High-speed train wheel set damage identification test bed based on wheel vibration acceleration response

A vibration acceleration and damage identification technology, applied in vibration testing, railway vehicle testing, machine/structural component testing, etc., can solve problems such as low feasibility and accuracy of axle status identification, failure to complete damage identification and load identification, etc. , to achieve the effect of reducing expensive costs, light weight, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

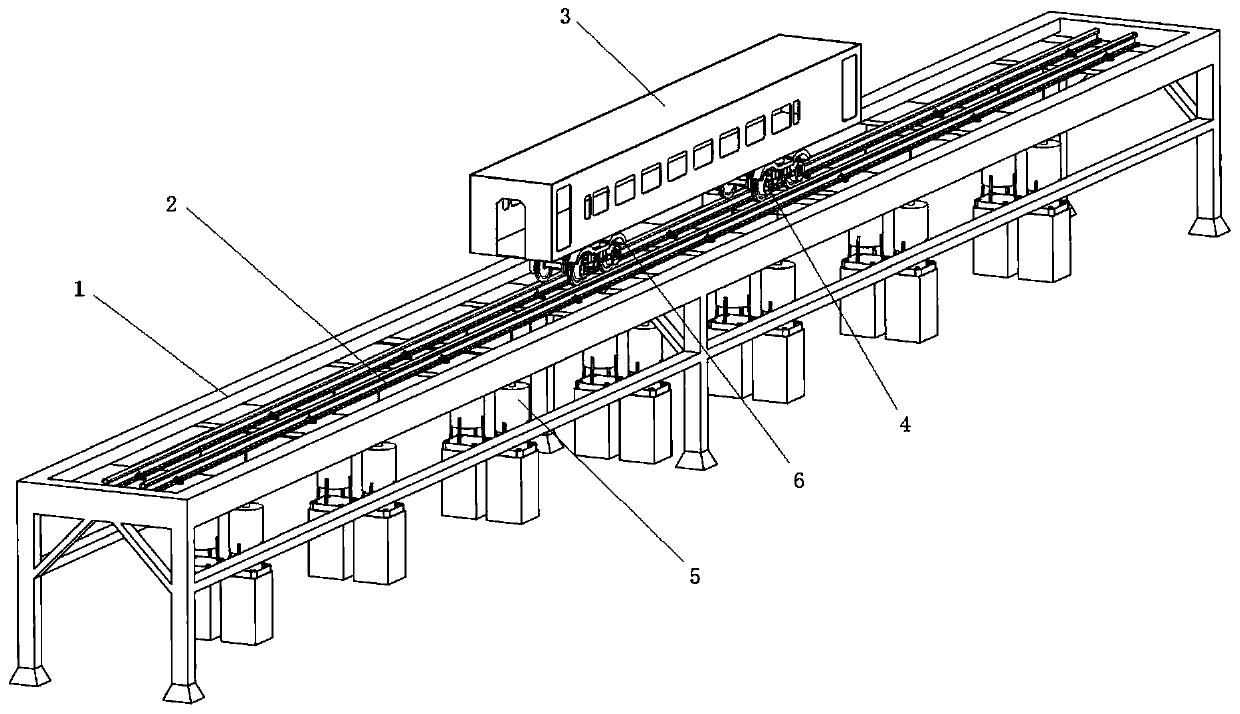

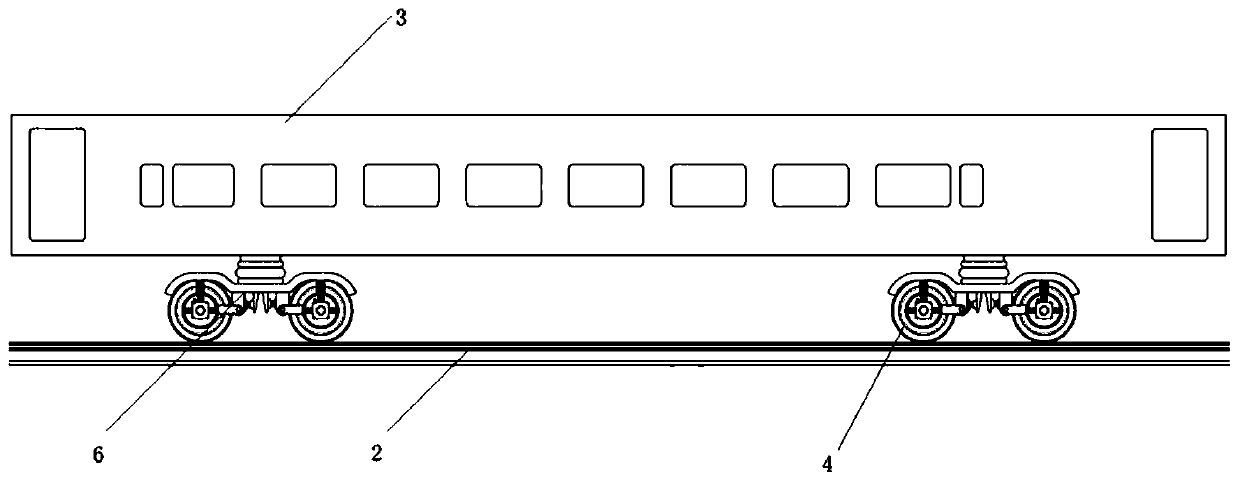

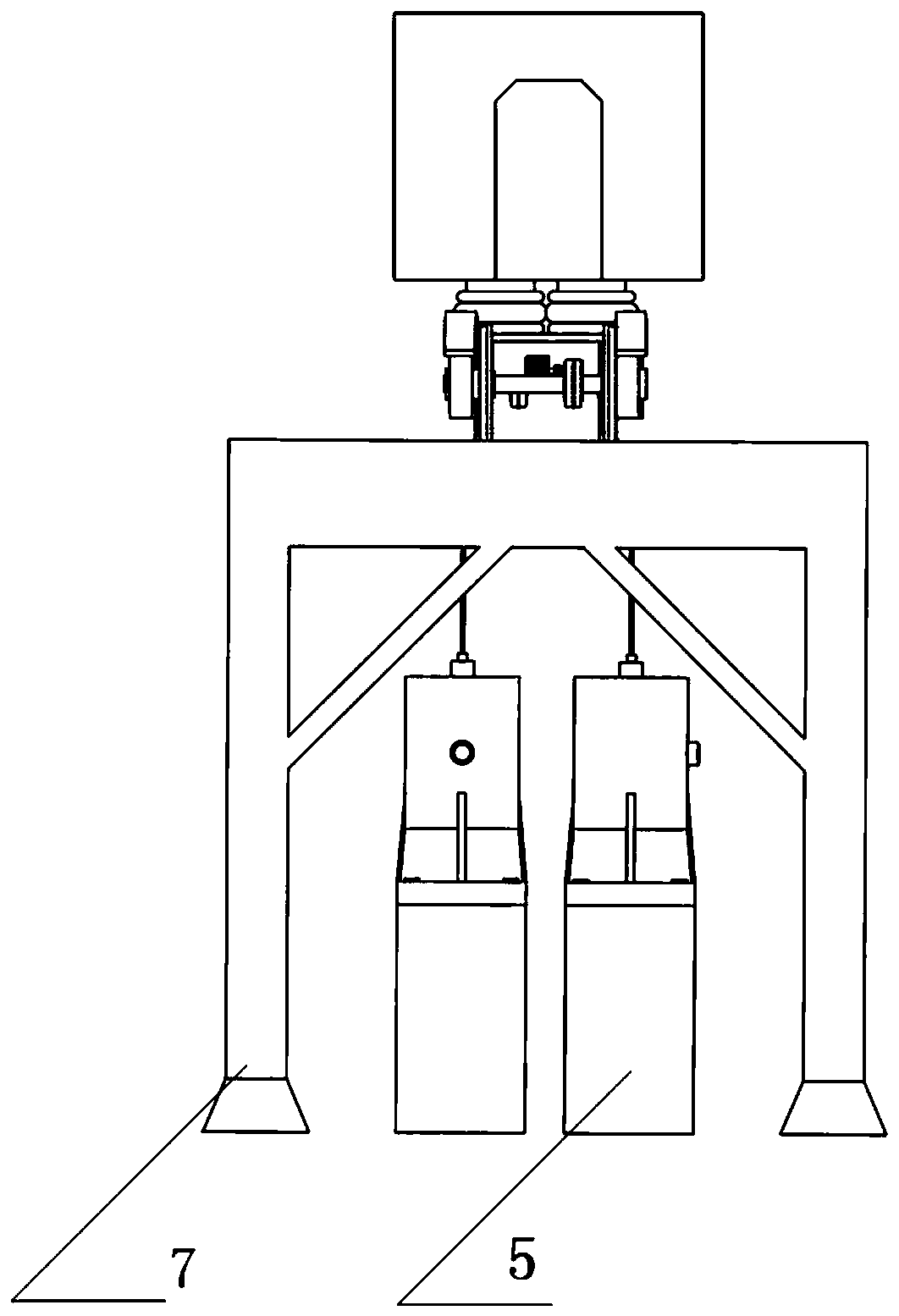

[0065] Such as figure 1 , figure 2 , image 3 , Image 6 As shown, the wheel set damage identification test bench based on the wheel vibration acceleration response disclosed by the present invention includes a proportional bogie 6, a proportional car body 3, a proportional track 2, a power loading and control system, a data acquisition system, signal processing and analysis system,. The scale car body 3, the wheel set 4, and the scale bogie 6 are all 1:8 scale models of the actual size of the high-speed train. The scale car body 3 is made of aluminum, and the scale car body 3 is connected to the wheel set 4 through the scale bogie 6. The control system includes a vertical vibrator 5, and the vertical vibrator 5 acts on the bottom of the proportional track 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com