Overhead roadbed structure, roadbed assembly, roadbed system and construction method

A construction method and subgrade technology, applied in the field of geotechnical engineering, can solve the problems of inconvenient operation and maintenance of track structure and grid structure, large foundation treatment area, and influence of grid safety, so as to achieve convenient operation and maintenance, filling The effect of less dosage and controllable construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

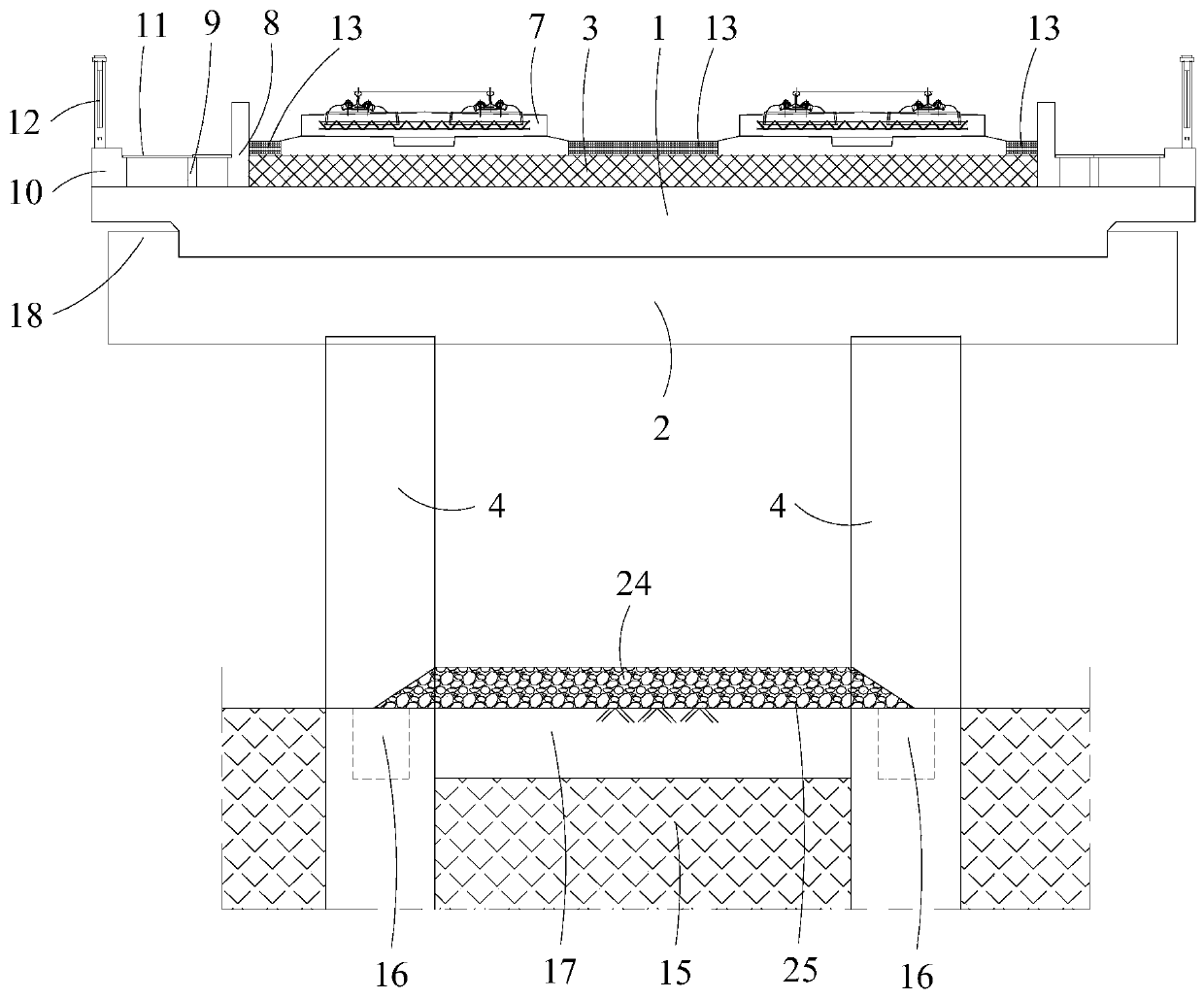

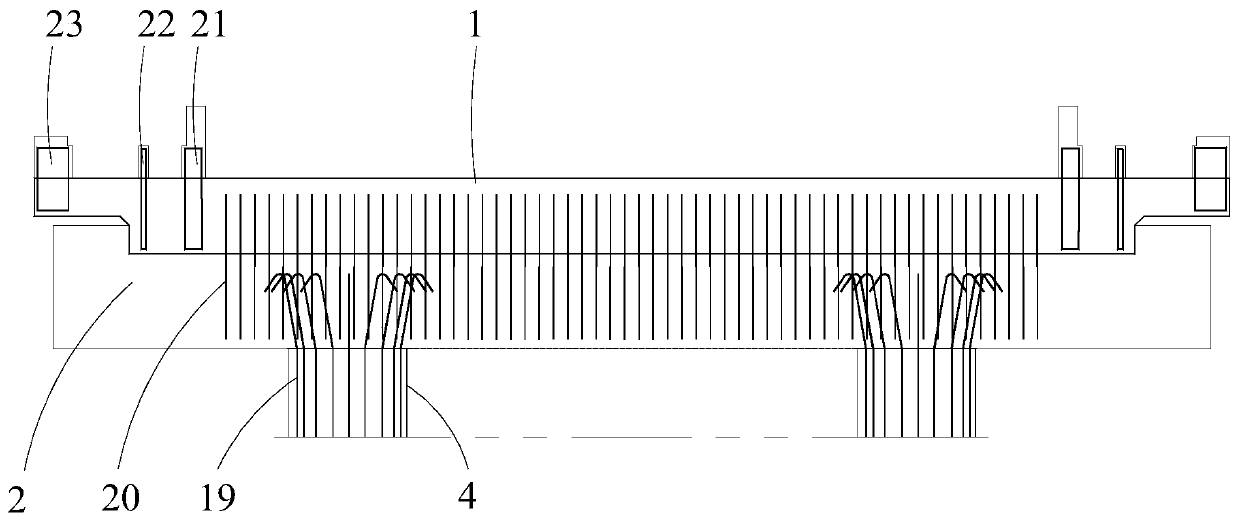

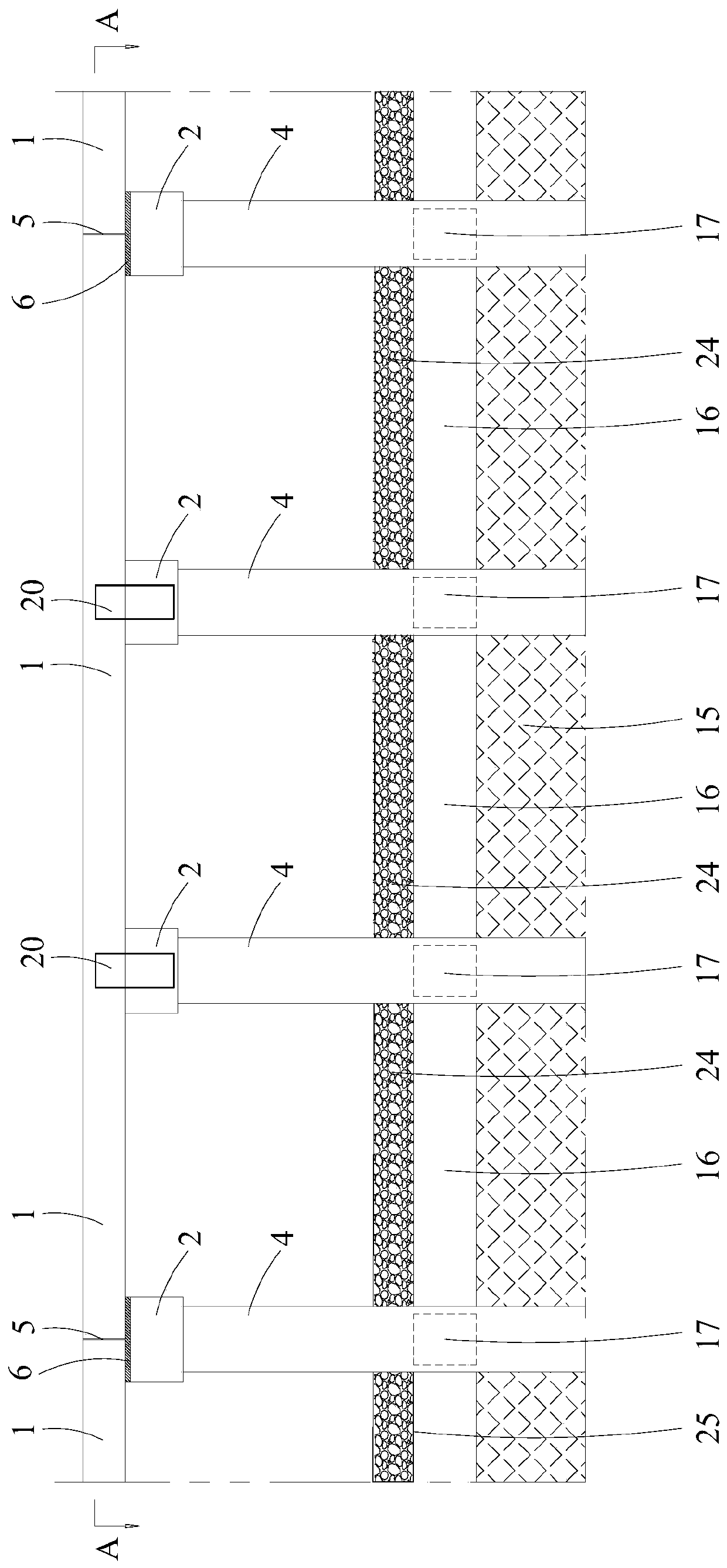

[0064] Such as Figure 1-4 As shown, the elevated subgrade structure described in this embodiment includes a bearing plate 1, and retaining walls 8 are respectively connected to both sides of the top surface of the bearing plate 1, and a foundation bed is filled between the two retaining walls 8 The surface layer 3, the bottom of the bearing plate 1 is provided with several joists 2, all the joists 2 are arranged at intervals along the length direction of the bearing plate 1, and the bottom of each joist 2 is arranged along the length direction of the joists 2 At least two pile foundations 4 are connected at intervals, and a track structure foundation 7 is arranged on the surface layer 3 of the foundation bed, and a buffer layer 13 is compacted between the track structure foundation 7 and the retaining wall 8, wherein, when the When there are at least two track structure foundations 7, a buffer layer 13 is also compacted between the adjacent track structure foundations 7

[0...

Embodiment 2

[0077] Such as Figure 1-4 As shown, in view of the existence of the existing technology, the subgrade structure of "filling + foundation treatment" often has uneven settlement of the auxiliary structures such as cable troughs and the main structure during use due to the use of filling construction, which often results in cable troughs. damage to auxiliary structures and water infiltration in the subgrade area; in addition, the construction technology of subgrade filling and rolling is greatly affected by weather changes, and the construction quality is not easy to control, and the excavation of the foundation is often There are a lot of spoil problems.

[0078] The elevated subgrade structure described in this embodiment differs from that of Embodiment 1 in that a protective railing is provided on the outside of the retaining wall 8 , and a maintenance railing is provided between the protective railing and the retaining wall 8 A channel, a cable channel vertical wall 9 is ar...

Embodiment 3

[0083] In the direction perpendicular to the length of the bearing plate 1, the joist 2 can limit the lateral displacement of the bearing plate 1;

[0084] In the length direction of the bearing plate 1, a sliding layer 6 is arranged between the two outermost joists 2 and the corresponding bearing plate 1, and the sliding layer 6 is used for the joist 2 and the The bearing plates 1 slide relative to each other, and at least one of the remaining joists 2 is connected to the bearing plate 1 .

[0085] However, in actual engineering, the connection between the joist 2 and the bearing plate 1 is mainly a rigid connection or a semi-rigid connection, wherein,

[0086] The rigid connection is: the joist 2 and the bearing plate 1 do not move relative to each other, nor rotate relative to each other;

[0087] Semi-rigid connection: under the condition that the stability can be ensured, the joist 2 and the bearing plate 1 do not move relative to each other, but relative rotation within...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com