Three-blade ceiling fan cleaner

A technology of three-leaf ceiling fan and three-leaf ceiling fan blades, which is applied in the field of cleaners, can solve problems such as affecting vision, labor and effort, and air pollution, and achieve the effects of convenient cleaning or replacement, improved cleaning effect, and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

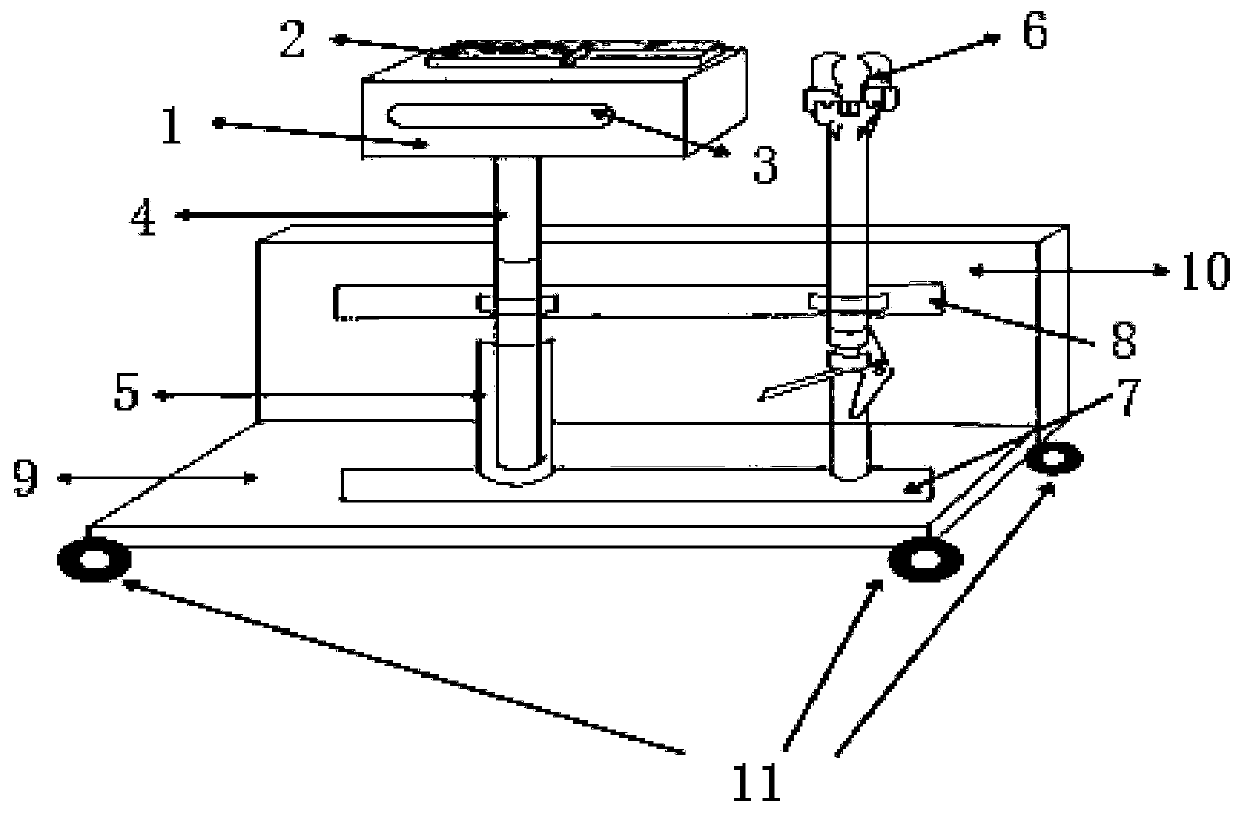

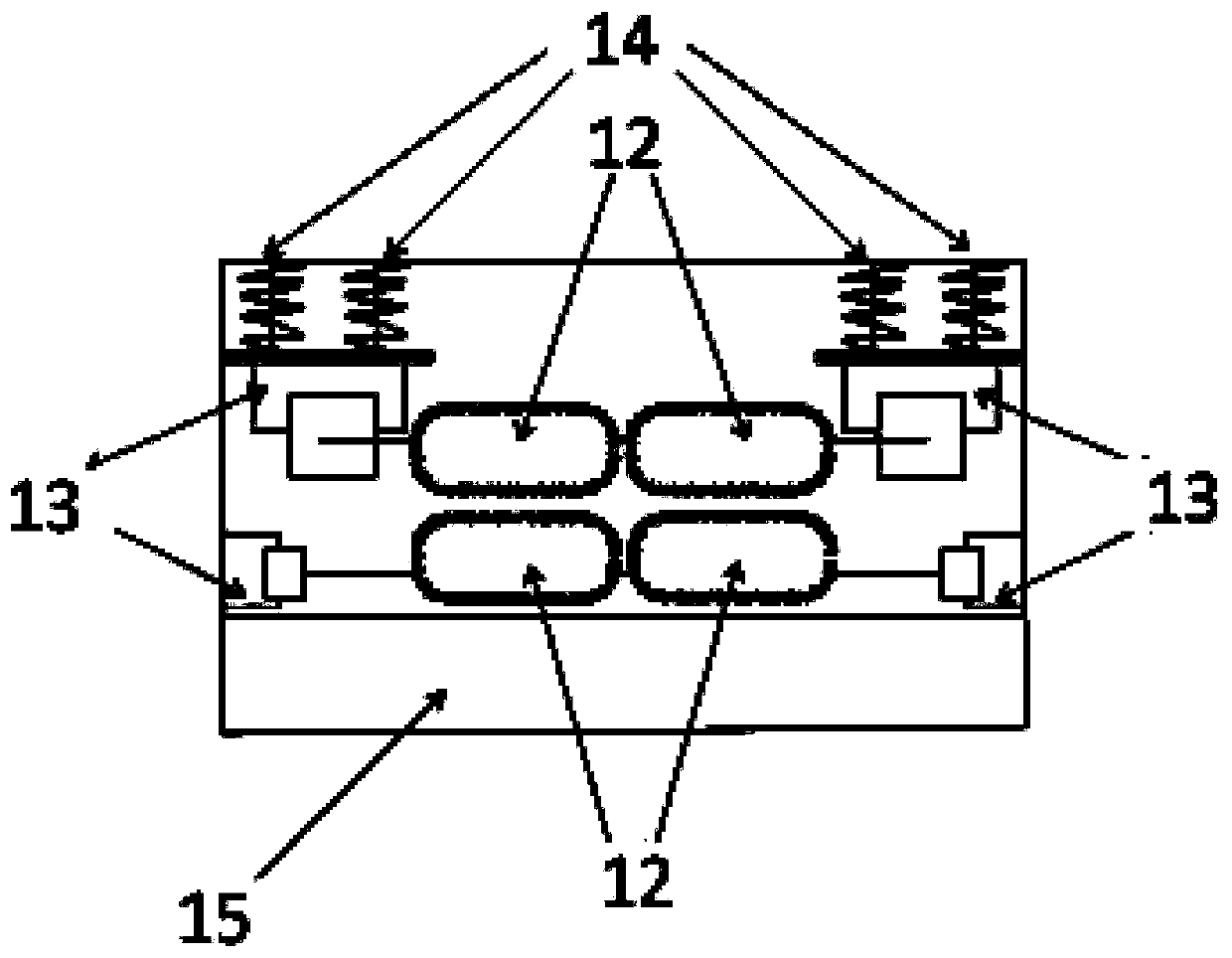

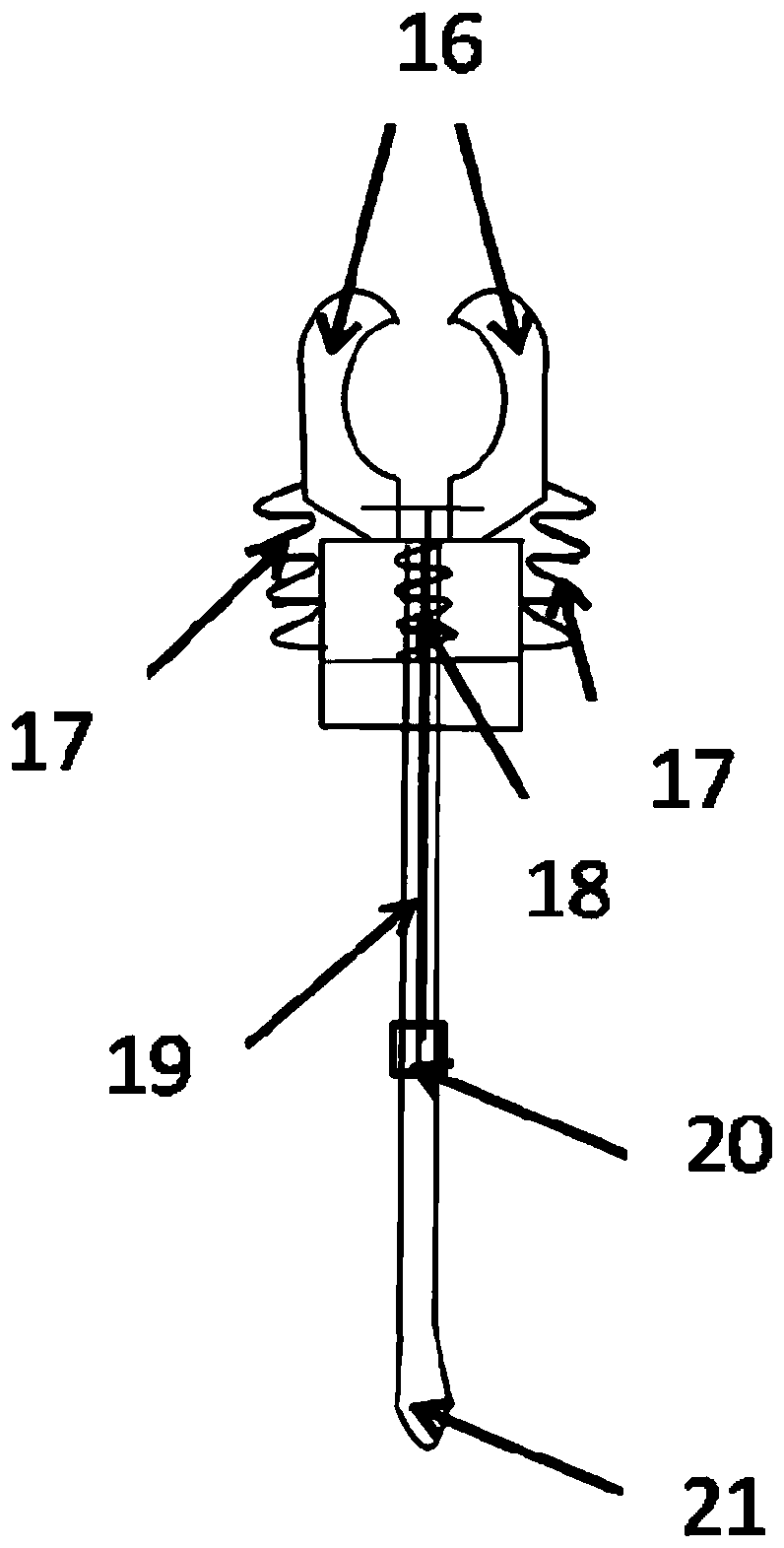

[0025] Such as figure 1 As shown, a three-leaf ceiling fan cleaner, the cleaner includes a cleaning bracket, and the clamping parts for fixing the root of the three-blade ceiling fan blade and the front surface of the three-blade ceiling fan blade are movable and arranged side by side on the cleaning bracket. The cleaning part of the stain on the reverse side, the clamping part includes a clamping telescopic rod 5 and a gripper 6, the gripper 6 is fixed on the top of the clamping telescopic rod 5, the cleaning part includes a cleaning telescopic rod 4 and a cleaning box 1, and the cleaning box 1 is fixed on the cleaning On the top of the telescopic rod 4, the side of the cleaning box 1 is provided with a wiping hole 3 for extending the blades of the three-leaf ceiling fan into the interior of the cleaning box 1, and the cleaning box 1 is provided with a wiping component for automatically wiping the stains on the front and back of the three-blade ceiling fan blades ;

[0026] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap