Three-dimensional stress sensor based on circularly polarized liquid metal antenna

A circularly polarized antenna, liquid metal technology, applied in the direction of instruments, measuring force, measuring force components, etc., can solve the problems of inability to monitor three-way stress, complex pressure conversion process, poor reliability and accuracy, etc., to save manpower , Reduce the influence of multipath reflection, improve the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

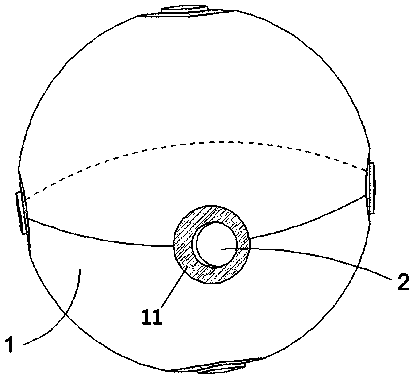

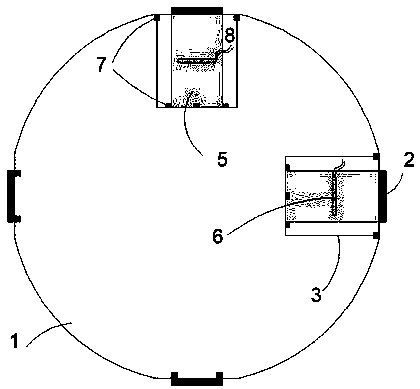

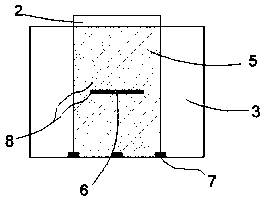

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes a box body 1, a housing 3 and a circularly polarized antenna structure 4. The six sides of the box body 1 are symmetrically provided with openings, and the inner side of the surface where each opening is located is fixed with a housing. 3. The surface where the orifice is located can be an arc surface or a plane; the circularly polarized antenna structure 4 is installed in the inner cavity of the housing 3, and the inner cavity of the housing is reserved for the deformation of the circularly polarized antenna structure 4. Space, the top surface of the circularly polarized antenna structure 4 is close to the upper cover 2, and the upper cover 2 slides out of the top opening of the housing 3, just like the cooperation between the button contact and the button hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com