] The diisocyanate is any one of hexamethylene diisocyanate, toluene diisocyanate or diphenylmethane diisocyanate.

[0032] In step S1, the isocyanate group of diisocyanate undergoes an addition reaction with the hydroxyl groups on the surface of graphene to form urethane groups, and then the graphene oxide is reduced with hydrazine hydrate to obtain diisocyanate-modified graphene. The mass ratio of diisocyanate to graphene oxide is preferably 1:(3.5-9), which not only ensures that the hydro...

Embodiment 1

[0052] A kind of graphene-based fabric for pneumonia bacteria protection is prepared through the following steps:

[0053] S1. Preparation of modified graphene

[0054] Dissolve graphene oxide in N,N-dimethylformamide, heat up to 85°C after ultrasonic dispersion, and add hexamethylene diisocyanate according to the mass ratio of diisocyanate to graphene oxide at 1:5. React for 3 hours; then raise the temperature to 95°C, add hydrazine hydrate to react for 2 hours, and reduce graphene oxide. After the reaction is complete, centrifuge and wash to obtain modified graphene;

[0055] S2. Preparation of modified polyester masterbatch

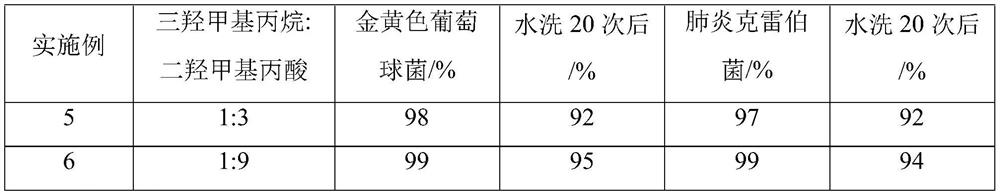

[0056] (1) Hydroxyl-terminated hyperbranched polyester oligomer: Add trimethylolpropane and dimethylol propionic acid with a molar ratio of 1:6 into the reaction vessel, and raise the temperature to 115°C under nitrogen protection, and react 3h, obtain terminal hydroxyl hyperbranched polyester oligomer;

[0057] (2) Carboxyl-terminated polyester oli...

Embodiment 2

[0066] The graphene-based fabric for the protection of pneumonia bacteria provided by embodiment 2 is prepared through the following steps:

[0067] S1. Preparation of modified graphene

[0068] Dissolve graphene oxide in N,N-dimethylformamide, heat up to 85°C after ultrasonic dispersion, and add hexamethylene diisocyanate according to the mass ratio of diisocyanate to graphene oxide at 1:5. React for 3 hours; then raise the temperature to 95°C, add hydrazine hydrate to react for 2 hours, and reduce graphene oxide. After the reaction is complete, centrifuge and wash to obtain modified graphene;

[0069] S2. Preparation of modified polyester masterbatch

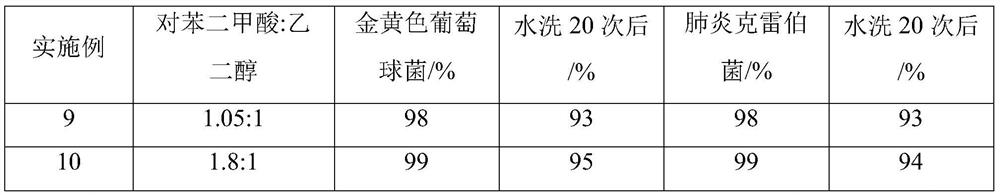

[0070] Preparation of modified polyester masterbatch: the modified graphene obtained in step S1 is added to the molten hydroxy-terminated ethylene terephthalate, and the amount of graphene added is the hydroxy-terminated ethylene terephthalate 0.5wt% of the alcohol ester, stirred and reacted at 280°C for 3h, so that the isoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com