Steel tube support and flange-type node connecting device of same

A steel pipe support and node connection technology, which is applied to the connection of scaffolding, the connection of formwork/formwork/work frame, the support of building structures, etc., can solve the problems of poor reliability of the frame, low efficiency of assembly and disassembly, and substandard fastening of nodes and other problems, to achieve the effect of reliable lateral support, high rotational stiffness of joints, and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

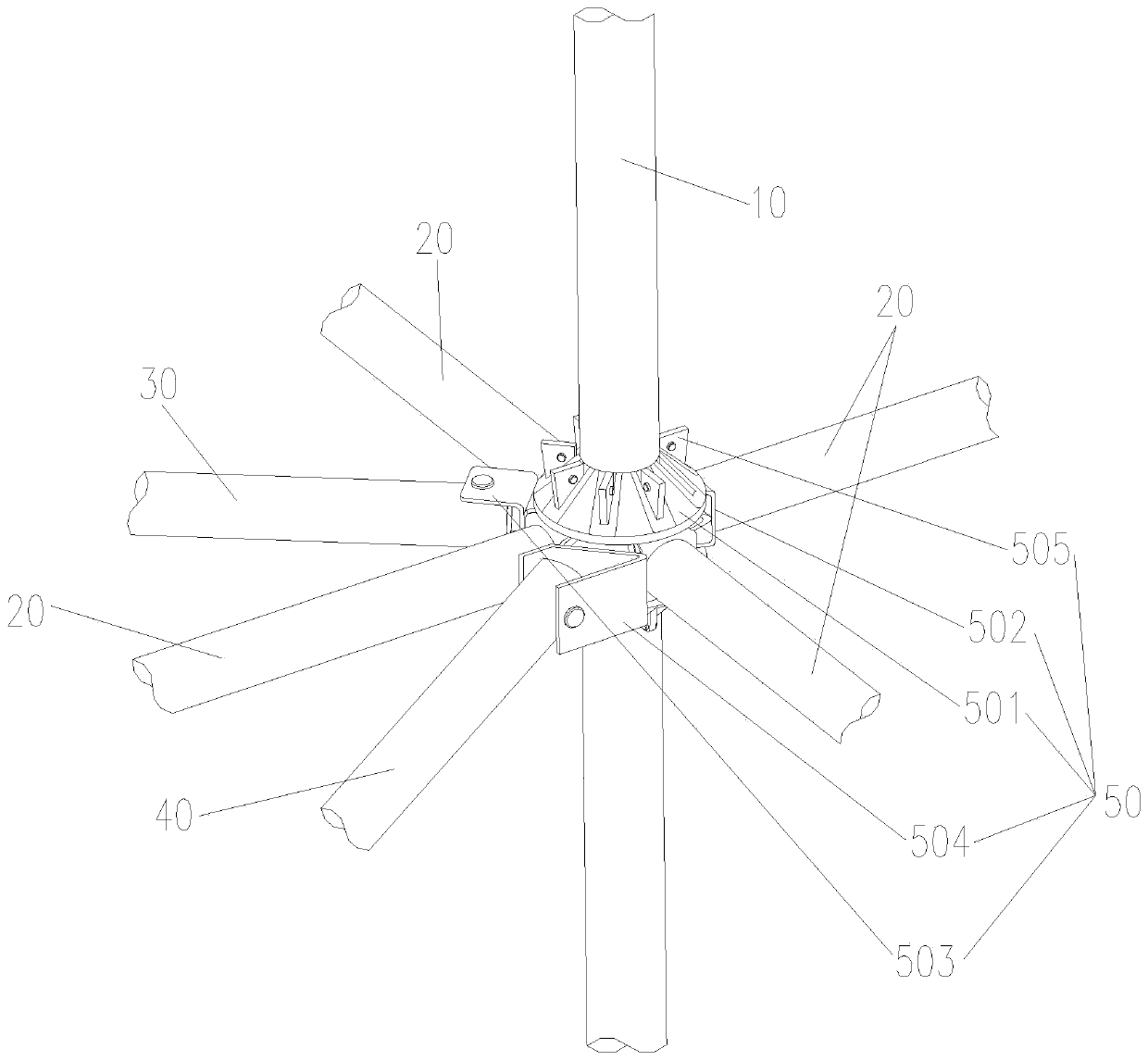

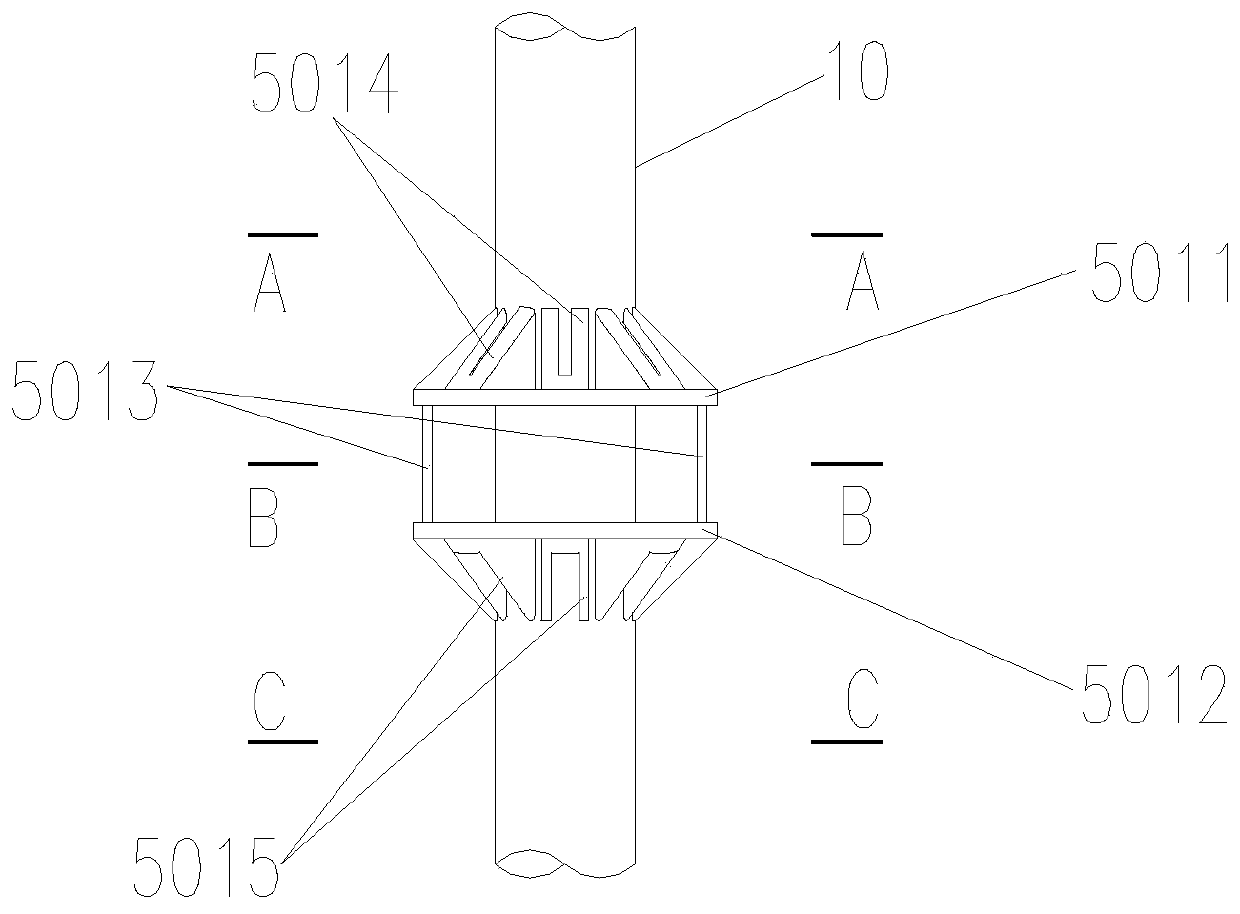

[0043] refer to figure 1 and Figure 10 , the steel pipe support provided by the present invention comprises: vertical bar 10, horizontal bar 20, plane slanting bar 30, facade slanting bar 40 and node connection device 50, wherein, node connection device 50 is made of flange plate socket 501, horizontal bar plug 502, plane oblique rod plug 503, façade oblique rod plug 504 and latch 505 form.

[0044] The specific structure of each part is introduced respectively below.

[0045] refer to figure 1 , Vertical bar 10, horizontal bar 20, plane inclined bar 30 and facade inclined bar 40 are all made of round steel pipes, and preferably galvanized round steel pipes, which can reduce the degree of internal and external corrosion of round steel pipes.

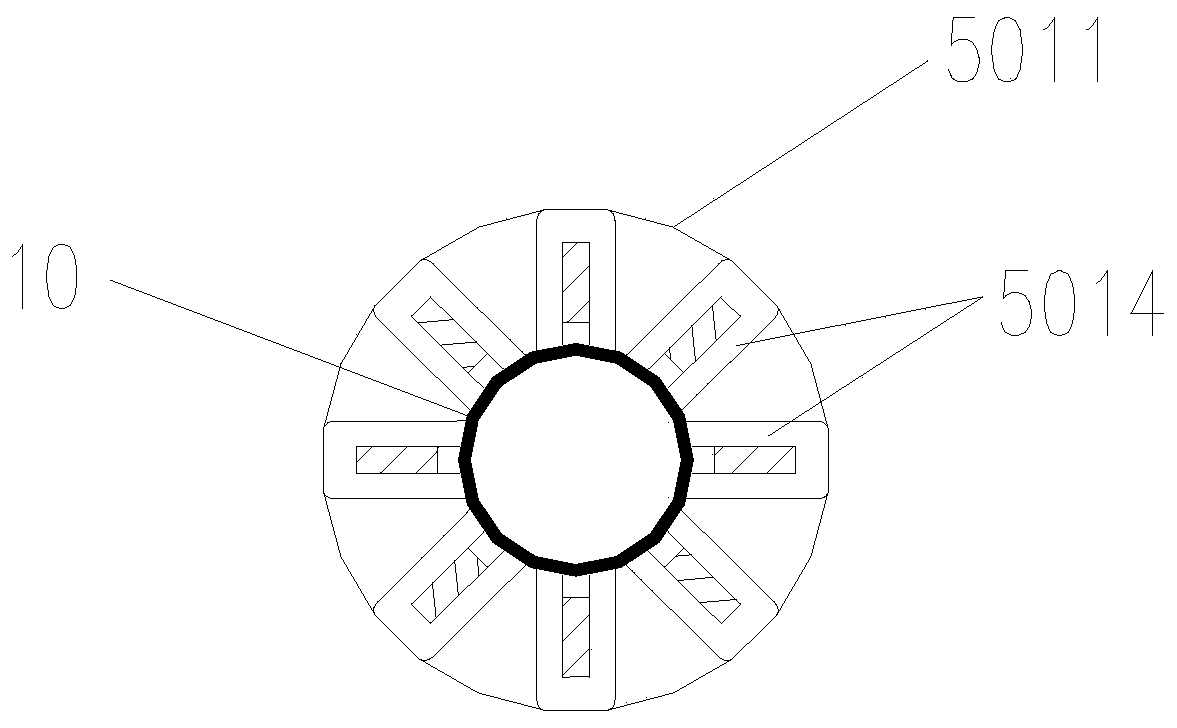

[0046] refer to Figure 2 to Figure 5 , the flange socket 501 is composed of an upper plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com